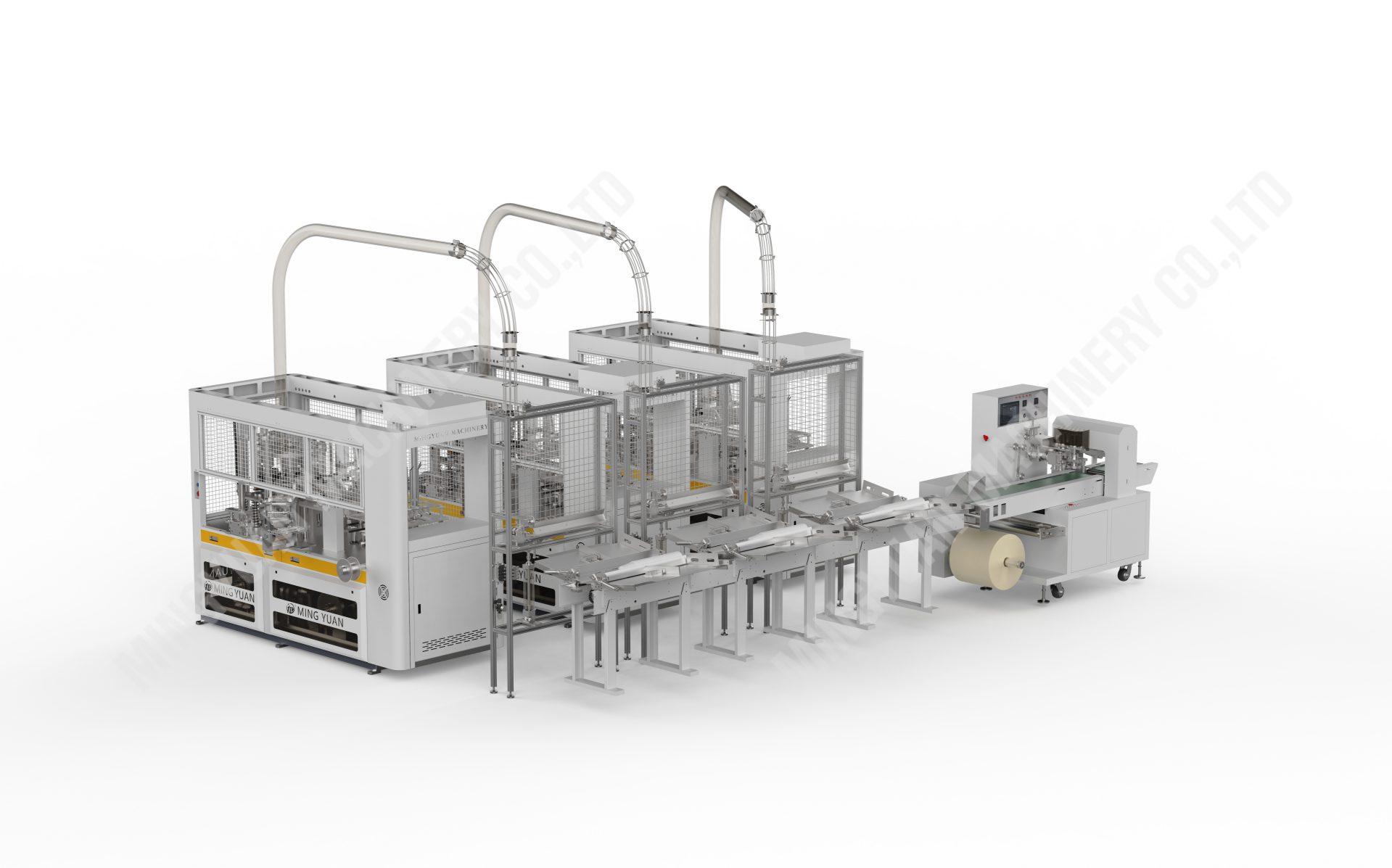

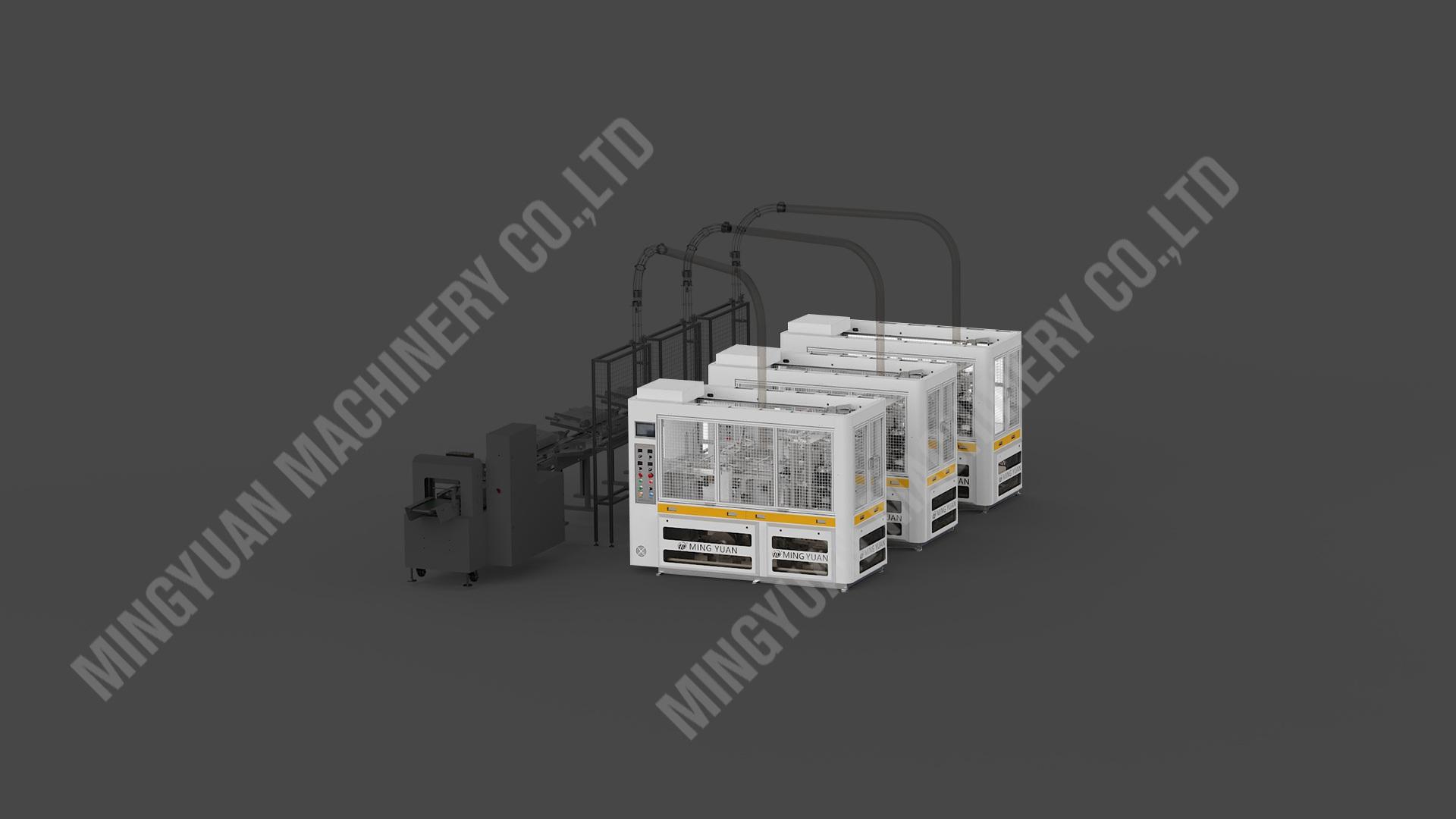

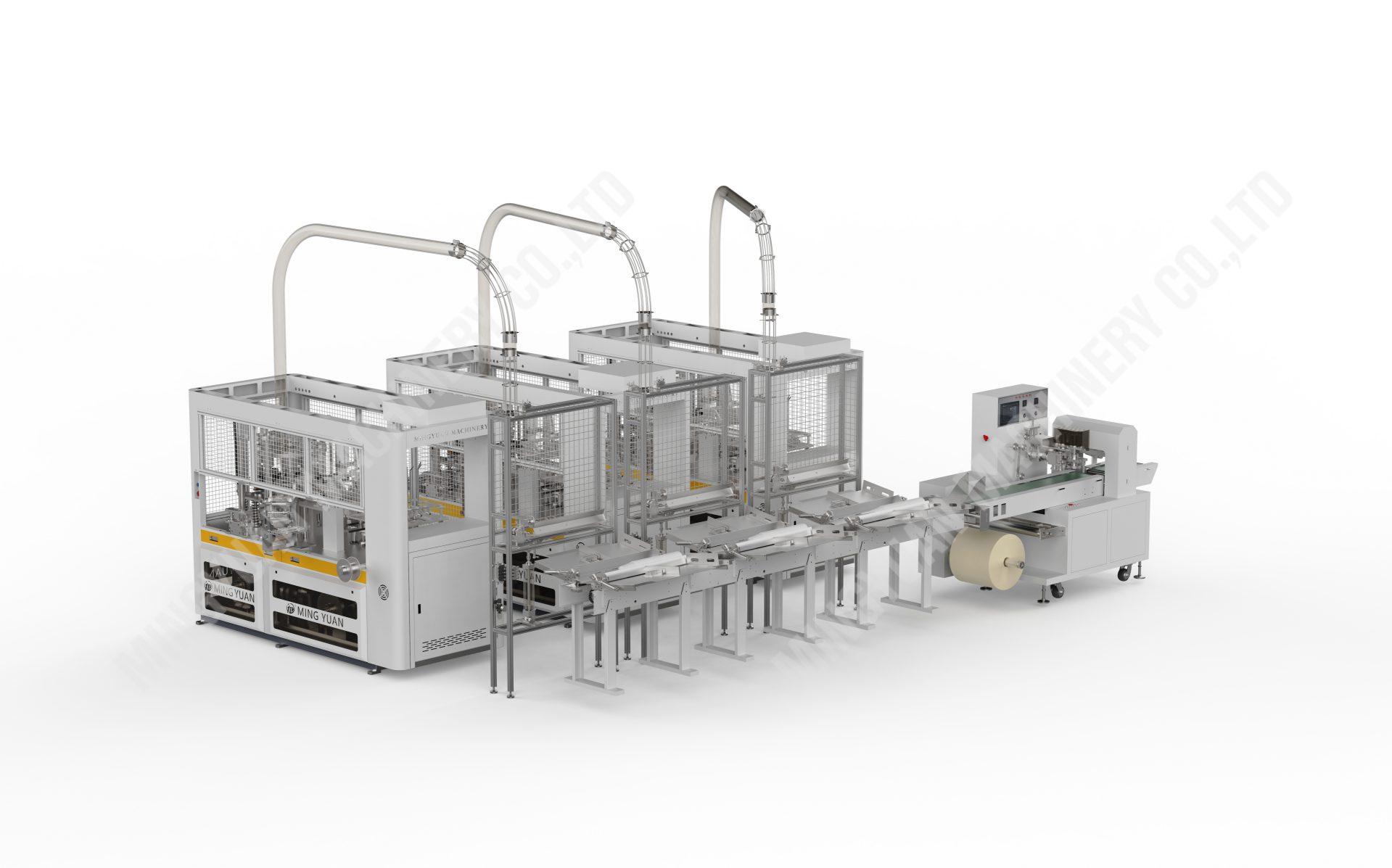

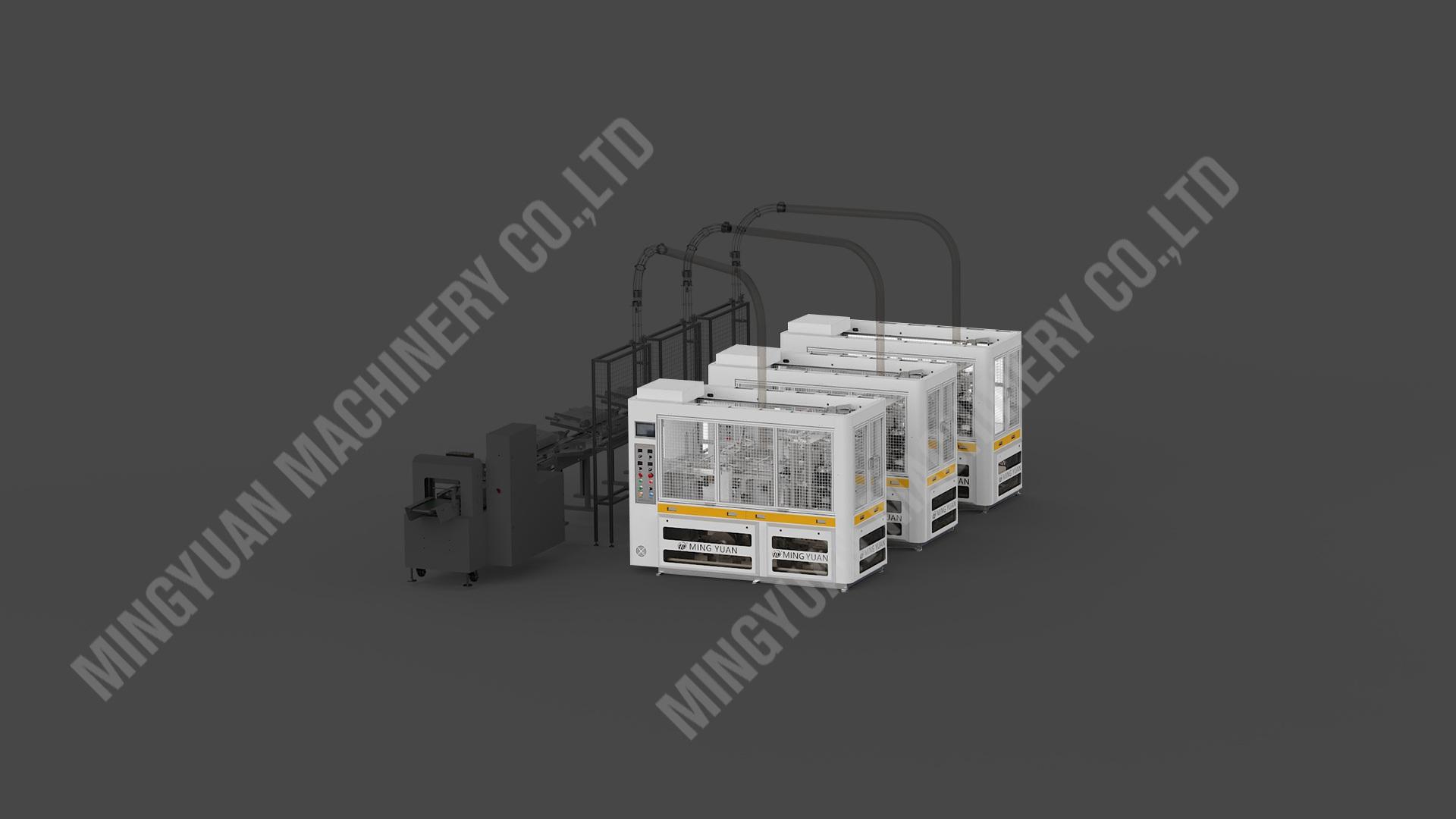

1.Three Machines, Three Sizes:OCM12 High-end Paper Cup Machine*3 + 450X Paper Cup packaging Machine

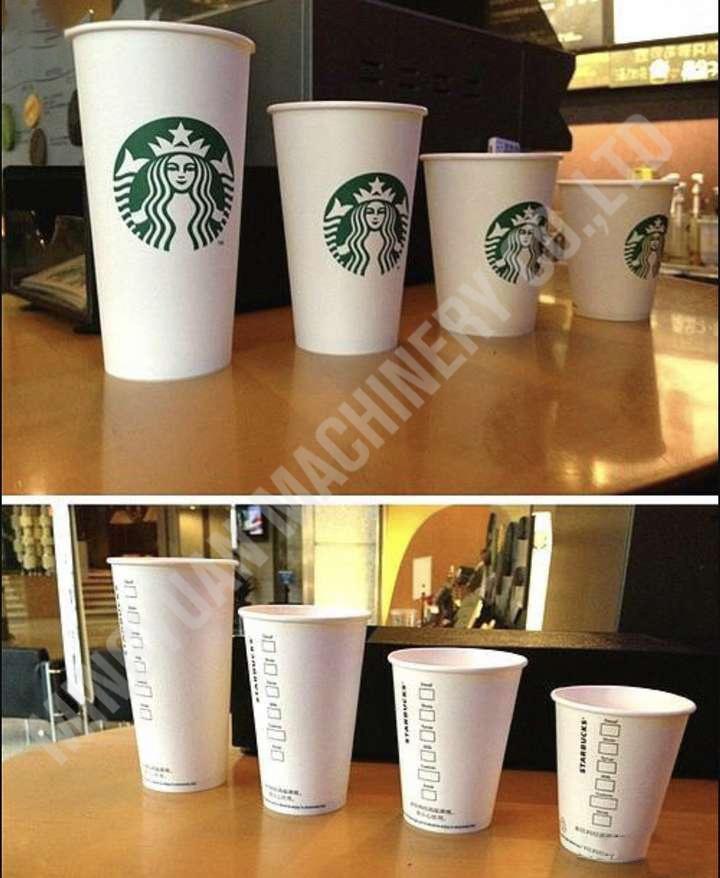

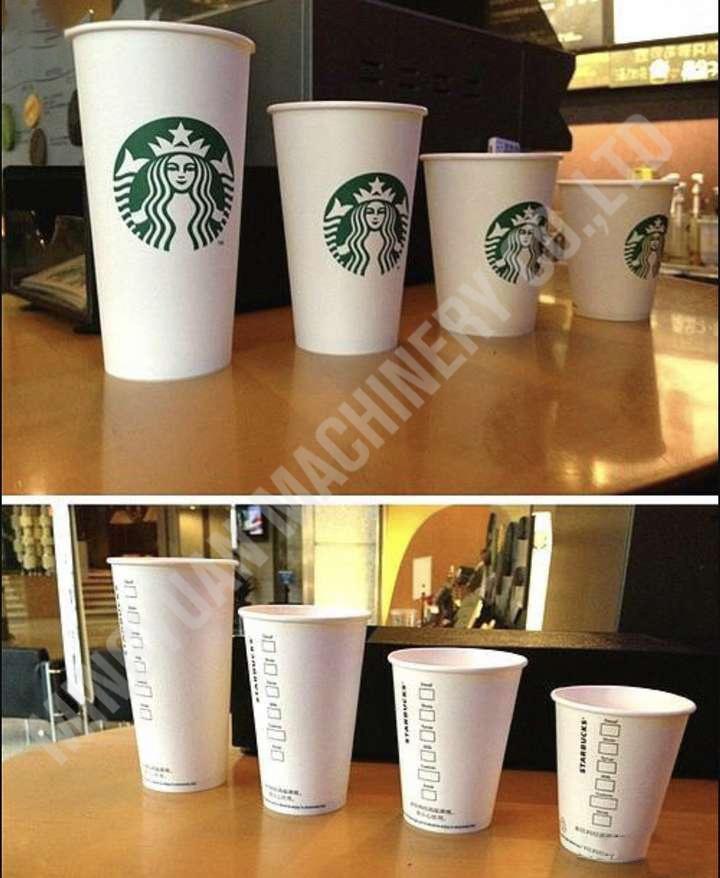

The production line consists of three OCM12 high-end paper cup machines, each producing a different cup size simultaneously (e.g., 8oz, 12oz, 16oz). No mold change, no downtime. All cups are transferred to a 450X rotary knife packaging machine, which automatically identifies cup sizes and sorts them into the right output channels for packaging.

2.Why are three machines better than one?

Traditional paper cup production lines can usually only process one cup type at a time, and if you want to change the size, you have to stop the machine to change the mold and adjust the packaging. But this three-machine linkage production line breaks the convention: three OCM12 high-end paper cup machines can produce paper cups of different sizes (such as 8oz, 12oz, and 16oz) respectively, running at the same time without reducing efficiency; the matching MY-450X packaging machine can intelligently identify the cup type and automatically push out the packaged products according to size, without manual intervention and sorting. This design is particularly suitable for: orders containing multiple specifications; customers require flexible and fast switching of cup types; factories that hope to shorten delivery time and reduce downtime for adjustment.

3.Core equipment, OCM12 High-end Paper Cup Machine

OCM12 is a high-end paper cup machine tailored for medium- and high-speed production scenarios. It is suitable for producing 1.5oz-16oz cold/hot drink paper cups, supports PE coated paper, and has a stable speed of 80-100pcs/min. It is equipped with a servo motor, high-precision mold components, ultrasonic heating technology with precise temperature control, and a smart touch screen to ensure that the paper cups are beautifully formed and tightly sealed. In addition, OCM12 is covered with a whole piece of steel plate, which increases the overall weight while ensuring that the machine's operating efficiency is improved.

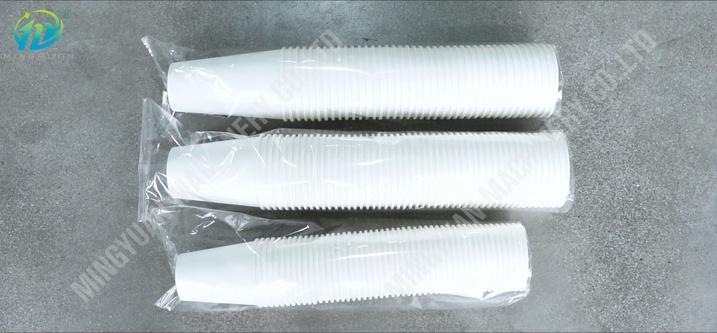

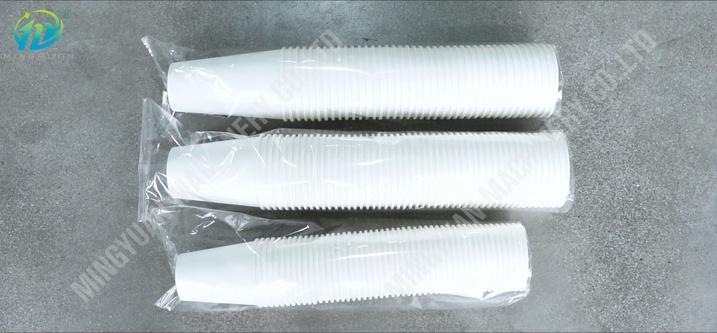

4.Innovation in packaging process, MY-450X rolling knife

MY-450X packaging machine is our automatic packaging solution designed for medium- and high-speed paper cup production lines. It supports a packaging efficiency of 40–180 bags/min, adopts the back sealing process, and the packaging effect is regular and tight, suitable for LDPE/HDPE film. It is equipped with 3 servo motors, PLC touch screen controller, flexible setting and cutting of bag length, saving time and film. Sensor fault detection function, clear fault display. High-sensitivity photoelectric color mark tracking and digital input cutting position make sealing and cutting more accurate, non-stick knife, and no waste of packaging film. The special highlight of this equipment is its multi-specification intelligent recognition function, which can automatically perform post-packaging diversion according to the size difference of paper cups. In other words, even if three paper cup machines produce three sizes of paper cups simultaneously, MY-450X can still accurately identify, package and classify and convey, achieving high automation. At the same time, it is also an ideal machine for packaging napkins, facial masks, biscuits, bath balls, chocolates, bread, moon cakes, daily necessities, industrial parts and other types of conventional items.

5.Less Labor, Faster Delivery — Even Small Factories Can Handle Complex Orders

In the past, when faced with mixed orders, frequent mold changes, manual operations, sorting and packaging were required, which was not only slow but also prone to errors. Now, only one line is needed to complete the entire production and packaging process of multiple cup types at one time, saving manpower, improving accuracy, and making small and medium-sized enterprises more confident in accepting customized orders. Each OCM12 high-end paper cup machine runs at a speed of 80-100pcs/min, and the total production capacity of three machines can reach 300pcs/min. The 450X packaging machine adopts a hob-type back-sealing process, and the packaging effect is regular and tight, which is particularly suitable for export and mid-to-high-end paper cup packaging needs.

6.Who Benefits Most from This Line?

Large-scale and efficient production: Applicable to enterprises that require large-scale and efficient production, especially for markets with high demand such as takeaway, catering, chain beverage stores, etc.

High-end customer needs: For enterprises that require fast production and high-quality packaging, it can be applied to large-capacity, high-quality paper cup production.

Standardized production needs: Applicable to the production of a large number of standardized paper cups, suitable for markets with high requirements for packaging and quality such as takeaway and fast food industries.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China