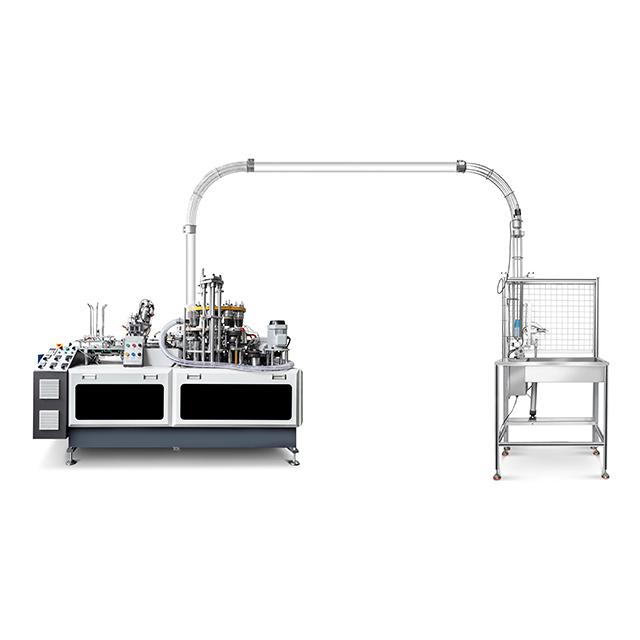

Mini paper cup making machines are essential equipment for businesses that produce paper cups on a small scale. These machines are compact, efficient, and user-friendly, making them ideal for small businesses, cafes, and even household use. However, proper installation and maintenance of these machines are crucial to ensure smooth operation and longevity.

1. Unpacking and Inspection

Upon receiving your mini paper cup making machine, carefully unpack the components and inspect them for any damage that may have occurred during shipping. Make sure all parts are included as per the manufacturer's checklist to avoid any issues during installation.

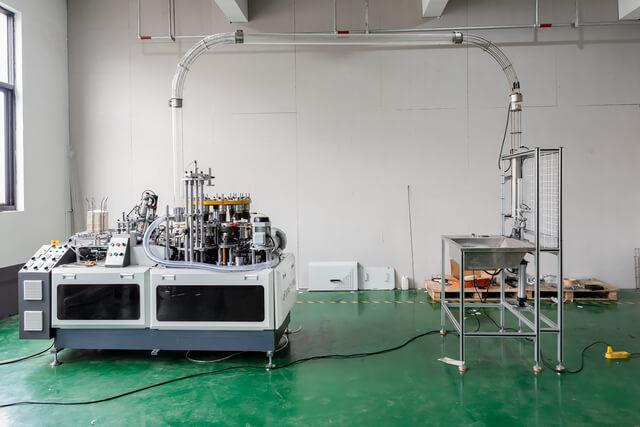

2. Installation of the Machine

Place the machine on a stable and level surface in a well-ventilated area. Follow the manufacturer's instructions for connecting the power supply and ensuring all safety precautions are in place. It is essential to have the machine installed correctly to prevent any accidents or malfunctions.

3. Calibration and Testing

After installation, calibrate the machine according to the specifications provided by the manufacturer. Test the machine with a small batch of paper cups to ensure it is functioning correctly. Make any necessary adjustments to the settings to achieve the desired cup quality.

4. Regular Cleaning and Maintenance

Regular cleaning and maintenance are key to the longevity of your mini paper cup making machine. Clean the machine after each use to prevent the buildup of paper dust and debris. Lubricate moving parts as recommended by the manufacturer to avoid wear and tear.

5. Troubleshooting Common Issues

If you encounter any problems with your machine, refer to the user manual for troubleshooting tips. Common issues such as paper jams, misaligned parts, or inconsistent cup formation can often be resolved with simple adjustments or cleaning. Do not attempt major repairs unless you are trained to do so.

6. Replacement of Parts

Over time, certain parts of the mini paper cup making machine may wear out and need replacement. Keep an inventory of spare parts provided by the manufacturer and replace worn-out components promptly to avoid disruptions in production. Consult with the manufacturer for guidance on part replacements.

7. Safety Precautions

Always follow safety guidelines while operating the mini paper cup making machine. Avoid touching moving parts while the machine is in operation and use protective gear such as gloves and goggles when necessary. Keep children and pets away from the machine to prevent accidents.

8. Training and Support

Ensure that operators using the mini paper cup making machine are properly trained in its operation and maintenance. Provide ongoing support and training to keep up with any software updates or new features introduced by the manufacturer. A well-trained team will help maximize the efficiency of the machine.

Conclusion

Proper installation and maintenance of a mini paper cup making machine are essential for its efficient operation and longevity. By following the manufacturer's guidelines, conducting regular maintenance, and addressing any issues promptly, you can ensure that your machine produces high-quality paper cups consistently. Remember to prioritize safety and invest in training for your team to get the most out of your mini paper cup making machine.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China