—Key details that are easily overlooked in paper cup production

I. Stable Raw Materials: The Best Protection for Your Machine

In paper cup production, the problem is often not "the machine is broken," but rather fluctuations in raw material quality causing abnormal machine operation.

Common but easily overlooked issues include:

Excessive fluctuations in paper weight, leading to frequent adjustments in forming pressure

Unstable coating thickness, affecting the consistency of bottom sealing and rim curling

Inconsistent paper fan cutting precision, increasing mold impact and uneven wear

These problems directly result in:

Uneven mold stress

Repeated compensation by the forming mechanism

Accelerated wear on critical components

In the long run, stable paper quality essentially extends the mechanical life of the paper cup machine.

II. Reasonable Operating Speed is More Important Than "Maximum Speed"

Many factories, after completing commissioning, attempt to operate paper cup machines near their speed limits.

In the short term, output does increase;

In the long term, this often leads to three problems:

A significant increase in the frequency of mechanical impacts

Reduced margins for errors in heating, sealing, and knurling processes

Small errors are more easily amplified into malfunctions

A more reasonable approach is to:

Choose a long-term stable operating speed

Retain safety margins for the mechanical structure and heating system

Evaluate efficiency using "stable hourly output" rather than "instantaneous maximum speed"

For paper cup machines,

stability is more important than speed.

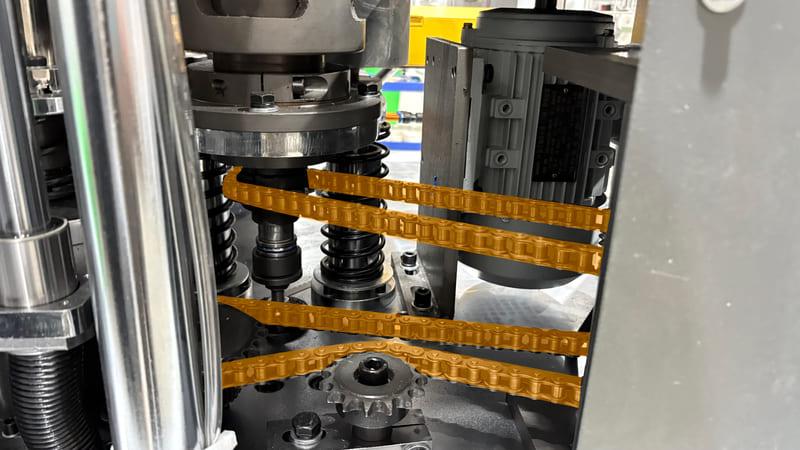

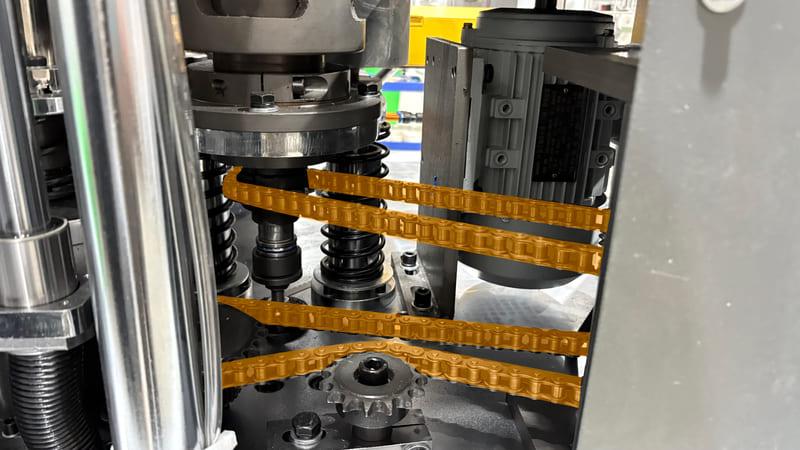

III. Lubrication and Cleaning: The Most Easily Underestimated Maintenance Actions

In the daily maintenance of paper cup machines, lubrication and cleaning are often considered "basic operations" and are easily overlooked.

However, in reality:

Whether bearings, slide rails, and transmission parts are properly lubricated;

whether paper scraps, glue residue, and coating residue are cleaned up in a timely manner;

whether there is long-term carbon buildup or impurities around heating components

will directly affect:

Transmission resistance;

Temperature stability;

The wear rate of critical components.

It is recommended to establish a fixed maintenance schedule, rather than waiting for abnormalities to occur before addressing them.

IV. Standardized Operation is More Important Than Frequent Repairs

Many paper cup machine malfunctions do not originate from the parts themselves, but from improper operation, such as:

Improper mold installation or forced tightening;

drastic and repeated parameter modifications;

ignoring abnormal sounds or slight deviations.

In the long run, a single instance of improper operation can shorten the equipment's lifespan by several months.

Establishing clear operating procedures and assigning responsibilities is a crucial step in protecting the lifespan of the paper cup machine.

V. Regularly Inspect Key Components to Prevent Small Problems from Becoming Major Failures

It is recommended to focus on periodic inspections of the following areas:

The tightness of the mold and connecting parts

The stability of the heating system

The alignment accuracy of the molding station

Whether there are leaks in the vacuum and pneumatic systems

Many serious failures initially stem from a

small, controllable deviation.

The significance of regular inspections lies in resolving problems in their early stages.

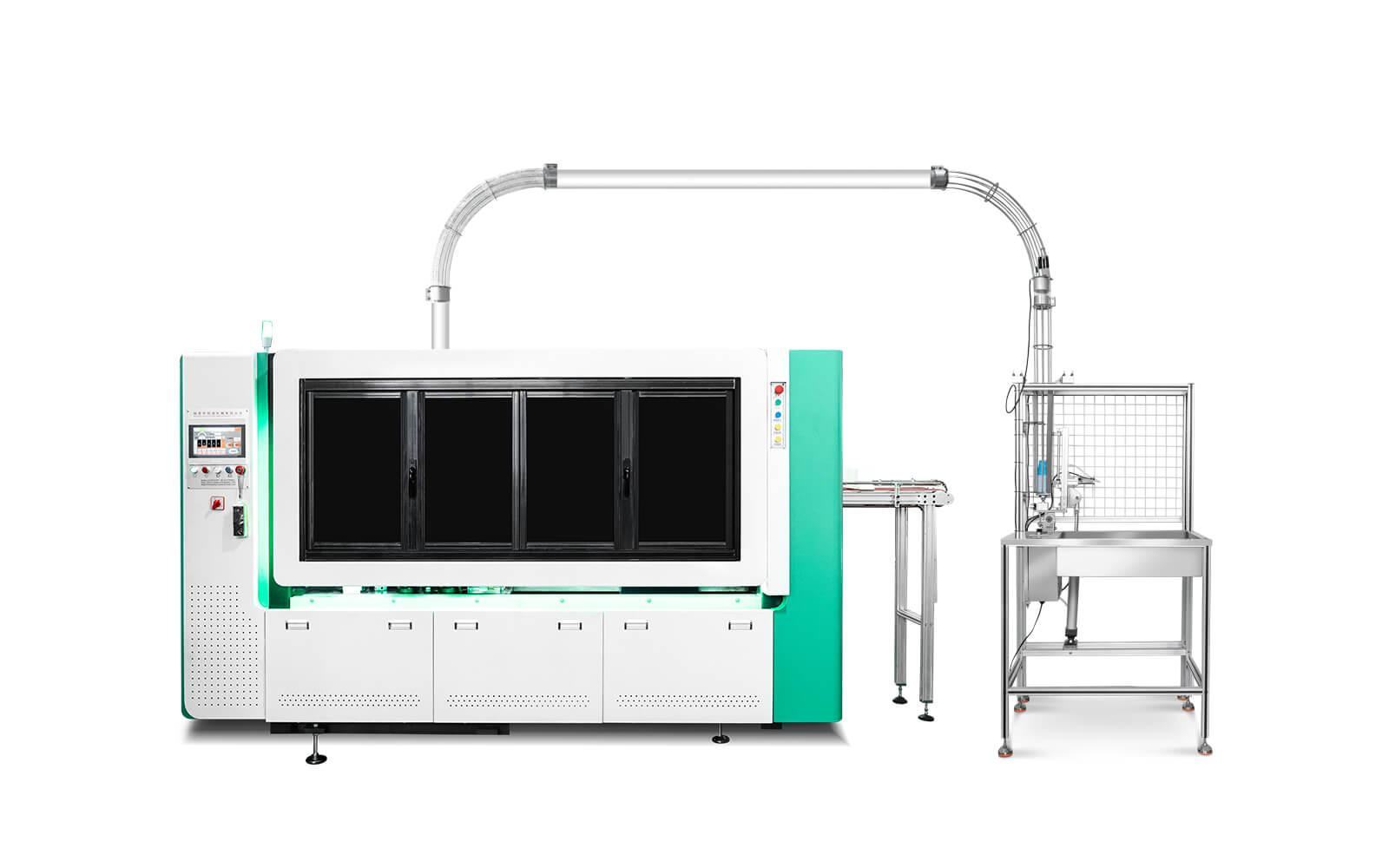

Conclusion: The lifespan of a paper cup machine is determined by its usage.

A paper cup machine is not a one-time consumable device, but rather a long-term investment.

What truly determines its lifespan is not just configuration parameters, but rather:

Whether the model is selected appropriately

Whether it matches the raw materials

Whether it operates stably over a long period

Whether it is operated and maintained according to regulations.

From a production perspective, extending the lifespan of a paper cup machine essentially reduces the long-term manufacturing cost per unit of paper cup.

If a paper cup machine is used correctly, it often delivers stability and reliability far exceeding expectations.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China