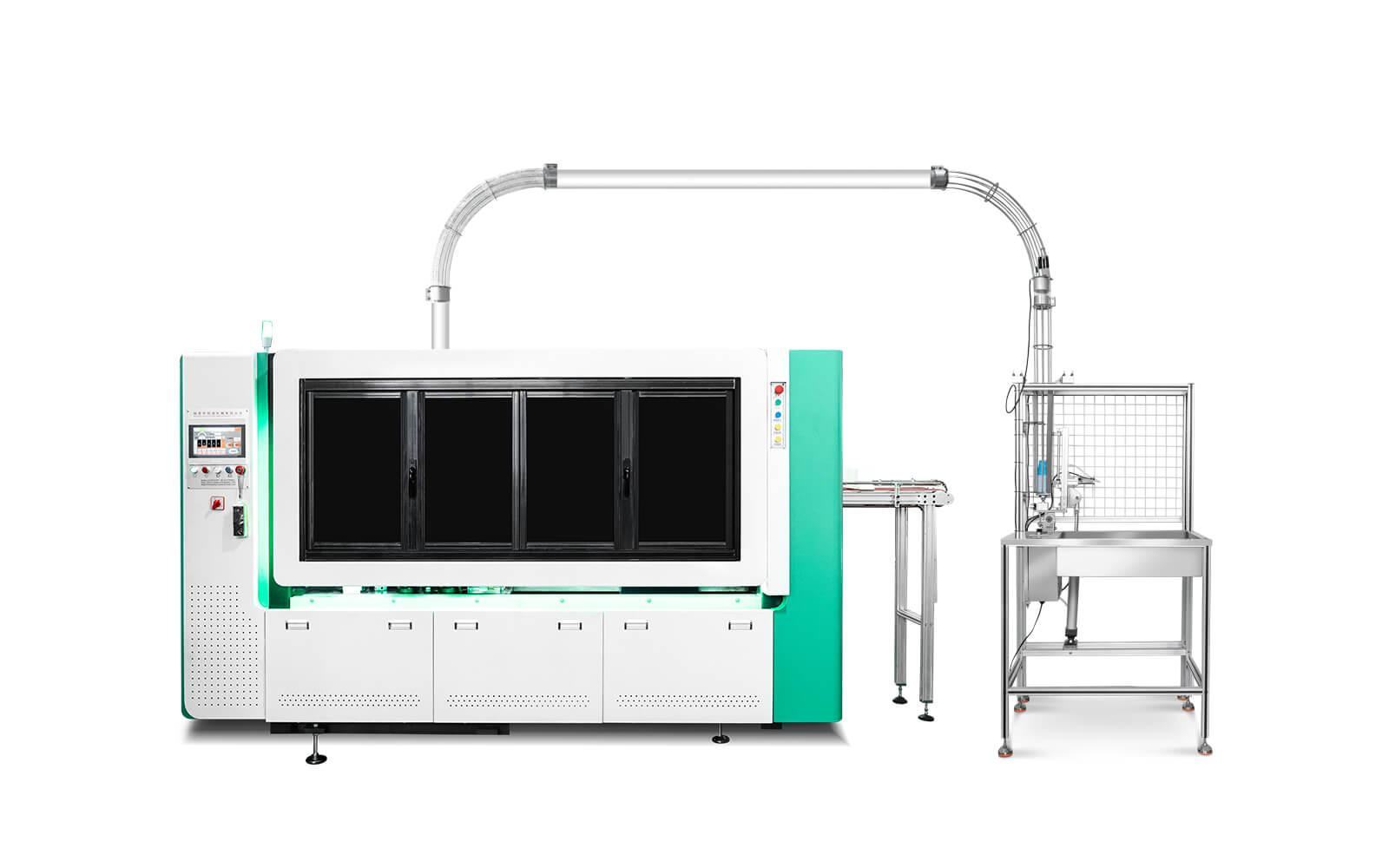

Paper Cup Machine

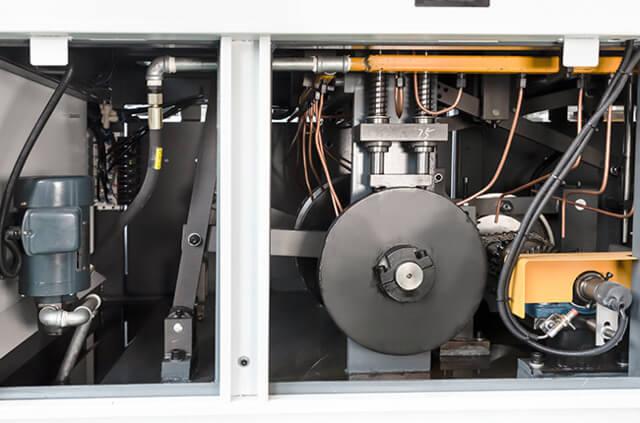

MYC-0CM12 Simple Ultrasonic Heating Paper Cup Machine

MYC-OCM100 High Speed Simple Model Paper Cup Machine

MYC-OCM12 High Speed Intelligent Paper Cup Machine

MYC-120S Double Disc Design Ultrasonic Paper Cup Machine

MYC-180S Full Servo Intelligent Paper Cup Machine

MYC-DW120 Automatic Paper Cup Sleeve Machine

MYC-D Automatic Simple Double Wall Paper Cup Machine

MYC-OCM100 Disposable Paper Cup Forming Machine

MYC-DW100 Double Wall Paper Cup Sleeve Making Machine

MYC-160S Seven Servo Motors Paper Cup Machine

Paper Plate Machine

MY-ZDJ800 Special-Shaped Paper Plate Machine

MYC-ZDJ1000 Automatic High Speed Paper Plate Machine

MY-ZDJ1200 Full servo double station food paper plate machine

Paper Bowl Machine

MY-OCBUCKET Automatic Salad Paper Bowl Machine

MY-W35 Automatic Paper Bowl Forming Machine

Paper Cup Packaging Machine

MY-600X Automatic Paper Cup Packaging Machine

MY-800 Paper Cup Sling Type Packing Machine

Cup Lid Machine

MYC-420G Automatic High Speed Plastic Lid Machine

MYC-ZG100 Full automatic Paper Lid Making Machine

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

DW120 works perfectly with MYC-120SLily 2024-05-22

The paper cup machine has exceeded our expectations in every way. It's a high-performance product that has transformed our production process.Mia 2024-05-24

The investment in this paper cup machine has been worth every penny – our customers love the cups!Aurora 2024-06-05

The paper cup machine has been a game-changer for our production line. It's efficient, precise, and has elevated our output quality.Ava 2024-05-23