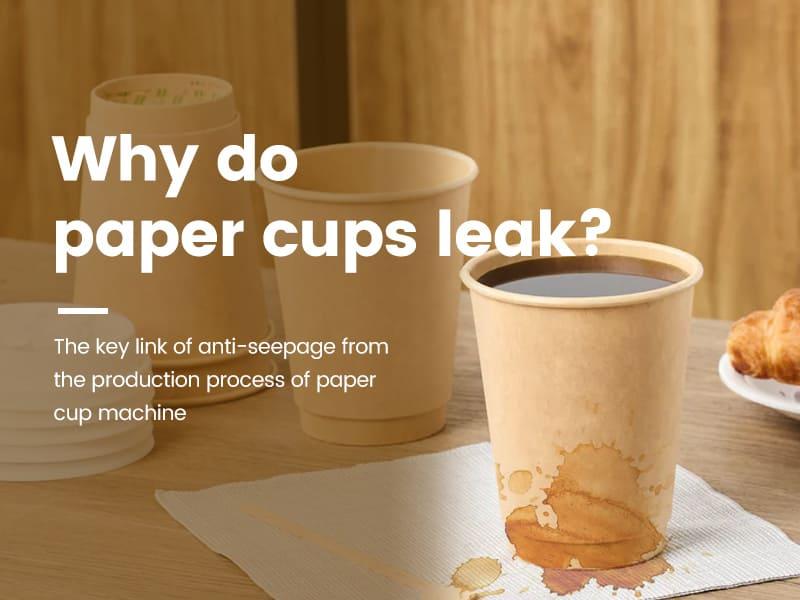

Why Do Paper Cups Leak? — Understanding the Key Stages of Leak Prevention in Paper Cup Machine Production

Paper cups may look simple, but every detail in their production is closely related to leak prevention.

Especially for beverage cups, even a slight leakage not only affects user experience but also reveals issues in the production process or equipment adjustment.

So, why do paper cups leak — and where should we start to solve the problem?

1. Common Causes of Paper Cup Leakage

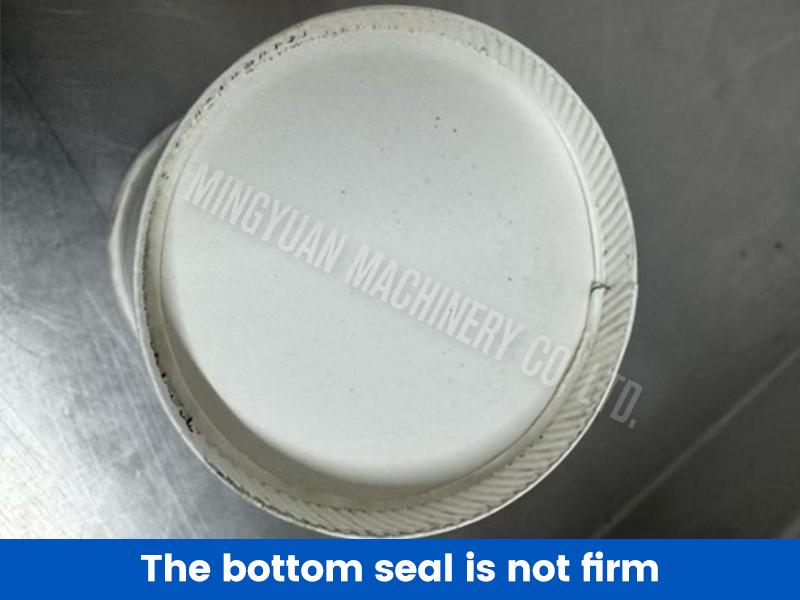

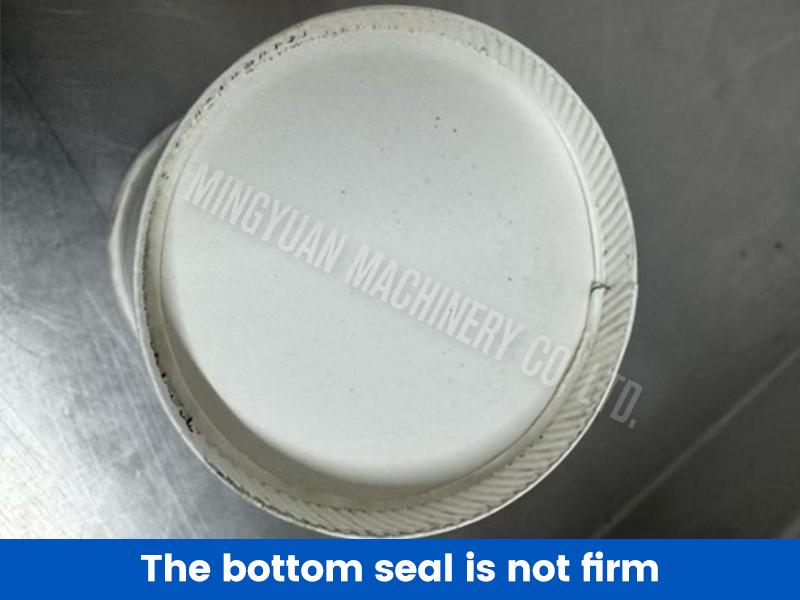

1.1 Bottom Sealing Failure

The bottom of a paper cup is sealed through heating and pressing.

If the temperature is insufficient, the bottom folding is uneven, knurling pressure is too low, or the paper thickness does not match the settings, the bottom may not bond completely.

Once liquid enters the gap, leakage occurs along the seam.

1.2 Uneven Bottom Folding

When the bottom fold is too deep or one side is deeper than the other, heat cannot be evenly distributed inside.

As a result, the PE coating fails to melt properly and cannot bond, causing potential leakage.

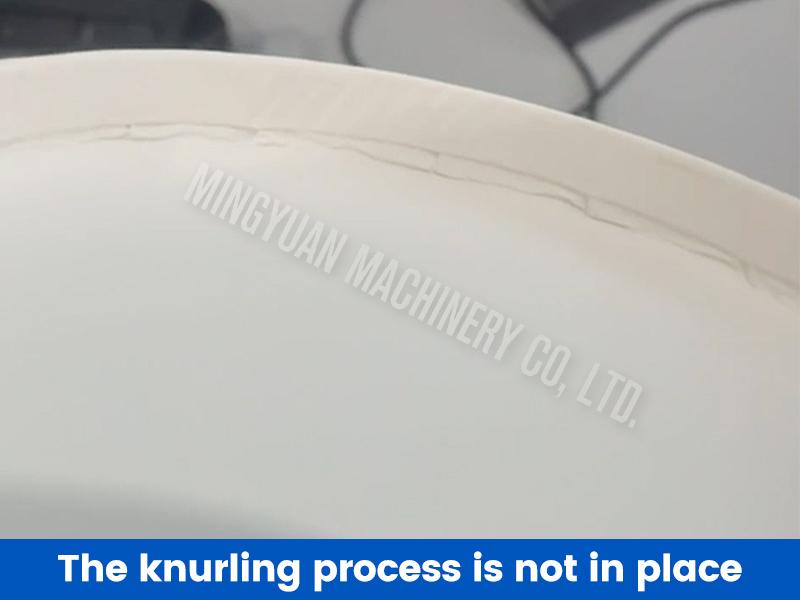

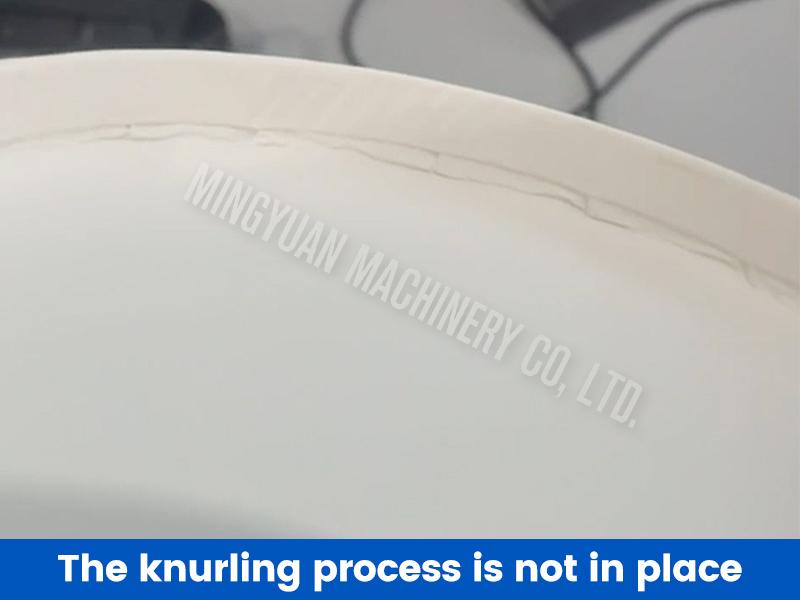

1.3 Incomplete Knurling Process

Knurling is the key process for preventing leakage.

Through high-temperature compression, the paper cup machine allows the cup bottom and sidewall to interlock with multiple folded layers — forming a strong waterproof seal.

If the knurling depth is insufficient or the alignment is off, sealing performance will drop significantly.

1.4 Poor PE Coating Quality

The surface of cup paper is usually laminated with PE coating (single or double layer) to prevent liquid from soaking into the paper fibers.

If the coating is uneven, peeled, or damaged, even precise sealing cannot fully prevent leakage.

1.5 Material and Temperature Mismatch

Different paper weights and coating thicknesses require corresponding heating times and temperatures.

If the paper cup machine parameters are not properly set, it may cause either weak bonding or overheating, both of which lead to leakage.

2. The Key Role of Paper Cup Machines in Leak-Proof Production

2.1 Precise Heating System

Modern paper cup machines (such as the MYC Series from Mingyuan Machinery) use ultrasonic heating, which provides stable and uniform temperature.

This ensures that the PE film melts completely, greatly improving the sealing strength of the cup.

2.2 High-Precision Knurling Molds

The knurling structure directly determines the leak-proof performance of the cup bottom.

Upgraded molds have thicker metal components and enhanced vacuum suction, allowing the bottom to fit tightly and form a clear, deep knurling pattern.

2.3 Automatic Detection and Correction System

Intelligent paper cup machines can monitor paper position, sealing pressure, and other key parameters in real time.

When abnormalities occur, the machine automatically alarms or stops operation, preventing large-scale defects.

2.4 Stable Paper Feeding and Positioning System

If the paper is not correctly positioned before forming, the overlap between the cup body and bottom may shift, causing the sealing line to misalign.

The latest pre-feeding structure effectively reduces deviation and ensures precise forming.

3. Practical Tips to Improve Leak-Proof Performance

3.1 Use food-grade virgin pulp paper and high-quality PE coating.

Uniform paper fibers help achieve consistent heat sealing.

3.2 Regularly maintain molds and heating systems.

Ensure accurate temperature control and clean molds without residue.

3.3 Control humidity and paper storage conditions.

Moist paper can lead to unstable sealing results.

3.4 Perform leak-proof tests before mass production.

Conduct water or pressure tests to ensure every finished cup is leak-proof.

4. Conclusion

At first glance, paper cup leakage may seem like a paper issue — but in fact, it is a matter of process and equipment coordination.

A high-performance paper cup machine, equipped with a stable heating system, precise knurling molds, and automatic detection features, is the foundation of a well-sealed, durable, and leak-proof paper cup.

Only a stable machine can produce truly leak-proof cups.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China