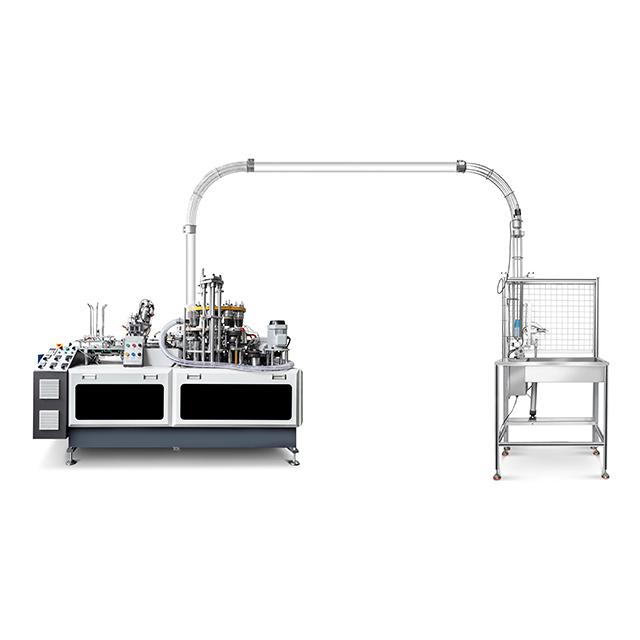

Paper cup and plate making machines have revolutionized the production process of disposable paper products, offering numerous advantages and advanced features that cater to the growing demand for eco-friendly and sustainable alternatives to plastic. These machines are equipped with cutting-edge technology and innovative design, making them essential equipment for businesses in the food and beverage industry, event management, and catering services.

1. Efficient Production Capacity

One of the key advantages of paper cup and plate making machines is their efficient production capacity. These machines are capable of producing a large volume of paper cups and plates within a short period, ensuring high productivity and meeting the demands of large-scale events, restaurants, and cafes. The automated operation and high-speed functionality contribute to streamlining the production process, allowing businesses to meet tight deadlines and customer requirements.

2. Versatility in Product Sizes

The versatility offered by these machines in producing various sizes of paper cups and plates is an essential feature. Businesses can customize their production based on specific requirements, offering a range of cup and plate sizes to accommodate different serving portions and purposes. This flexibility caters to diverse business needs and consumer preferences, making the machines an adaptable and versatile investment for businesses across different sectors.

3. Sustainable Material Usage

With the increasing emphasis on sustainability, paper cup and plate making machines facilitate the usage of eco-friendly and biodegradable materials. By utilizing paper as the primary raw material, these machines contribute to reducing the environmental impact associated with traditional plastic-based disposable products. This aligns with the global shift towards eco-conscious practices and enables businesses to offer environmentally friendly solutions to their customers.

4. Cost-Effectiveness

Investing in a paper cup and plate making machine offers long-term cost-effectiveness for businesses. The use of paper as a raw material is relatively economical compared to plastic, contributing to cost savings in production. Additionally, the efficient production capacity and automated operation minimize labor costs and enhance overall operational efficiency, making it a financially prudent investment for businesses of varying scales.

5. Enhanced Customization and Branding Opportunities

These machines enable businesses to incorporate branding elements and customize the design of paper cups and plates. This feature is particularly beneficial for businesses seeking to establish a distinct brand identity and enhance their marketing efforts. Customized packaging adds a professional touch to the products, contributing to brand recognition and customer loyalty, thereby creating a competitive edge in the market.

6. User-Friendly Operation and Maintenance

The user-friendly design of paper cup and plate making machines simplifies operation and maintenance, making it accessible for operators with varying levels of expertise. The intuitive controls and minimal manual intervention streamline the production process, reducing the likelihood of errors and enhancing operational efficiency. Additionally, the low maintenance requirements contribute to prolonged machine lifespan and reliable performance.

7. Compliance with Quality and Safety Standards

These machines are engineered to comply with stringent quality and safety standards, ensuring the production of paper cups and plates that meet regulatory requirements. The use of high-quality materials and precision manufacturing processes results in durable, hygienic, and safe products. This instills confidence in businesses and consumers regarding the reliability and integrity of the paper-based disposable products.

8. Integration of Advanced Technology

Modern paper cup and plate making machines integrate advanced technology, such as digital controls, automated stacking, and precision cutting mechanisms. This technological integration enhances the precision, speed, and overall performance of the machines, contributing to consistent product quality and operational reliability. The incorporation of state-of-the-art components ensures optimal functionality and adaptability to evolving industry requirements.

Conclusion

In conclusion, the advantages and features of paper cup and plate making machines encompass efficiency, versatility, sustainability, cost-effectiveness, customization, user-friendliness, compliance with standards, and technological integration. These attributes make these machines indispensable assets for businesses seeking to streamline production, uphold sustainability practices, and deliver high-quality disposable paper products to the market.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China