If you are just starting out in the paper cup industry, or are planning to build a small-scale, flexible paper cup processing plant with a limited budget, then this OCM12 + MYC-D production line is really worth a look. While maintaining output and quality, it does not require too high an investment, nor does it require complicated operations. It is a classic combination that can really "feed a small factory."

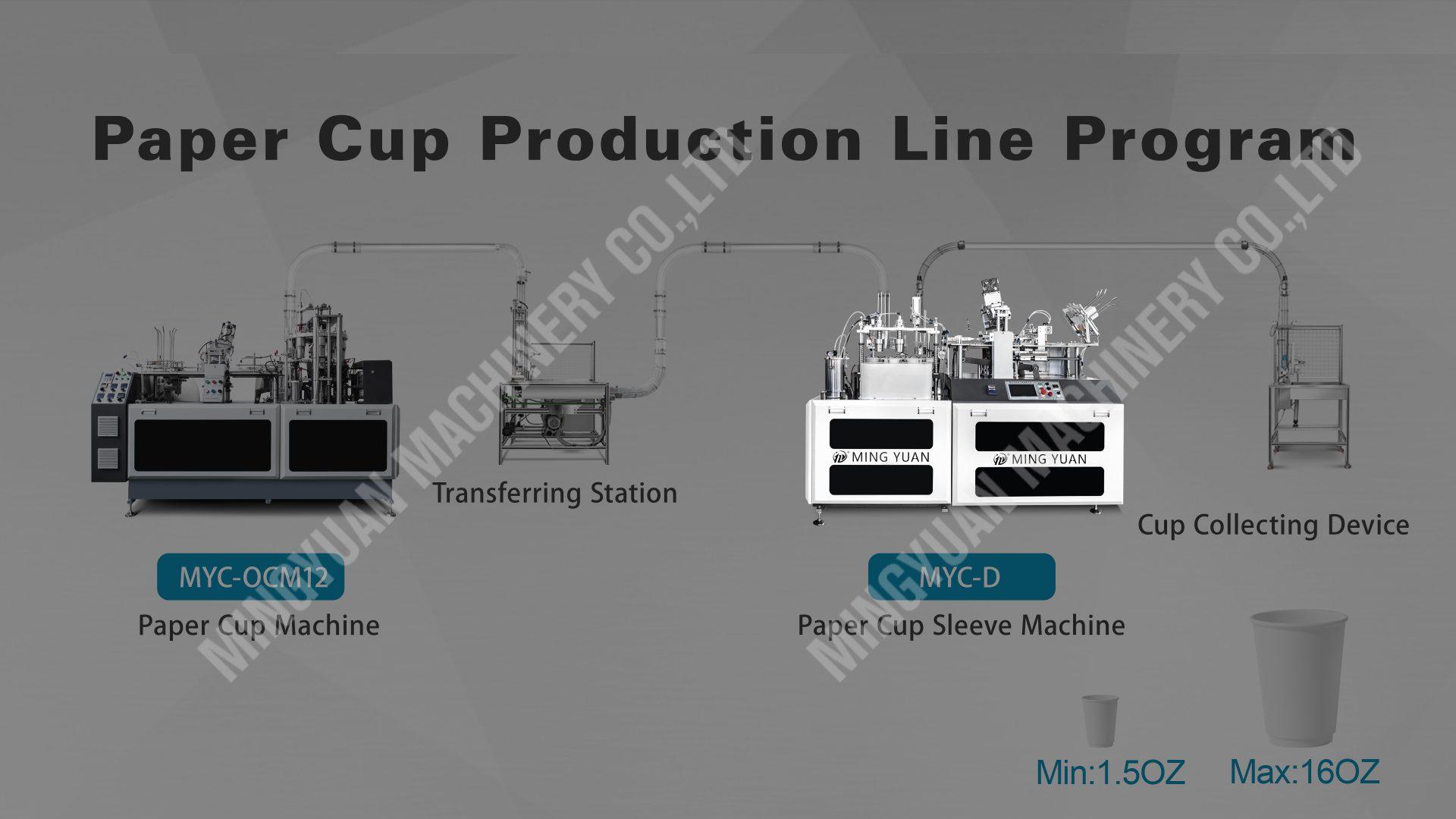

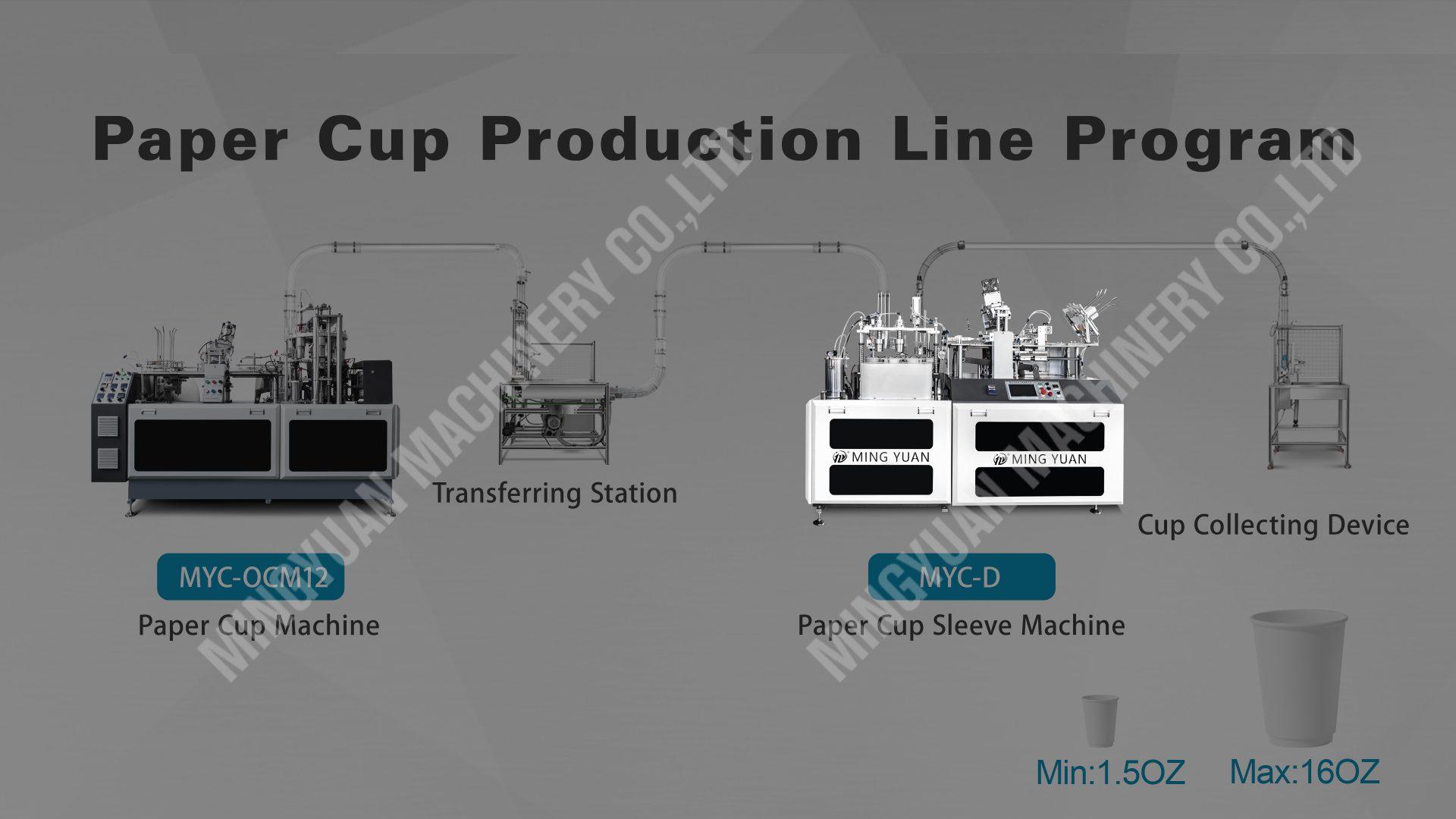

1.OCM12 Paper Cup Machine + MYC-D Paper Cup Sleeve Machine workflow

This paper cup production line can produce two types of paper cups, the first is a hollow double-layer paper cup, and the other is a double-layer corrugated paper cup. This production line consists of a paper cup machine for producing inner cups, a paper cup transfer station, and a paper cup sleeve machine for producing cup sleeves. The raw materials enter the paper cup machine for paper suction, side sealing, cup bottom punching and feeding, heating, knurling, cup top curling, and cup collection, and then are sent to the paper cup sleeve machine by air blowing. After entering the paper cup sleeve machine, the mechanical arm glues the side of the raw materials, seals the sides, feeds the cups, fits them, curls the bottom, and finally forms them and sends them to the paper cup collection rack.

2.OCM12 Paper Cup Machine

Ocm12 High speed paper cup machine speed is 80-100pcs/min . Cup size range is from 1.5-16 OZ . High-precision open cam and full gear driving system make it run more stably. The automatic oil lubrication system guarantees all mechanical parts to work more smoothly . 12 Pieces of Sensors which can stop automatically if the machine has any problem.It is the best choice for beginners to make paper cups.

3.MYC-D Paper Cup Sleeve Machine

The MYC-D paper cup sleeve machine has a speed of 50-60pcs/min, and the cup size range is 4-16oz.PE coated paper,Gloss printed paper(gray based paper with gloss printing),other film coated paper(can be welded by ultrasonic).This machine is equipped with a servo motor, hot melt glue for sealing, which is more accurate and stable, and uses a high-quality brand electrical system, with better quality and longer service life. The edge sealing station uses an ultrasonic heater to seal the paper sleeve. In order to prevent malfunctions from affecting the production of paper cups, the machine is equipped with a fault detection sensor. If there is a problem, it will automatically stop working, which can greatly improve the safety of operation.

4.Which customers are suitable

·Start-up paper cup processing factory

Suitable for: Just started a business with limited budget, want to quickly build a usable production line

Advantages: Low investment threshold, simple operation, easy maintenance

·Takeaway/beverage chain store supporting factory

Suitable for: Provide customized cups for local milk tea shops, coffee shops, and takeaway brands

Advantages: Produce a wide range of cup shapes from 2-16oz, can stick cup sleeves, beautiful and scald-proof

·Local paper cup customization OEM point

Suitable for: Specialize in small batch customization for local customers, such as wedding, festival, and event cups

Advantages: Adjustable cup shape, easy switching, suitable for short orders and multiple styles

·Small and medium-sized paper cup printing factory

Suitable for: Have printing equipment and want to switch from "printing cup fans" to "making finished paper cups"

Advantages: Combined with cup sleeve machines, provide a more complete solution

·Paper cup regional market operators

Suitable for: Do brand OEM, take regional orders, and hope to control delivery time and cost

Advantages: Build your own small production line, say goodbye to outsourcing, and see visible profit improvement

·Small-scale investors who want to verify or test the paper cup product line

Suitable for: Make a small investment, test the market response first, and then expand later

Advantages: Good cost control, short payback period, low risk

5. This line is not "low-end" but "high cost performance"

For customers with limited budgets but certain requirements for production capacity and stability, OCM12 + MYC-D is the "first reliable paper cup production line". With low investment threshold, considerable output and convenient maintenance, it not only solves the investment pressure in the initial stage, but also retains the flexibility of subsequent upgrades. It is a true portrayal of "leveraging the greatest potential with the lowest cost".

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China