As global environmental awareness increases, traditional plastic products are gradually being replaced by biodegradable materials, and paper cups have become one of the first choices in the food and beverage packaging industry. In this context, the efficiency and quality of paper cup production equipment are particularly critical. Today, we will take you to fully understand a medium-sized paper cup production line with extremely high cost-performance and wide application range: MY-120 paper cup machine + DW-120 Paper cup sleeve machine production line.

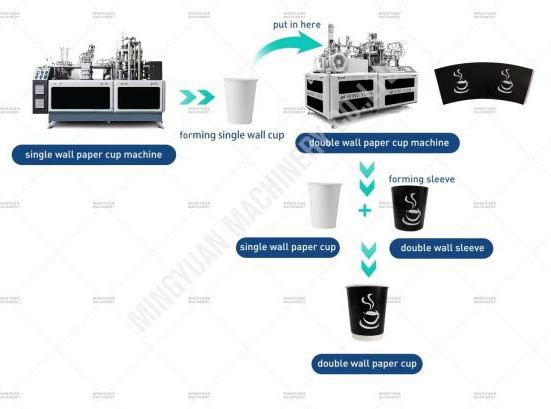

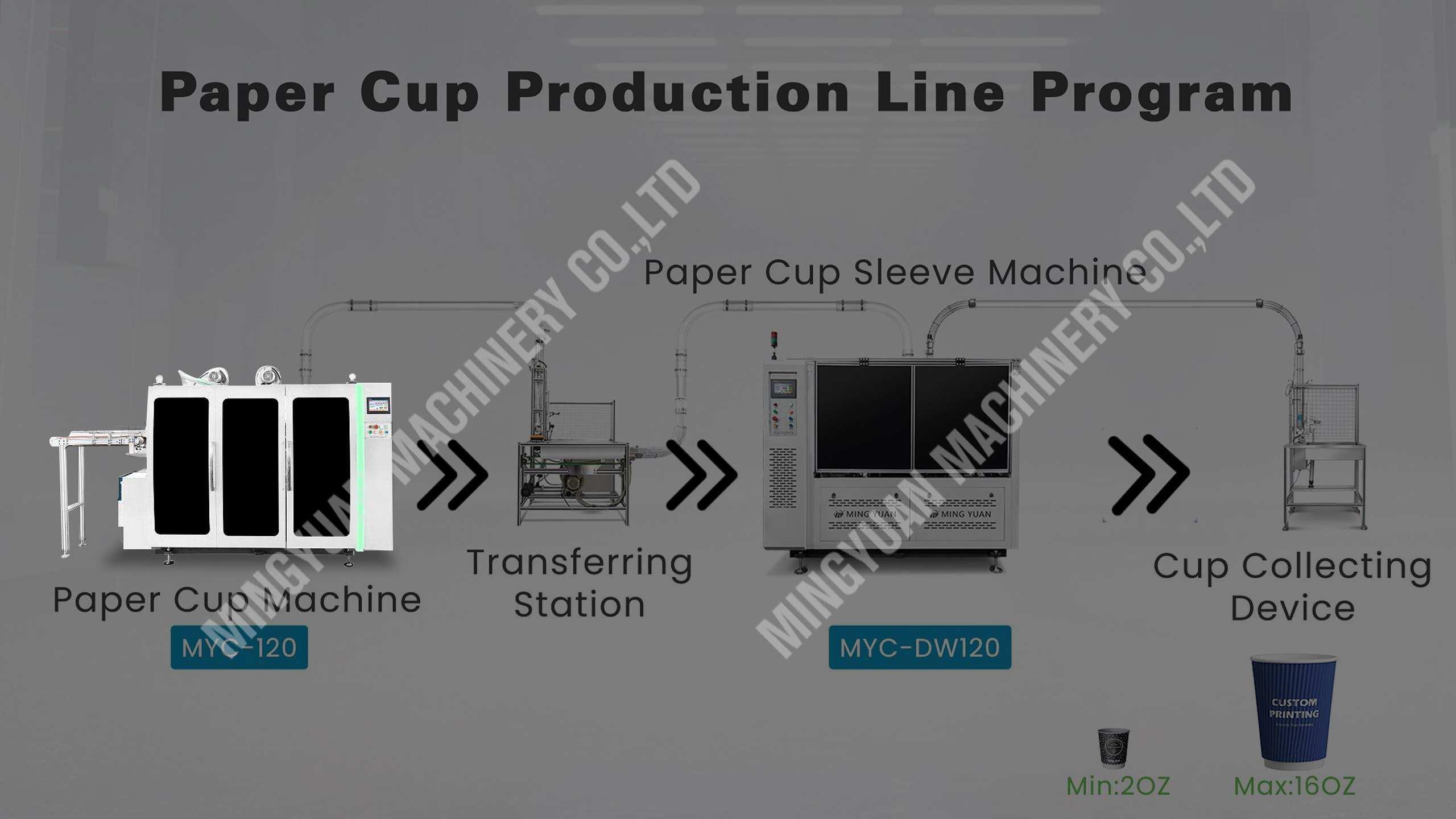

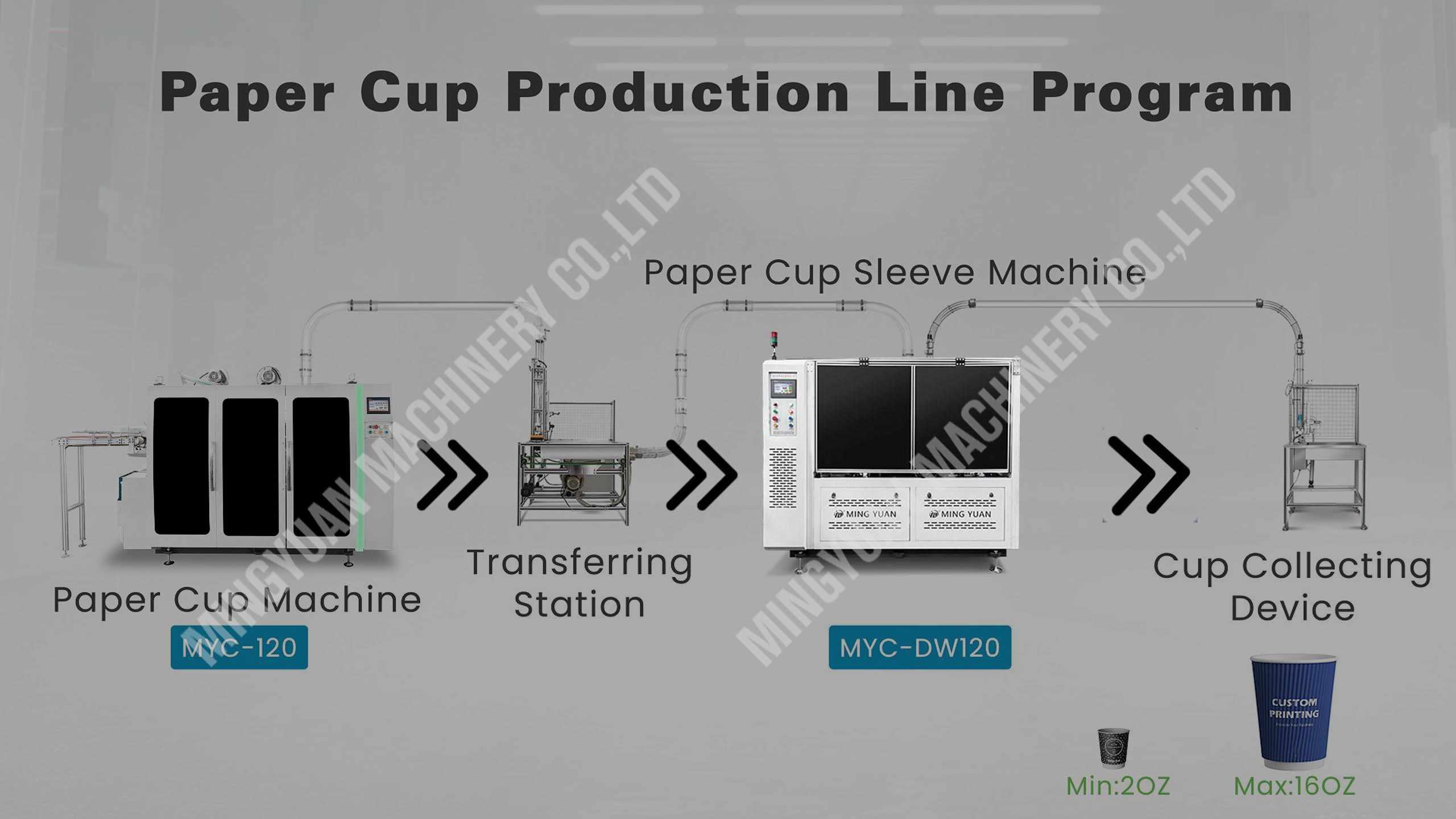

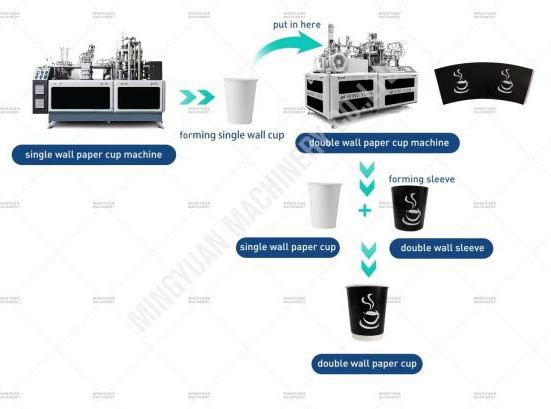

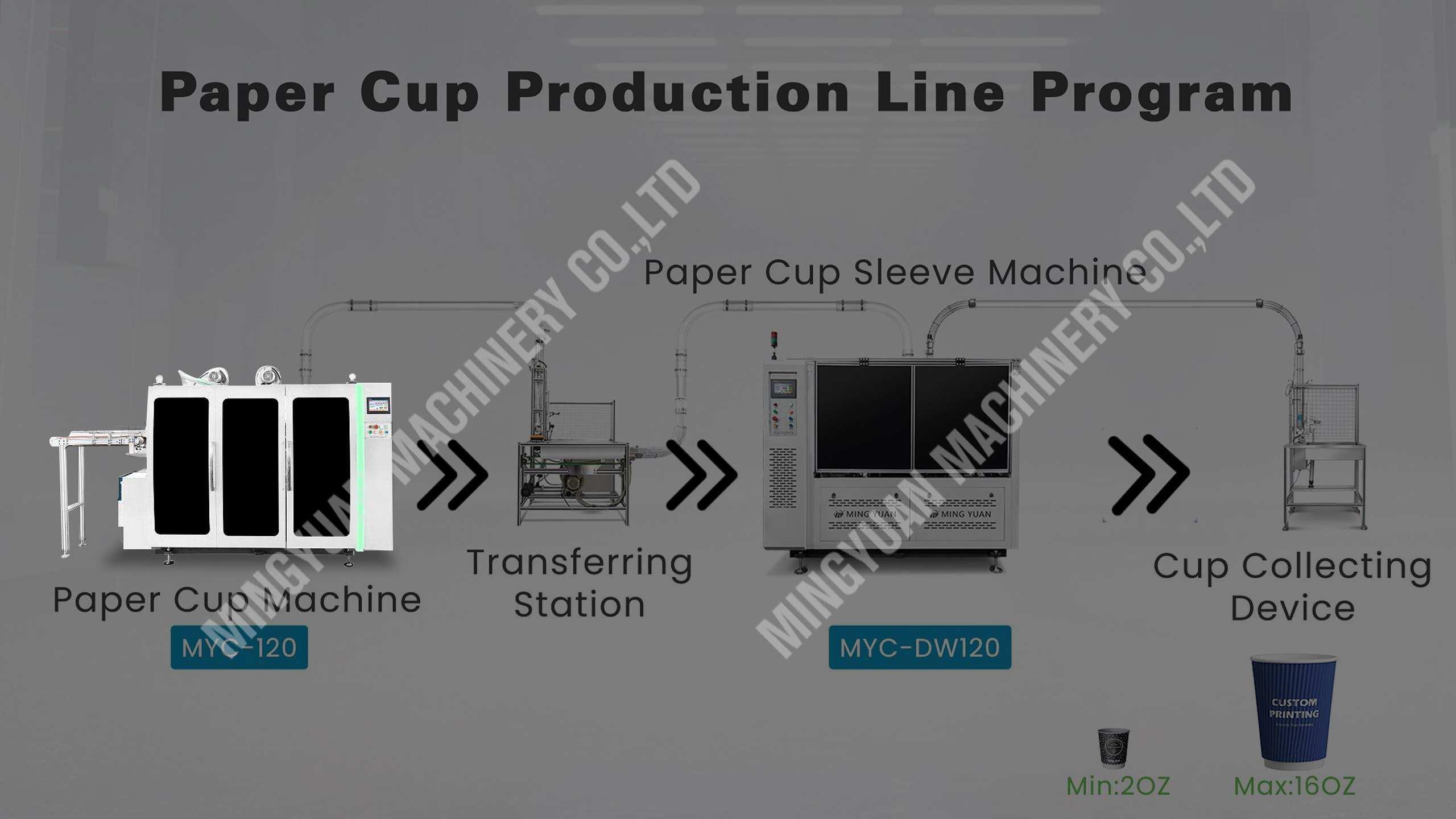

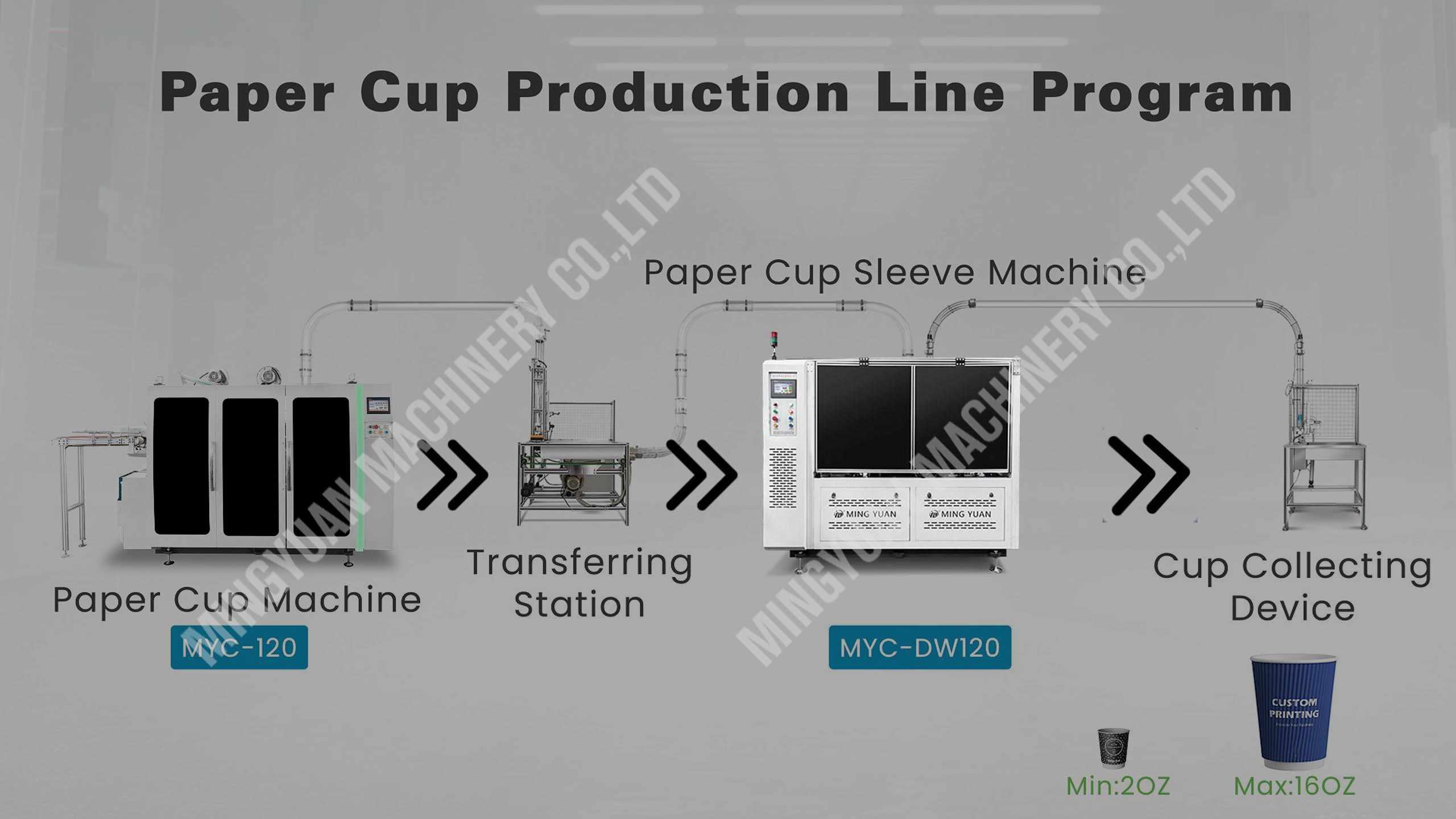

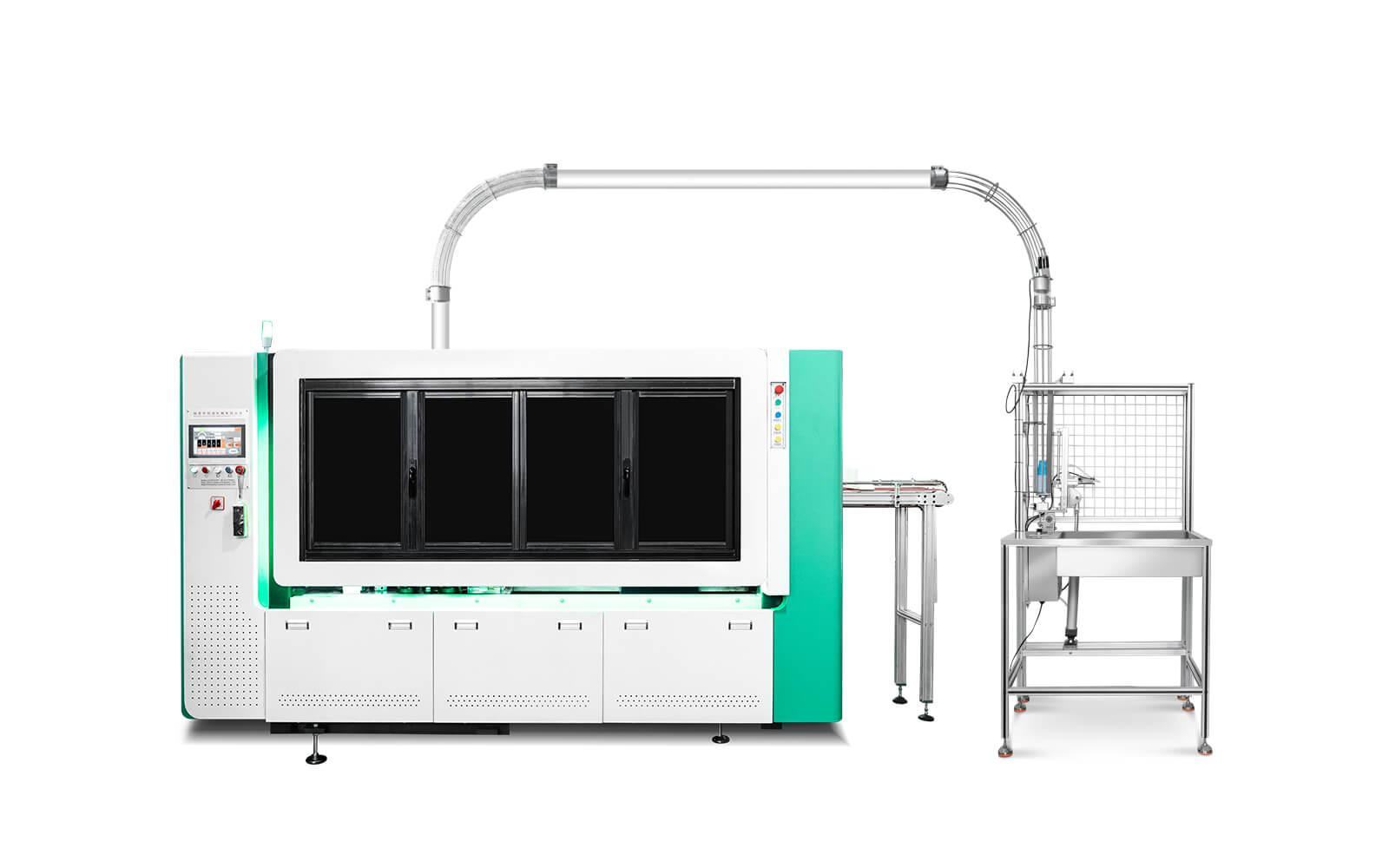

1.How MYC-120 Paper cup machine+DW120 Paper cup sleeve machine production line works?

This production line is used to produce double-layer paper cups.MYC-120 high speed Paper cup machine is used to produce single-layer paper cups. The double turn plate structure design enables the production efficiency of the paper cup machine to reach at least 130 pcs/min. The small turn plate is used for the top curling of the paper cup, and the large one is used for the bottom knurling and punching. The produced single-layer paper cups are transported to the transfer cup collection rack by air blowing for counting and collection. The sorted paper cups are transported to the double-layer paper cup sleeve machine-DW120 by air blowing again, and the cup sleeves are put on using hot glue and bottom curling technology. This Paper cup sleeve machine can be customized with a hot melt system, and the glue coating machine used is a Switzerland brand to ensure the strength of the cup sleeve.This production line can produce up to 6,600 pieces per hour, which can meet the production needs of most factories and is the best choice to improve factory production capacity and product quality.

2.MY-120 Paper Cup Machine: Stable and Efficient, Covers Mainstream Cup Sizes

The MY-120 is designed for 2–12oz hot and cold drink cups, with a capacity of 130–150 pcs/min, ideal for tea, coffee, and cold drink cups.

Applicable Materials:Single/Double PE Coated Paper、Aluminum Foil Laminated Paper

Key Features:low failure rate, easy maintenance、Supports mold customization

3. DW-120 Paper Cup Sleeve Machine : Enhances the Added Value of Paper Cups

The DW-120 Paper Cup Sleeve Machine produces anti-scald sleeves for 8–16oz cups at speeds of 110–120 pcs/min.Matching the efficiency of the paper cup machine, it realizes efficient linkage of the production line.

Applicable Materials:PE Coated Paper、Glossy Paper

Sleeve Benefits:Insulation from heat、Adds structural strength、Branding & customization space

4. Advantages of production line combination

It is suitable for small and medium-scale production, especially for enterprises that need to produce environmentally friendly paper cups.

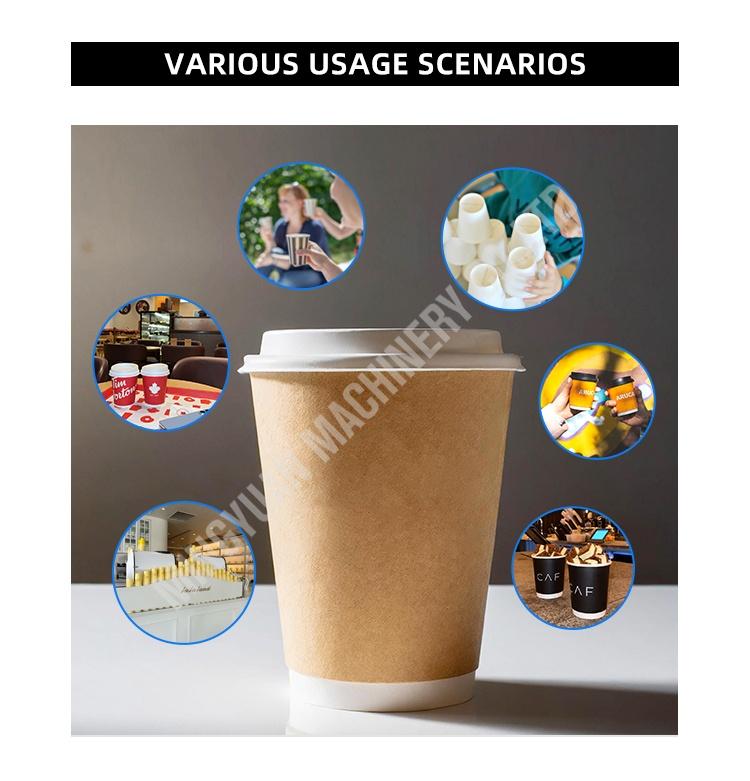

Applicable scenarios:

Small and medium-scale production: This production line is suitable for small and medium-sized enterprises with relatively stable daily needs and moderate production volume, especially for customers who have high requirements for paper cup production quality.

Beverage industry, catering industry: Suitable for the production of various medium-sized (2-16oz) paper cups, widely used in coffee shops, catering takeaways and small beverage shops.

Environmental protection needs: This combination is suitable for coated paper and aluminum foil paper, which can meet the demand for environmentally friendly paper cups and is suitable for markets with strict environmental protection requirements.

Requirements that can be met:

Adapt to various paper types: Suitable for coated paper and aluminum foil paper, can produce high-quality single-layer or double-layer paper cups, suitable for making hot and cold drinking paper cups.

Medium production demand:100-120pcs/min can meet the daily medium-scale production needs.

Efficient production: The matching DW-120 paper cup sleeve machine also has relatively high production efficiency, which further improves the overall output of the production line.

5.The Ideal Choice for Flexibility and Efficiency:MYC-120 Paper cup machine+DW120 Paper cup sleeve machine production line

The MYC-120 Paper cup machine+DW120 Paper cup sleeve machine combo provides a stable, efficient, and material-compatible mid-speed paper cup solution. It meets real-world production demands across various sizes and markets—making it a truly cost-effective option.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China