Installation Guide for Paper Cup and Paper Plate Making Machine

Introduction

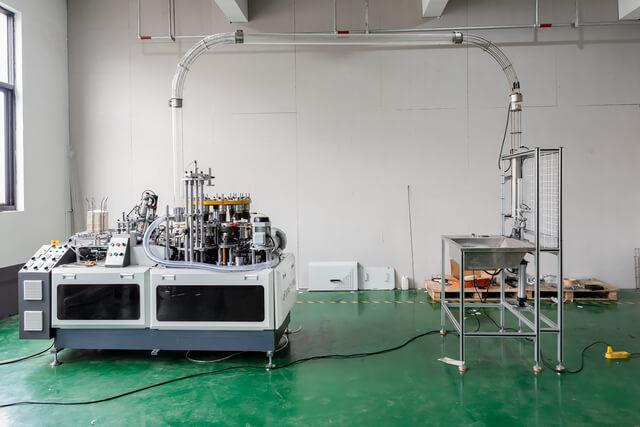

Setting up a paper cup and paper plate making machine is an essential step in starting your own business in the disposable tableware industry. Proper installation ensures the smooth operation and efficiency of the machine, ultimately contributing to the success of your business. This installation guide will walk you through the necessary steps to set up your paper cup and paper plate making machine correctly.

Step 1: Unpacking and Inspection

Before starting the installation process, carefully unpack the machine and inspect it for any signs of damage during shipping. Make sure all components are included as per the packing list provided by the manufacturer. Any missing or damaged parts should be reported to the supplier immediately for replacement.

Step 2: Location Selection

Choose a suitable location for installing the machine, ensuring adequate space for operation and maintenance. The site should have a stable power supply, proper ventilation, and a level surface to place the machine securely. Additionally, consider proximity to raw materials and finished goods storage areas for convenience.

Step 3: Machine Assembly

Follow the instruction manual provided by the manufacturer to assemble the various components of the paper cup and paper plate making machine. Pay close attention to the sequence of assembly and ensure that each part is securely connected. Tighten all bolts and screws properly to prevent any loose fittings during operation.

Step 4: Electrical Connection

Hire a qualified electrician to connect the machine to the power supply following the electrical specifications provided by the manufacturer. Ensure proper grounding to prevent electrical hazards. Test the machine's electrical components to verify that all functions are working correctly before proceeding to the next step.

Step 5: Machine Calibration

Calibrate the machine settings as per the product requirements specified by the manufacturer. Adjust parameters such as temperature, pressure, and speed to achieve the desired output quality of paper cups and plates. Conduct trial runs to fine-tune the settings and make necessary adjustments for optimal performance.

Step 6: Safety Precautions

Prioritize safety by implementing necessary precautions such as installing safety guards, emergency stop buttons, and warning signs around the machine. Provide adequate training to operators on safe machine operation, maintenance procedures, and emergency protocols. Regularly inspect and maintain the machine to ensure safe and efficient operation.

Step 7: Test Run

Before starting full production, conduct a test run of the machine to check its functionality and performance. Produce a small batch of paper cups and plates to evaluate the quality and consistency of the products. Inspect for any defects or issues during the production process and make adjustments as needed.

Conclusion

Successfully installing a paper cup and paper plate making machine requires careful planning, attention to detail, and adherence to safety guidelines. By following this installation guide and working closely with the manufacturer, you can set up your machine efficiently and start producing high-quality disposable tableware for your business. Remember to prioritize maintenance and regular inspections to ensure the long-term reliability of your machine.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China