Operating a new top paper cup machine requires not only technical knowledge but also strict adherence to safety guidelines. These machines are vital in the production of disposable cups used widely in various industries. However, improper handling can lead to accidents and injuries. This article outlines essential safety instructions for operating a paper cup machine, ensuring a safe and efficient working environment.

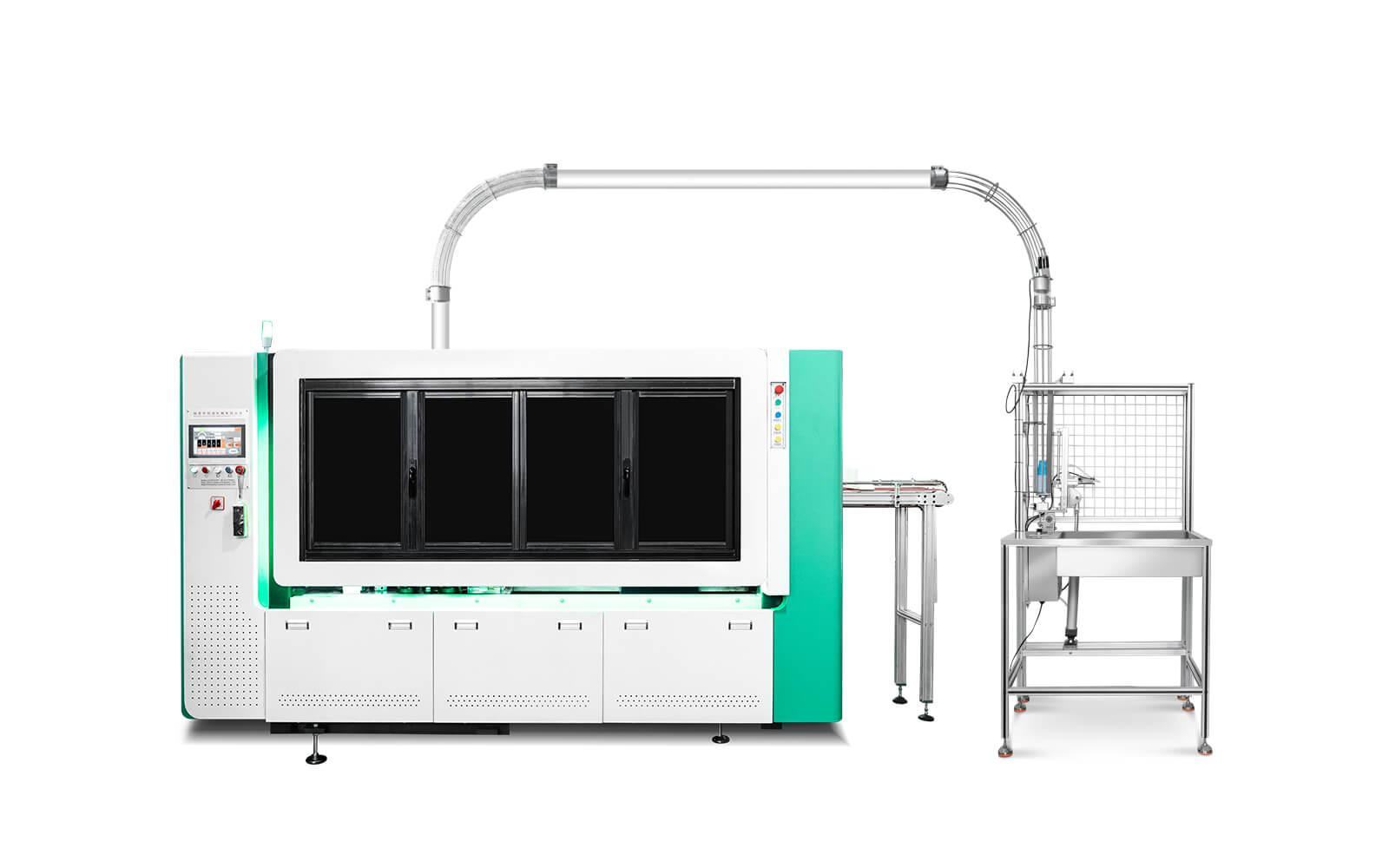

Understanding the new top paper cup machine

The new top paper cup machine is designed to manufacture cups from rolls of paper. It employs various processes such as feeding, sealing, and forming to produce high-quality products. Familiarity with the machine’s components and operations is crucial for safe usage. Operators should read the manual thoroughly to understand the specific features and functions of their model.

Personal Protective Equipment (PPE)

Before operating the machine, it is vital to wear appropriate personal protective equipment. This includes safety goggles to protect the eyes from debris, ear protection to guard against noise, and gloves to prevent cuts and abrasions. Additionally, operators should wear non-slip footwear to minimize the risk of slips and falls around the machine area.

Machine Inspection and Maintenance

Regular inspection and maintenance of the new top paper cup machine are critical for ensuring safe operation. Operators should conduct daily checks for any signs of wear or damage, especially on moving parts. Lubrication should be performed as per the manufacturer’s guidelines to ensure smooth operation. Any issues should be reported immediately to a supervisor, and the machine must be taken out of service until repairs are made.

Safe Operating Procedures

Operators must follow safe operating procedures at all times. Before starting the machine, ensure that all guards and safety devices are in place and functioning correctly. Operators should also make sure that the area around the machine is clear of any hazards or obstructions. It is essential to never bypass safety features, as this can lead to severe accidents.

Emergency Preparedness

In case of an emergency, operators should be well-prepared. Familiarize yourself with the location of emergency stop buttons and how to use them. Regular drills should be conducted to ensure that all personnel know how to respond effectively in various emergency situations, such as machine malfunction or personal injury. An updated first aid kit should always be accessible in the work area.

Electrical Safety

Since paper cup machines rely heavily on electrical components, operators must practice electrical safety. Ensure that all electrical connections are secure and free from damage. Never operate the machine with wet hands or while standing on wet surfaces. If an electrical issue arises, turn off the power supply before attempting any troubleshooting or repairs.

Training and Supervision

All operators should undergo comprehensive training before using the machine. Ongoing training sessions can help reinforce safety protocols and introduce new safety measures as they become necessary. Additionally, experienced supervisors should oversee new operators until they demonstrate proficiency and understanding of safe practices.

Proper Material Handling

Handling materials correctly is crucial in preventing accidents. Operators should be trained on how to load and unload paper rolls safely. Use mechanical aids whenever possible to lift heavy loads instead of attempting to do so manually. Proper organization of materials also reduces clutter and minimizes risks in the working environment.

Dealing with Paper Jam Issues

Paper jams are common occurrences in new top paper cup machines. However, operators should never attempt to clear a jam while the machine is running. Always stop the machine and disconnect the power before addressing the jam. Follow the manufacturer’s instructions for safely removing jammed paper to avoid injury.

Maintaining a Clean Work Environment

A clean work environment significantly enhances safety. Operators should regularly clean the area around the paper cup machine to remove any spills or debris. Waste materials should be disposed of properly, and the workspace should be organized to reduce hazards. Encourage a culture of cleanliness among all employees to maintain safety standards.

Conclusion: Prioritizing Safety in Paper Cup Production

In conclusion, the safety of operators while using new top paper cup machines should be a top priority in any manufacturing facility. By following these safety instructions, operators can minimize risks and create a safer working environment. Regular training, proper maintenance, and adherence to safety protocols will ensure efficient operations and help prevent accidents. Remember, safety is everyone's responsibility, and a proactive approach can lead to a successful and safe workplace.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China