In the paper cup production process, choosing the right paper cup machine is crucial for production efficiency, product quality and ease of operation. Single turnplate paper cup machine and double turnplate paper cup machine are two common types of paper cup machines, each with unique features and advantages. Understanding the main differences between them will help you find the most suitable equipment.

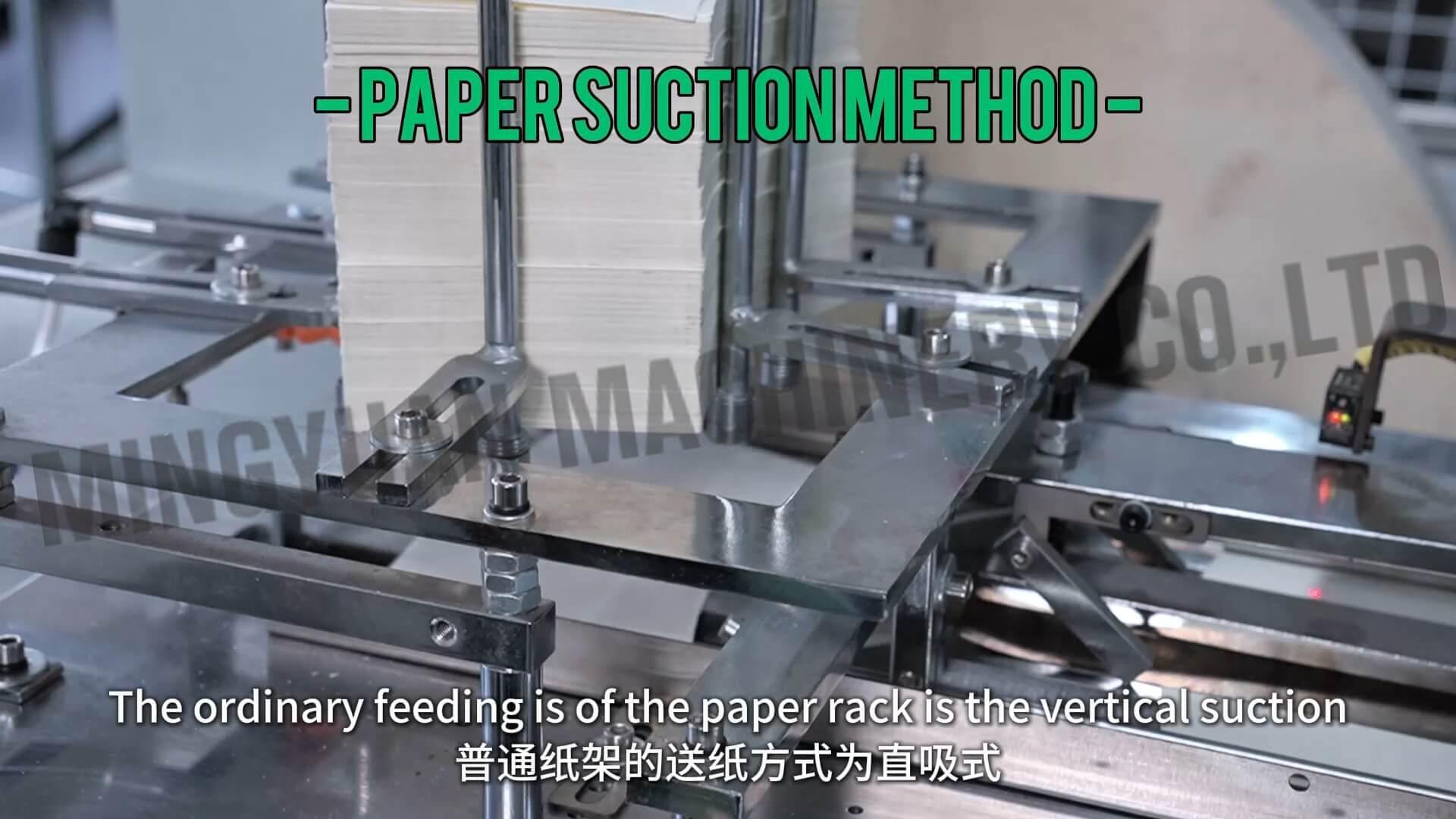

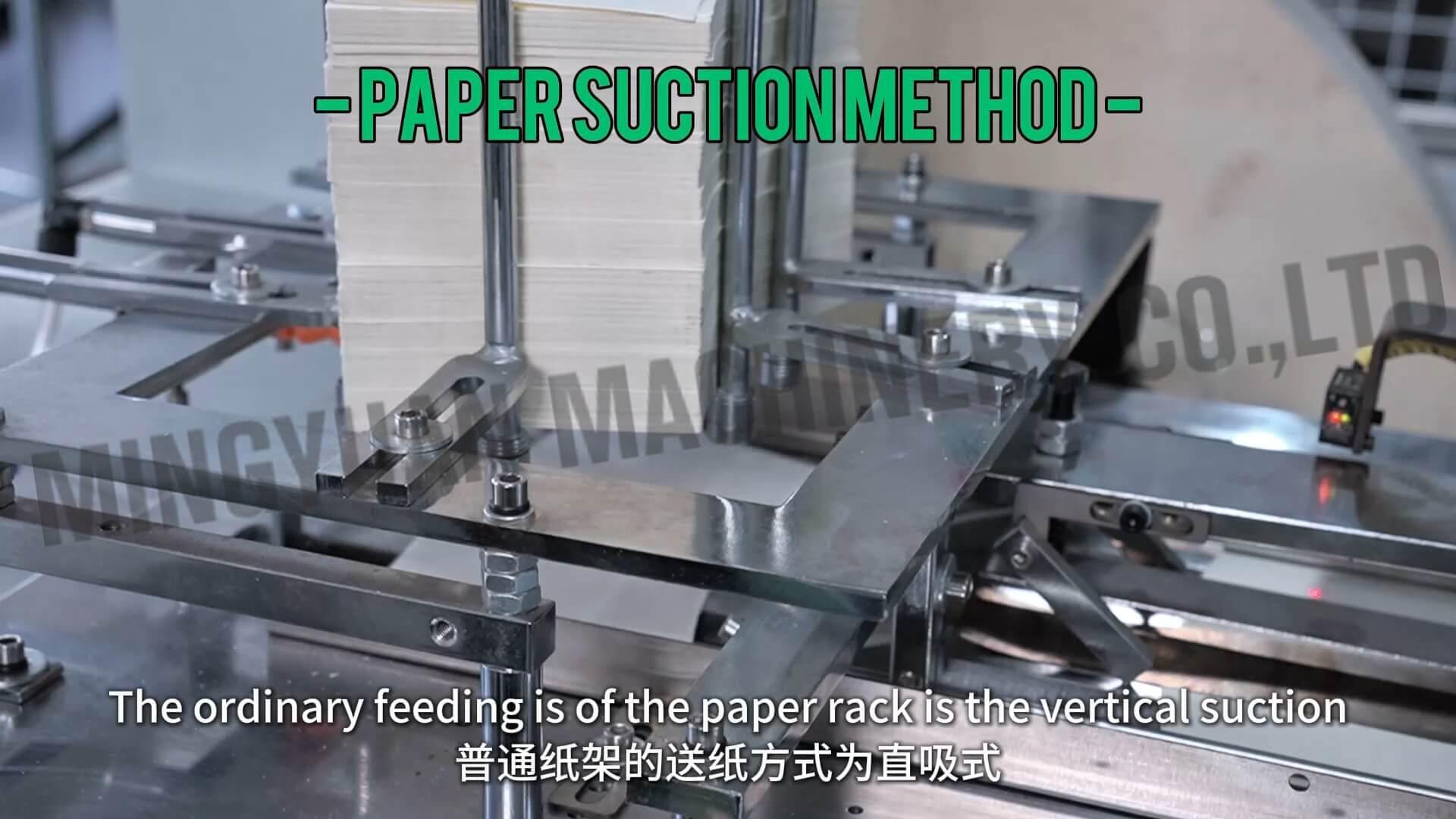

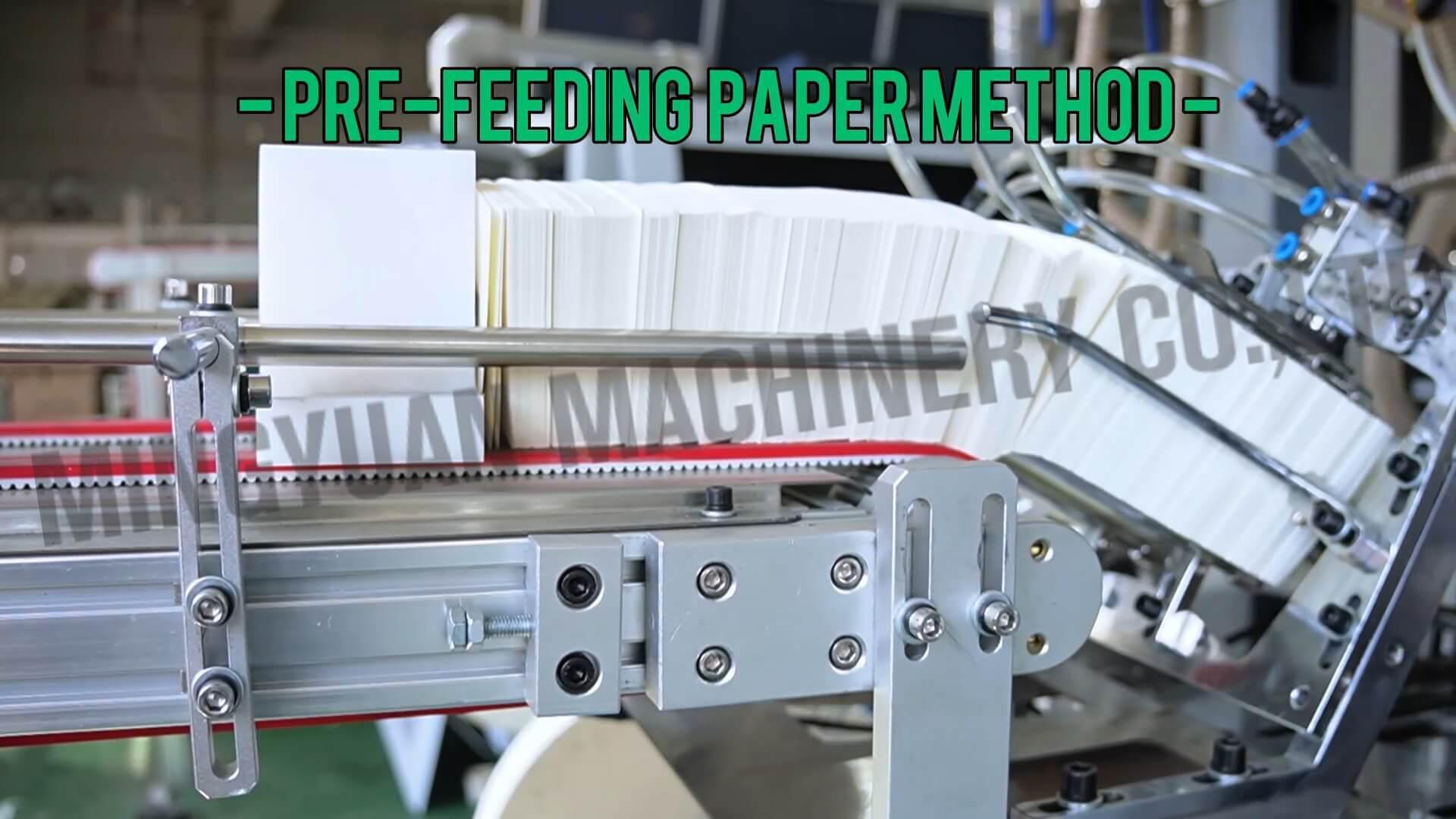

1. Differences in paper feeding systems

Single turnplate machine:

Single turnplate machines usually use direct suction paper feeding, and the paper fan is delivered to the production line through a paper press. However, this method is prone to paper jams, affecting production stability. Since all processes are concentrated on one turnplate, any problem in any link may affect the entire production process.

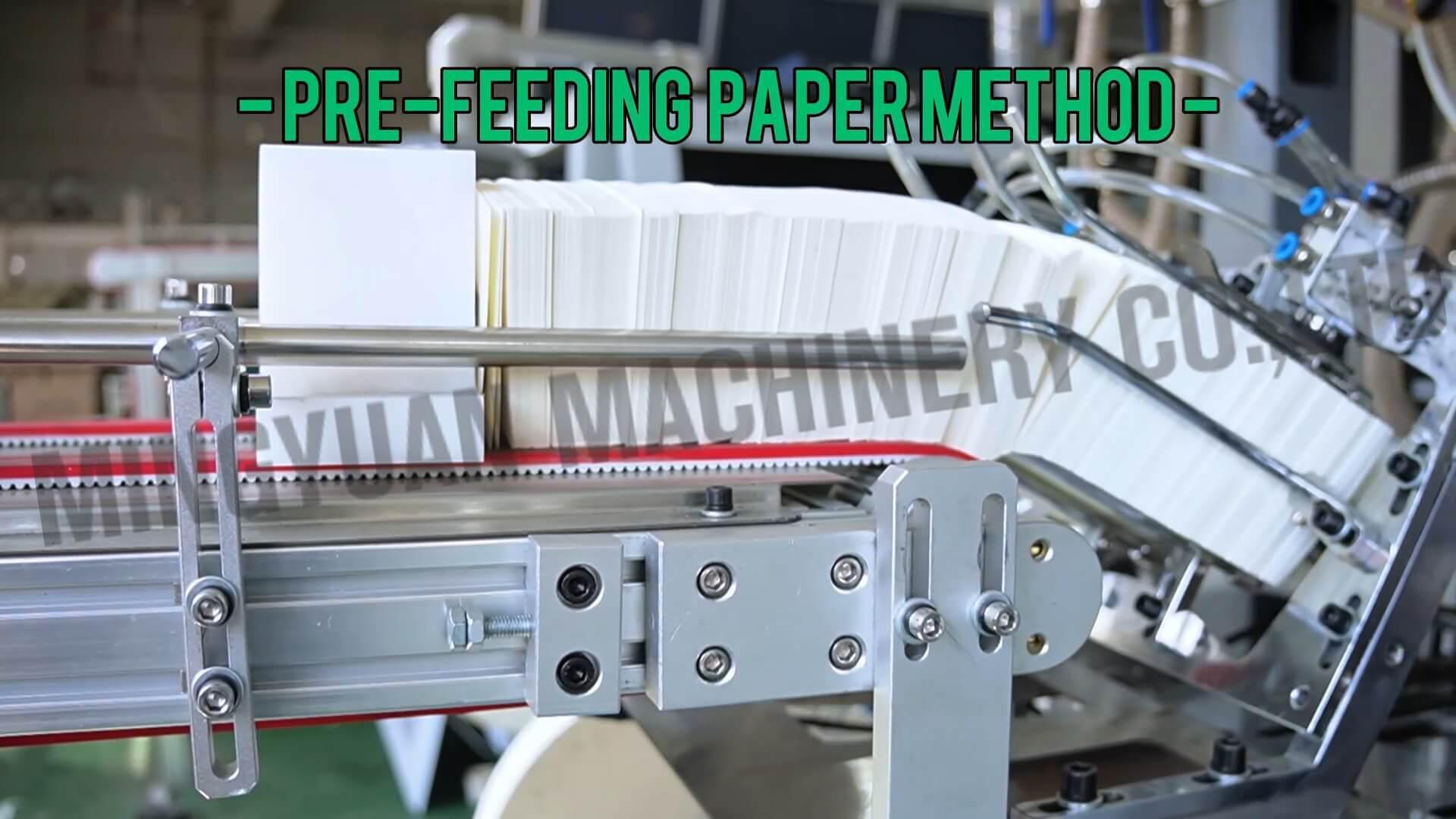

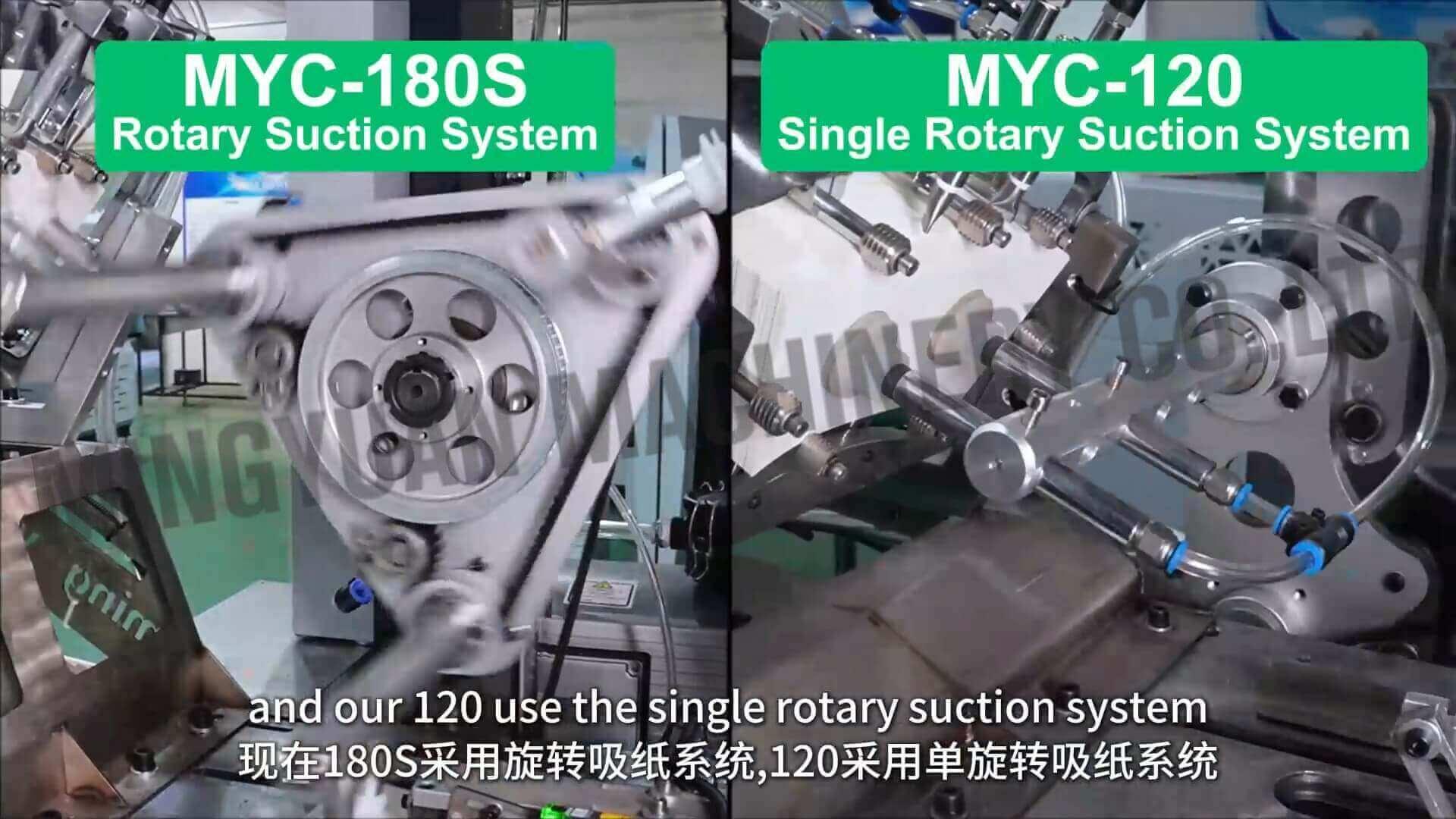

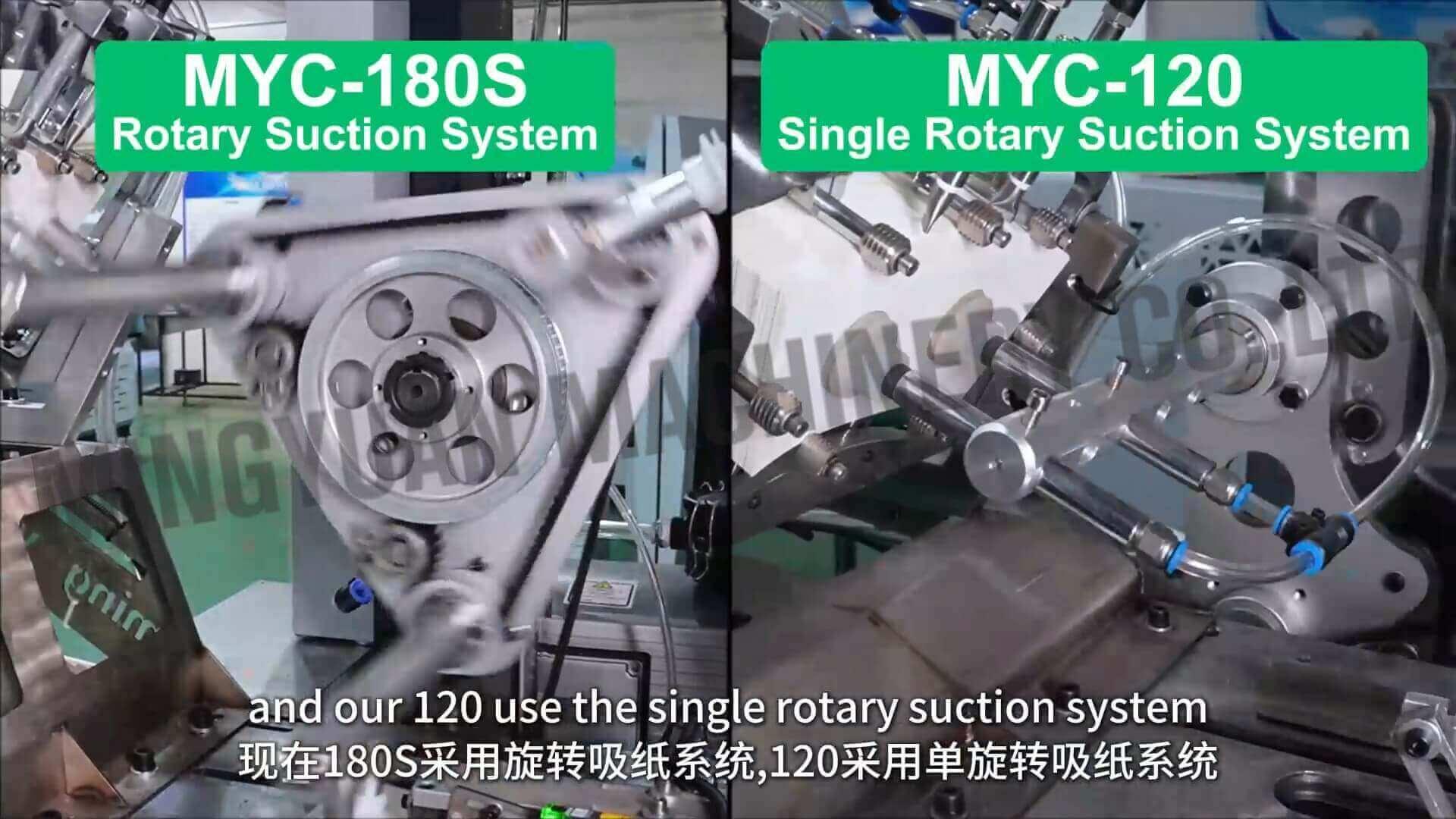

Double turnplate machine:

Our double turnplate machines, such as MYC-120 and MYC-180S, are equipped with an advanced pre-feeding system, which has a higher degree of automation and avoids the defects of manual paper feeding. This not only improves production efficiency, but also effectively saves labor costs. The MYC-120 uses a single rotary paper suction system, while the MYC-180S is further upgraded to a rotary paper suction system, which can directly deliver the paper fan to the runway, significantly reducing paper jam problems and ensuring a smooth paper feeding process.

2. Upgrade of heating system

Single turnplate machine:

Single turnplate machines are usually equipped with two air-blowing furnaces for heating. This heating method is relatively simple, the heating speed is slow, and the temperature control is not precise enough, which may affect the molding quality of paper cups.

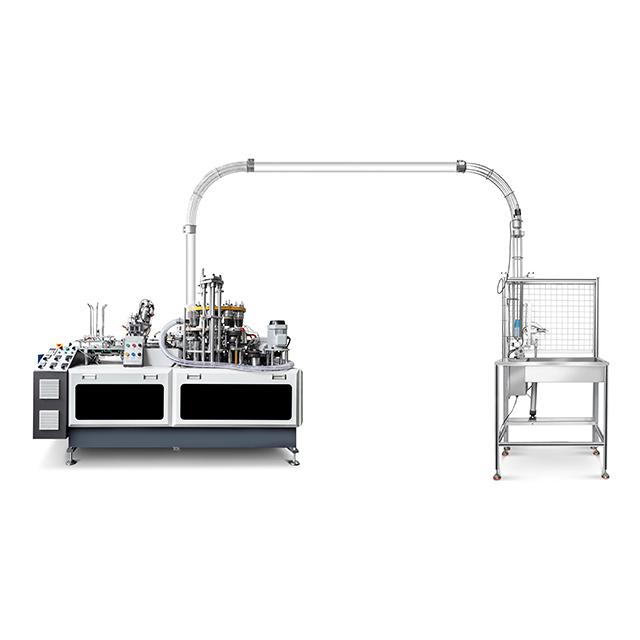

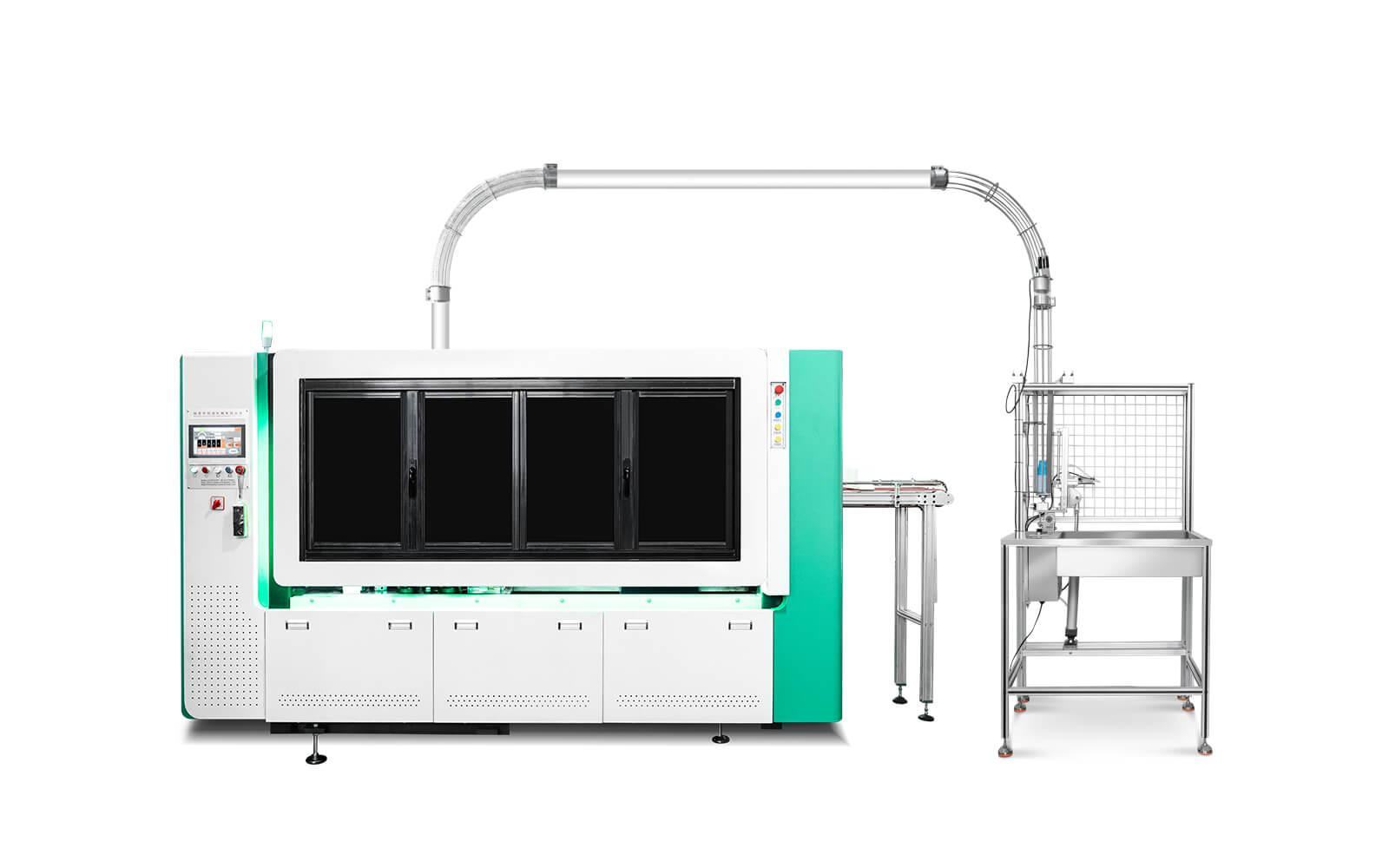

Double turnplate machine:

Our company's double turnplate machine is equipped with a hot air gun system, which provides fast and continuous heating, rapid temperature rise and small temperature difference, thus significantly improving production speed and paper cup forming quality.

Compared with the single turnplate machine, the double turnplate machine has obvious advantages in the heating system. MYC-120 is equipped with 4 hot air guns: 1 for preheating the paper feeding, 2 for bottom sealing, and 1 for the knurling process.

The upgraded MYC-180S is equipped with 5 hot air guns, 2 of which are used for preheating the paper feed, heating the upper and lower layers of the paper fan respectively to increase the flexibility of the paper, and the remaining 3 are used for bottom sealing and knurling processes, effectively reducing the time the paper cups stay in the machine.

3. Optimization of curling process

Single turnplate machine:

In a single turnplate machine, the curling process is usually performed only once, and all operations are completed on one turnplate. This single-time curling method is relatively simple, but it may not achieve higher aesthetics and fineness.

Double turnplate machine:

The double turnplate machine has significant advantages in the curling process. Both MYC-120 and MYC-180S are equipped with a dedicated turntable for curling, capable of performing two curling processes. This double-time curling not only improves the aesthetics of the cup mouth, but also increases the strength and durability of the paper cup, ensuring uniform quality of the finished product.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China