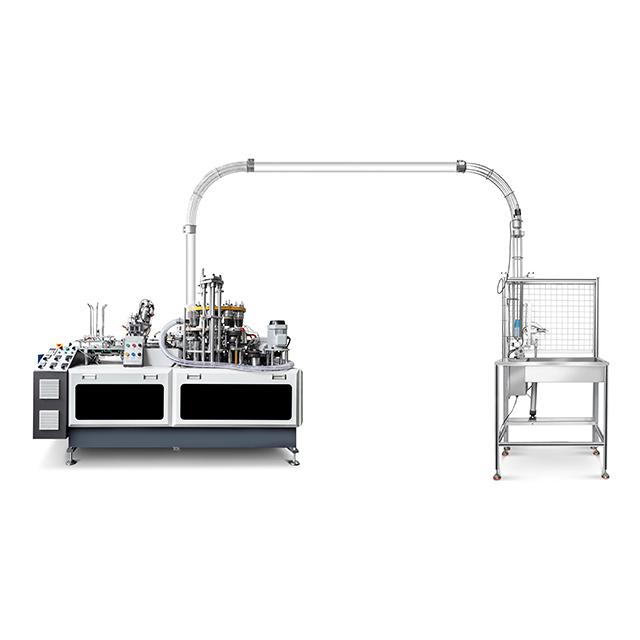

Paper Cup Machine

MYC-0CM12 Simple Ultrasonic Heating Paper Cup Machine

MYC-OCM100 High Speed Simple Model Paper Cup Machine

MYC-OCM12 High Speed Intelligent Paper Cup Machine

MYC-120S Double Disc Design Ultrasonic Paper Cup Machine

MYC-180S Full Servo Intelligent Paper Cup Machine

MYC-DW120 Automatic Paper Cup Sleeve Machine

MYC-D Automatic Simple Double Wall Paper Cup Machine

MYC-OCM100 Disposable Paper Cup Forming Machine

MYC-DW100 Double Wall Paper Cup Sleeve Making Machine

MYC-160S Seven Servo Motors Paper Cup Machine

Paper Plate Machine

MY-ZDJ800 Special-Shaped Paper Plate Machine

MYC-ZDJ1000 Automatic High Speed Paper Plate Machine

MY-ZDJ1200 Full servo double station food paper plate machine

Paper Bowl Machine

MY-OCBUCKET Automatic Salad Paper Bowl Machine

MY-W35 Automatic Paper Bowl Forming Machine

Paper Cup Packaging Machine

MY-600X Automatic Paper Cup Packaging Machine

MY-800 Paper Cup Sling Type Packing Machine

Cup Lid Machine

MYC-420G Automatic High Speed Plastic Lid Machine

MYC-ZG100 Full automatic Paper Lid Making Machine

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China