Paper cup manufacturing machines play a vital role in the production of disposable paper cups, which are widely used in the food and beverage industry. These machines offer numerous advantages and features that make them essential equipment for businesses involved in paper cup production.

Efficiency and Productivity

One of the key advantages of paper cup manufacturing machines is their high efficiency and productivity. These machines are designed to automate the production process, allowing for faster and more consistent manufacturing of paper cups. With the ability to produce a large number of cups in a short amount of time, businesses can meet the demands of their customers efficiently.

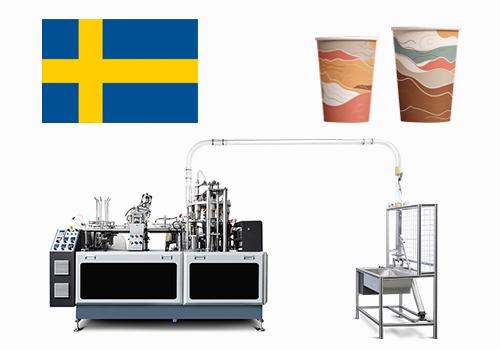

Versatility in Cup Sizes

Modern paper cup manufacturing machines offer versatility in producing various cup sizes to cater to different customer needs. Whether it's a small espresso cup or a large takeaway coffee cup, these machines can be easily adjusted to manufacture cups of different sizes without the need for extensive retooling.

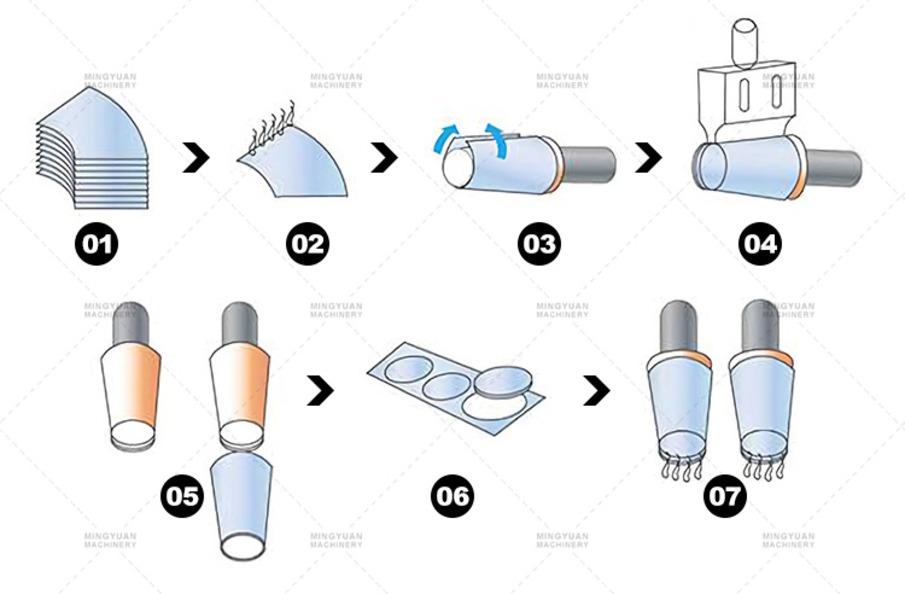

Quality Control

Paper cup manufacturing machines are equipped with advanced technology that ensures high-quality production. From precise cutting and shaping to accurate sealing and finishing, these machines maintain consistency in cup quality throughout the production process. This quality control feature helps businesses deliver reliable and durable paper cups to their customers.

Cost-Effectiveness

Investing in a paper cup manufacturing machine can lead to long-term cost savings for businesses. By reducing the need for manual labor and minimizing material waste, these machines help lower production costs and improve overall profitability. Additionally, the efficiency of these machines results in higher output, maximizing the return on investment.

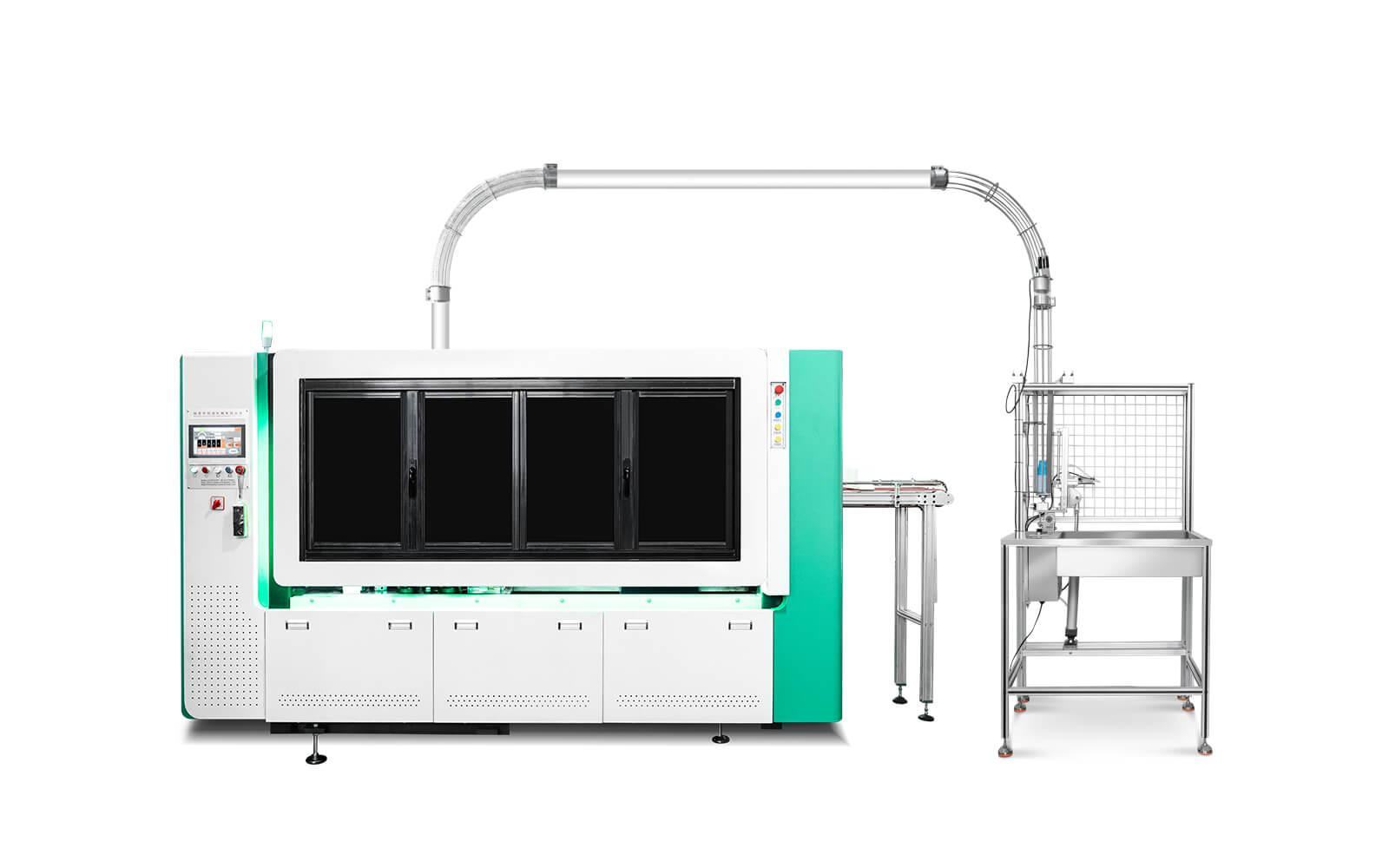

Ease of Operation

Another advantage of paper cup manufacturing machines is their user-friendly design, making them easy to operate even for individuals with minimal experience. With intuitive controls and clear instructions, operators can quickly set up the machine, monitor the production process, and make adjustments as needed. This ease of operation enhances productivity and reduces the risk of errors during manufacturing.

Energy Efficiency

Many modern paper cup manufacturing machines are designed with energy-efficient features to reduce environmental impact and lower operating costs. These machines incorporate smart technologies that optimize energy usage during production, such as automatic shutdown functions and power-saving modes. By minimizing energy consumption, businesses can operate more sustainably and contribute to a greener environment.

Maintenance and Durability

Paper cup manufacturing machines are built to withstand the rigors of continuous operation, ensuring durability and longevity. With regular maintenance and servicing, these machines can remain in optimal condition, reducing the risk of breakdowns and downtime. The robust construction and high-quality components of these machines contribute to their reliability and longevity in the manufacturing environment.

Customization Options

Some paper cup manufacturing machines offer customization options that allow businesses to create unique and branded paper cups. These machines can be equipped with printing capabilities to add logos, designs, or promotional messages to the cups during the manufacturing process. This customization feature enables businesses to enhance their branding efforts and stand out in the market.

Conclusion

In conclusion, paper cup manufacturing machines provide a wide range of advantages and features that benefit businesses involved in paper cup production. From efficiency and productivity to quality control and customization options, these machines play a crucial role in meeting the demands of the food and beverage industry. Investing in a paper cup manufacturing machine can lead to improved production processes, cost savings, and enhanced competitiveness in the market.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China