In paper cup production, it is very important to select high-quality raw materials because it directly affects the quality and performance of the product. Only raw materials that meet the standards can give full play to the performance of paper cup machines. Paper cup machines transform food-grade paper, coating and base paper into strong and durable paper cups through precise processing and forming processes.

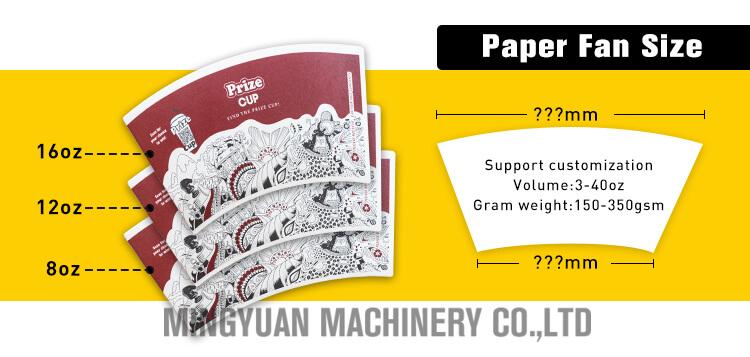

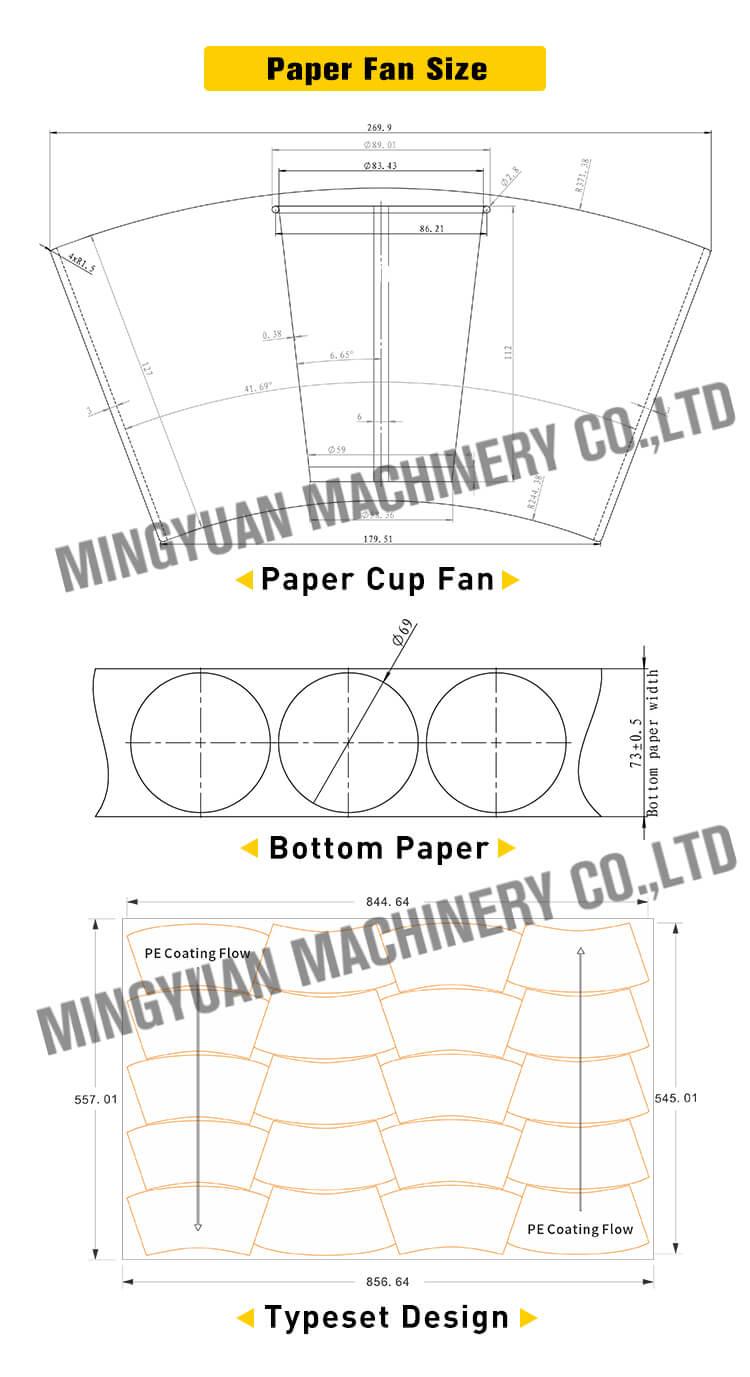

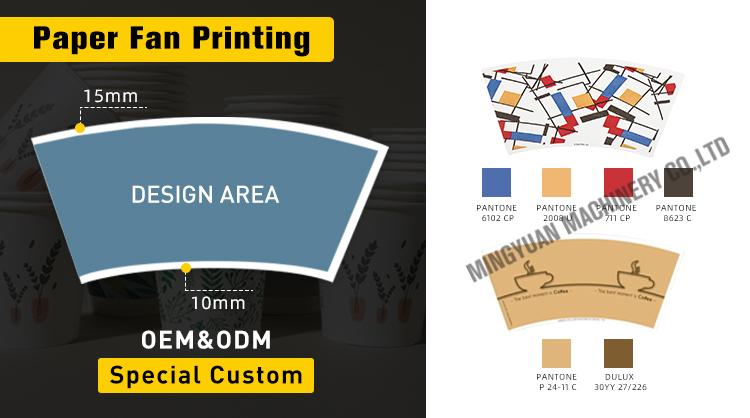

1. Design Size And Pattern

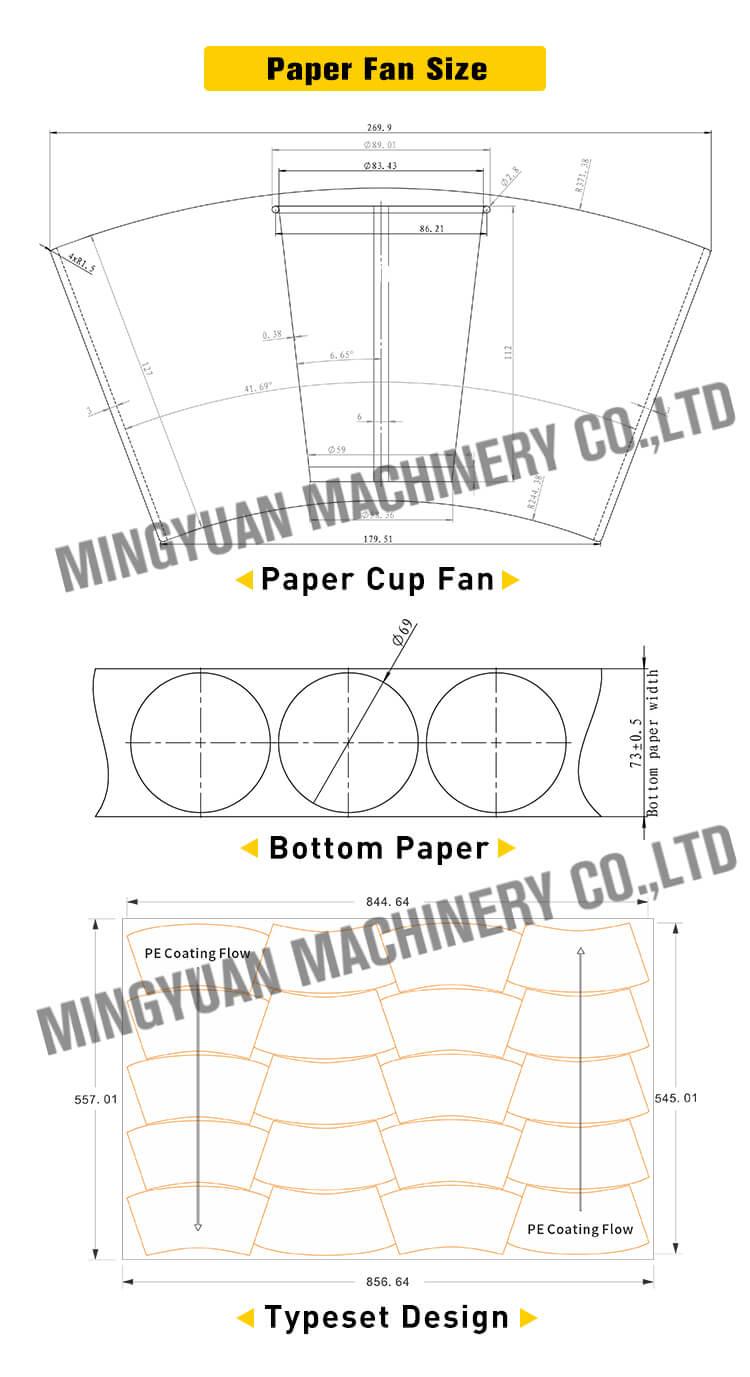

In the initial communication, we will learn about your paper cup needs in detail, including information such as purpose, size and capacity. You can send samples to our engineers so that they can accurately measure the size and design a detailed size drawing based on the actual sample.

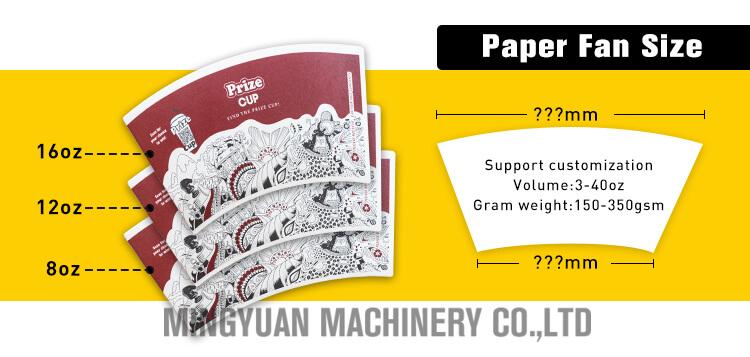

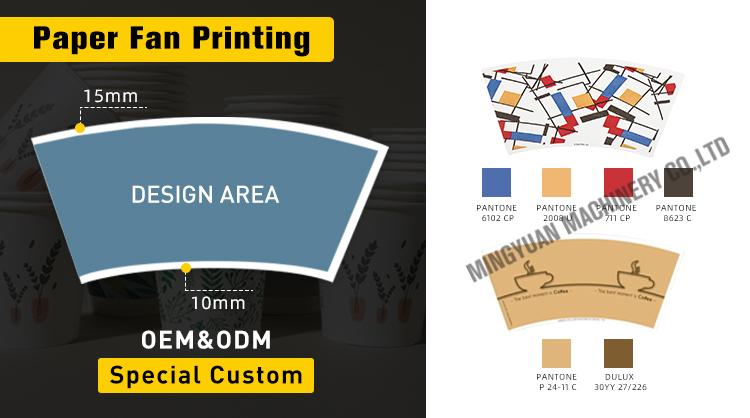

The paper cup fan adopts a three-sided blank design for sticking, sealing and curling, and the middle part is your customization area. We will make a preliminary design sketch according to your pattern requirements, including color, design details and brand logo. We use environmentally friendly food-grade ink for printing, ensuring bright colors and no ink odor. In addition, we support multi-color printing options, up to 1-6 colors.

Through these steps, we can precisely adjust the size and pattern of the paper cup to meet your design needs, ensuring the best visual effect and functionality. After the sample is made, you can make a detailed evaluation. In order to better demonstrate our capabilities, the above are the paper fan samples we customized for other customers.

2. Determine Material Requirements

When determining the material requirements for paper cups, you first need to clarify the usage scenarios of paper cups, including purpose and environmental conditions, in order to select appropriate paper and coating. Choose food-grade paper according to the purpose, and determine the thickness and strength of the paper to ensure the durability of the paper cup. Secondly, ensure the compatibility of the selected material with the paper cup machine to ensure smooth production, because not all types of paper are suitable for processing by paper cup machines.

In terms of coating, if paper cups are used for hot drinks or require strong waterproof properties, it is more appropriate to choose PE (polyethylene) coating; if environmental protection is a priority, PLA (polylactic acid) coating is a biodegradable option, but it is suitable for cold drinks.

3. Raw Material Ratio

In the production process of paper cups, the ratio of paper cup fan and base paper is crucial to ensure production efficiency and product quality. Usually, every 4-5 tons of paper cup fan (the main part of the paper cup) needs to be matched with 1 ton of base paper (used to make the bottom of the paper cup). The paper cup fan is responsible for forming the cup wall of the paper cup. Its thickness and quality directly affect the durability and thermal insulation performance of the paper cup, while the base paper increases the strength and support of the bottom of the paper cup to ensure that the paper cup does not leak or deform during use. Through this reasonable ratio, we can effectively avoid material waste and optimize production efficiency, while ensuring the structural stability and functionality of each paper cup.

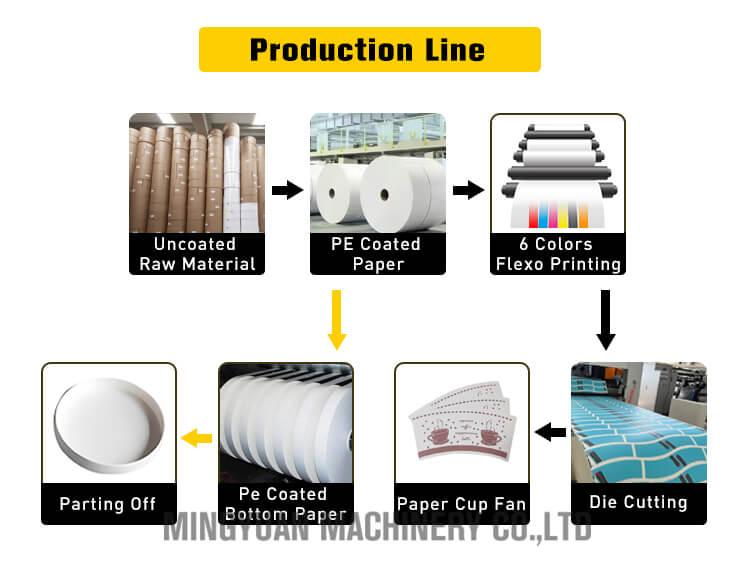

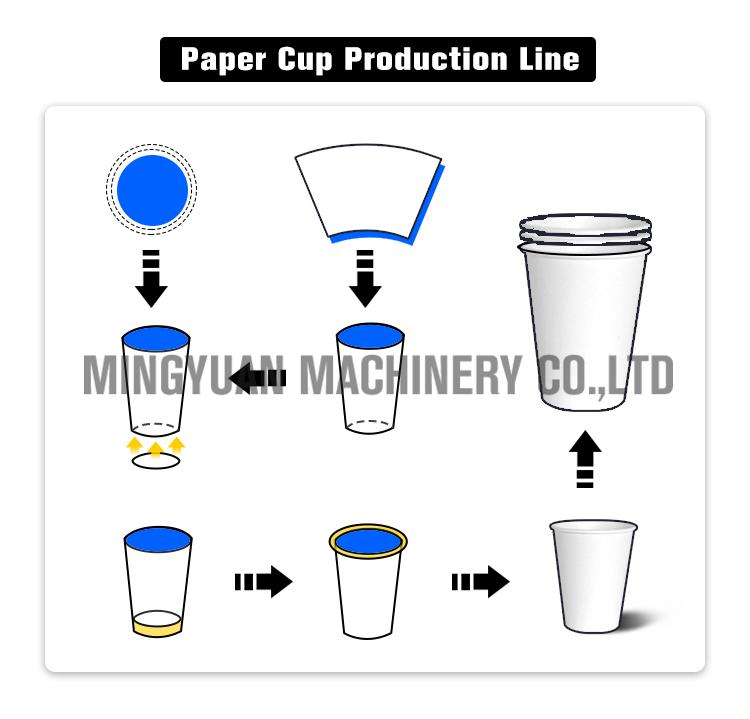

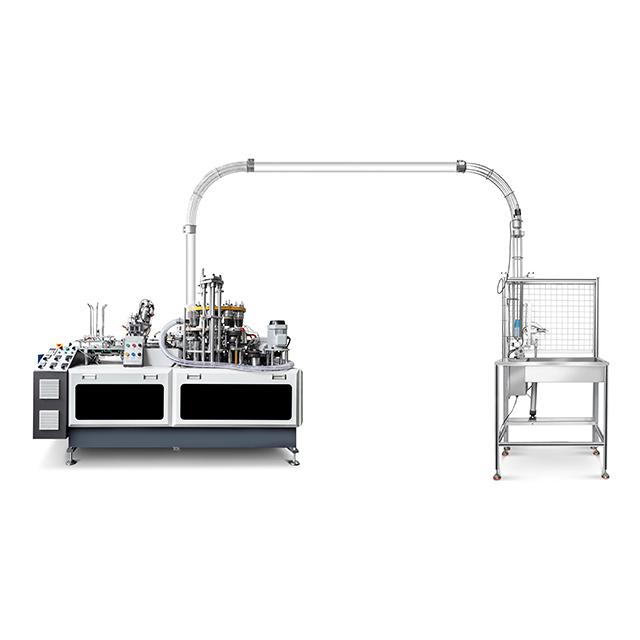

4. Raw Material Production Line

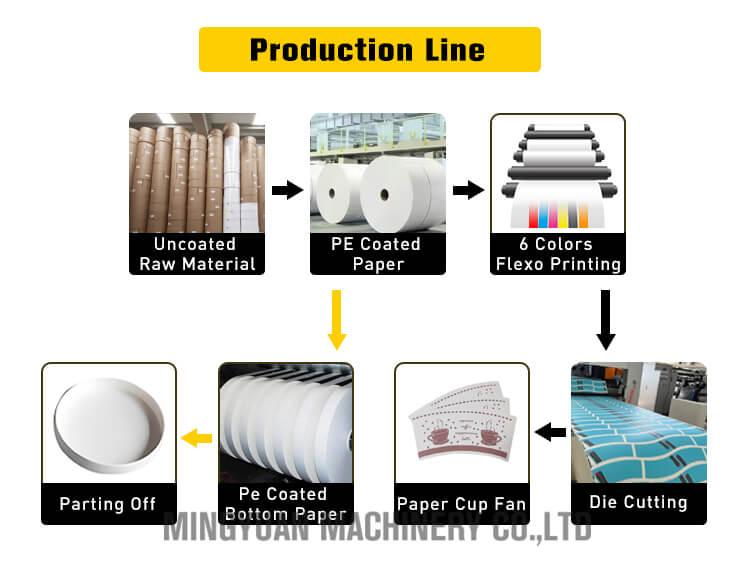

In the production of paper cups, the production process of paper cup fans and base paper includes key steps. The production of paper cup fans starts with the selection of food-grade paper, coating (such as PE or PLA coating), printing design (supporting multi-color printing).

The production of base paper includes selecting base paper of appropriate thickness, coating (such as PE or PLA coating), precise cutting and die pressing in the paper cup machine to form the bottom of the paper cup.

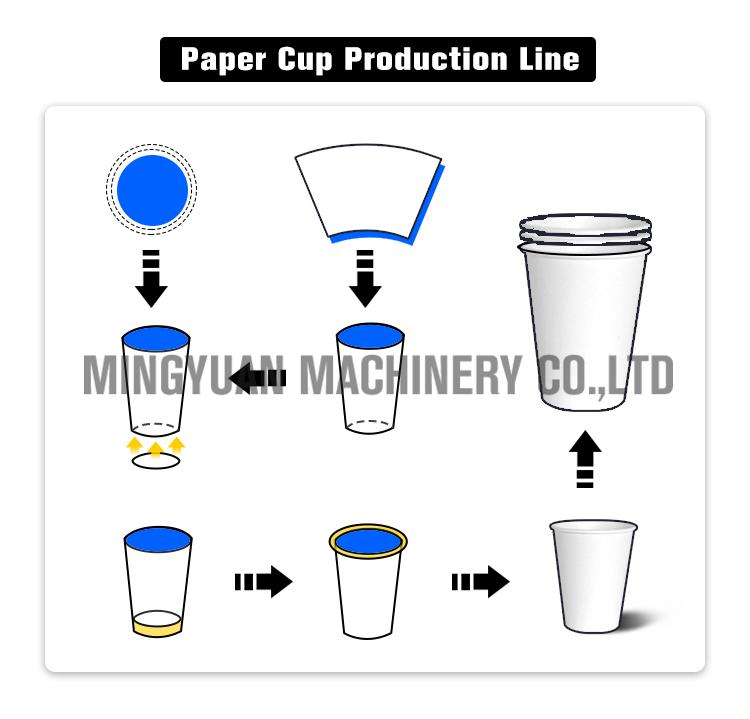

Finally, the paper cup machine assembles and forms the paper cup fans with the base paper (folding, gluing and curling). The paper cup machine undergoes strict quality inspection and adjustment to ensure the structural stability and functionality of the paper cup. This process ensures that the paper cup meets the design standards and achieves efficient production.

5. Our Advantages

1. Food grade material

Our paper fans are made of food grade raw materials, with weights ranging from 150gsm to 350gsm, and can be selected with single or double PE coating. Whether it is the cardboard, PE coating or the water-based ink used, all materials meet food grade standards.

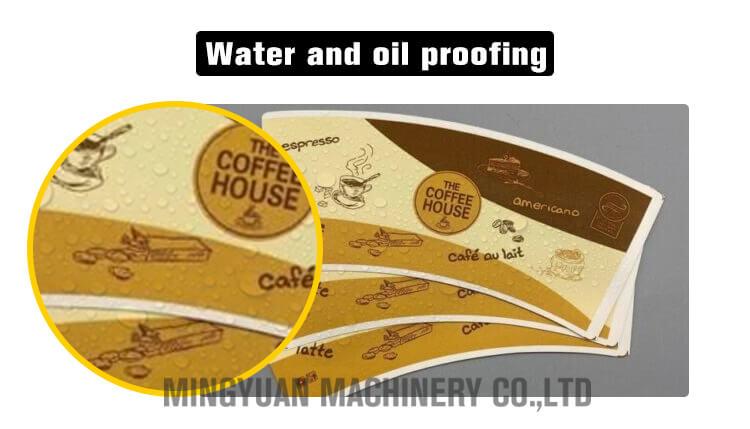

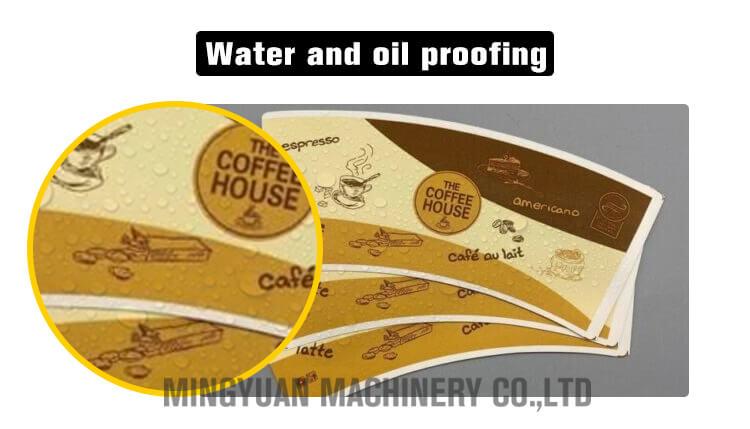

2. Waterproof and oil-proof

Our paper cups use advanced coating technology, such as PE (polyethylene) or PLA (polylactic acid), to effectively improve the water-proof and oil-proof performance of paper cups. These coating materials can prevent liquid penetration and grease leakage, maintain the integrity of the paper cup, and avoid leakage or spillage of drinks during use.

3. Anti-leakage

Our paper cup machine uses bottom knurling technology to ensure the anti-leakage performance of paper cups. This technology effectively improves the sealing of the bottom of the paper cup by forming tiny patterns on the bottom of the paper cup, preventing liquid leakage without the use of additional adhesives. This process enhances the overall structural stability and durability of the paper cup, providing a more reliable anti-leakage effect.

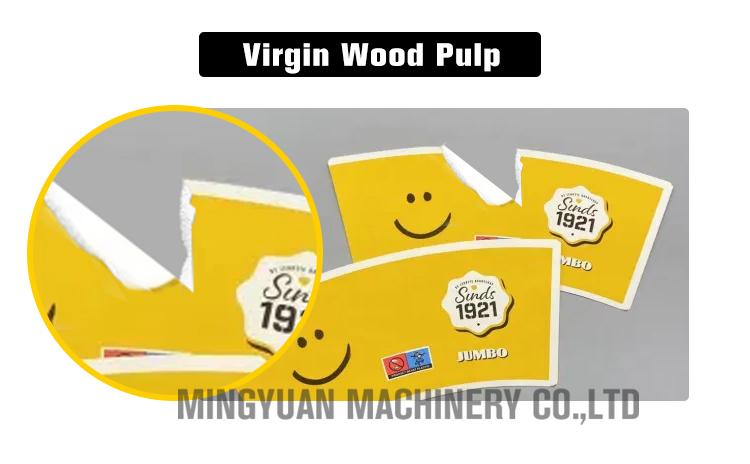

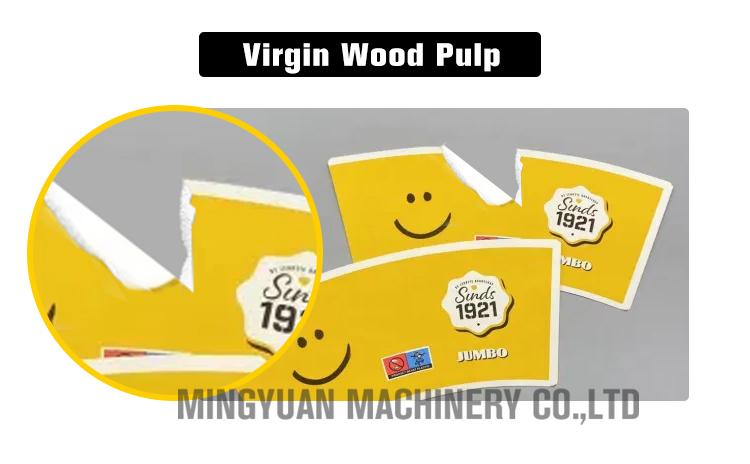

4. Virgin wood pulp

We use virgin wood pulp as the base raw material for paper cups to ensure the strength and durability of paper cups. Virgin wood pulp not only has good paper quality and stability, but also makes paper cups more environmentally friendly. The use of wood pulp reduces the dependence on recycled paper, while improving the overall structural strength of paper cups, making them perform well in various usage scenarios.

Through these advantages, we not only ensure the high quality and safety of paper cups, but also improve the practicality and environmental protection performance of paper cups to meet the needs of different customers.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China