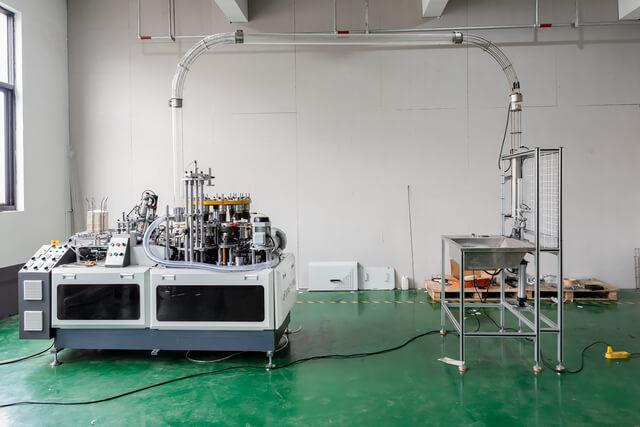

High speed paper cup machines are essential equipment for producing disposable paper cups in large quantities. To ensure the efficient operation of a high speed paper cup machine and prolong its lifespan, proper maintenance and care are crucial. By following a regular maintenance schedule and implementing best practices in care, you can optimize the performance of your machine and reduce the risk of breakdowns.

1. Daily Cleaning Routine

One of the key aspects of maintaining a high speed paper cup machine is to establish a daily cleaning routine. After each production run, make sure to thoroughly clean all components of the machine, including the forming molds, heating elements, and conveyor belts. Use appropriate cleaning solutions and tools to remove any paper residue, grease, or dust that may accumulate during operation.

2. Lubrication of Moving Parts

Regular lubrication of the moving parts is essential to prevent friction and wear in a high speed paper cup machine. Refer to the manufacturer's guidelines to identify the specific lubricants recommended for different components. Apply lubricants to the designated areas at scheduled intervals to ensure smooth operation and reduce the risk of mechanical failures.

3. Inspection of Electrical Systems

Periodic inspections of the electrical systems are crucial to maintain the safety and efficiency of a high speed paper cup machine. Check for any loose connections, damaged wires, or worn-out components that could pose a risk of electrical hazards or malfunctions. Engage qualified technicians to perform thorough inspections and address any issues promptly.

4. Calibration of Machine Settings

Calibrating the machine settings regularly is important to ensure the accurate production of paper cups with consistent quality. Check the temperature settings, speed controls, and other parameters to ensure they are optimized for the type of paper and coating being used. Make adjustments as needed to achieve the desired output.

5. Training for Operators

Proper training for machine operators is essential to ensure that they understand the maintenance procedures and operating protocols of a high speed paper cup machine. Provide comprehensive training on cleaning routines, troubleshooting techniques, and safety precautions. Encourage operators to report any abnormalities or concerns promptly.

6. Replacement of Worn-Out Parts

Over time, certain components of a high speed paper cup machine may wear out due to continuous use. Keep an inventory of spare parts and regularly inspect the condition of critical components such as forming dies, sensors, and motors. Replace any worn-out parts promptly to prevent disruptions in production.

7. Monitoring Production Performance

Regularly monitoring the production performance of a high speed paper cup machine can help identify potential issues early on and prevent major breakdowns. Keep track of production outputs, reject rates, and machine downtime to assess the overall efficiency. Analyze trends and implement improvements to optimize performance.

8. Scheduled Maintenance Checks

Establishing a scheduled maintenance program is essential to keep a high speed paper cup machine in optimal condition. Create a maintenance calendar with predefined tasks such as cleaning, lubrication, inspections, and part replacements. Adhere to the schedule diligently to ensure the long-term reliability of the machine.

Conclusion

Maintaining and caring for a high speed paper cup machine is essential to ensure its reliable performance and longevity. By following a comprehensive maintenance routine, including daily cleaning, lubrication, inspections, and calibration, you can maximize the efficiency of the machine and minimize downtime. Investing in operator training, monitoring production performance, and scheduling regular maintenance checks are key strategies to keep your machine running at its best. Remember, proactive maintenance is the key to avoiding costly repairs and ensuring uninterrupted production of high-quality paper cups.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China