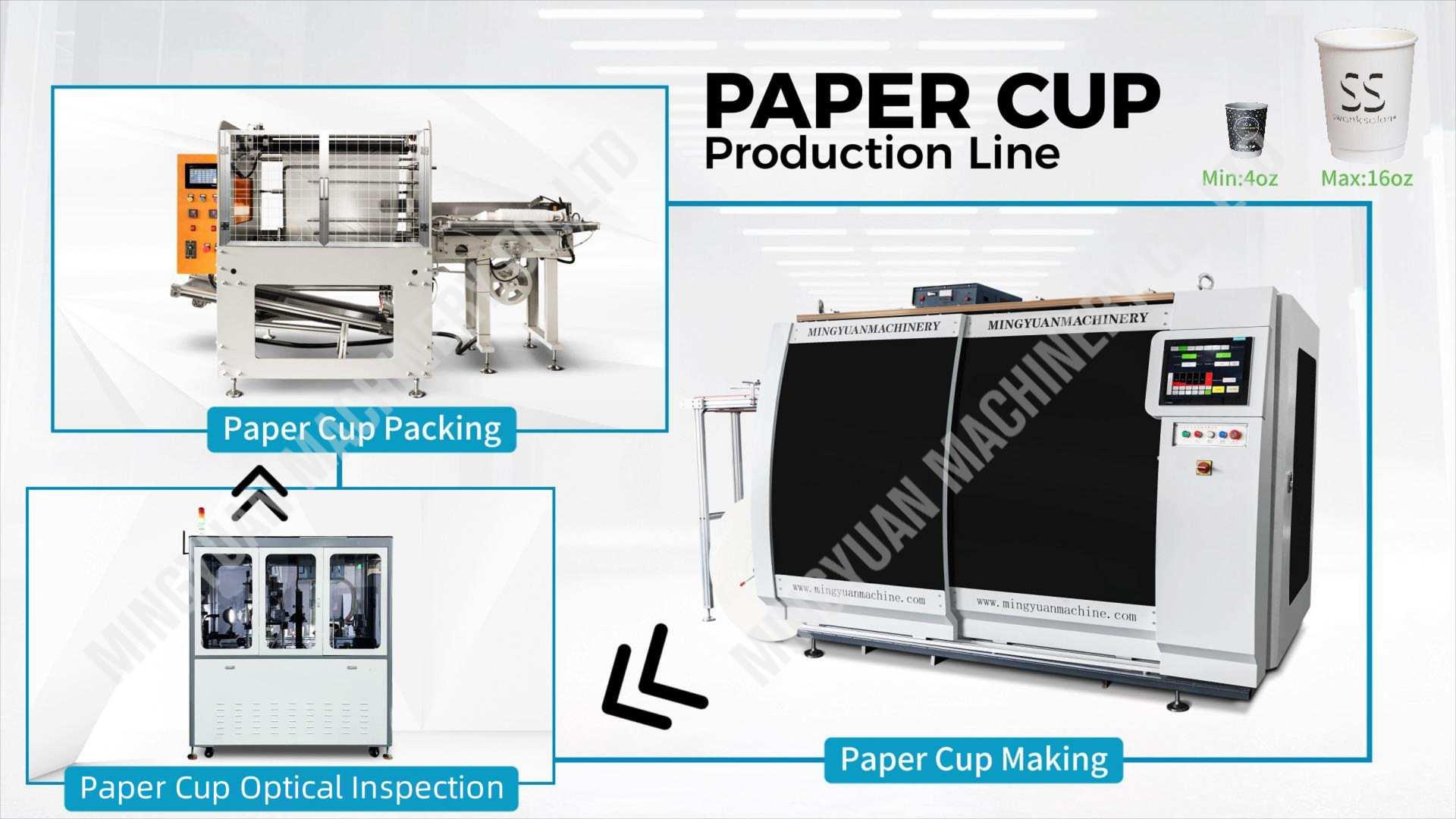

1.Take you into the MYC-180S+ automatic detection + packaging integrated production line

First, according to your needs for paper cups, prepare the base paper. PE/PLA coated paper or aluminum foil paper are all suitable for this production line. Put the prepared paper fan on the conveyor belt and feed it automatically. The paper fan completes paper feeding, paper suction, ultrasonic bonding, cup turning, bottom paper cutting, bottom preheating, bottom paper waste paper automatic cutting and transportation, bottom knurling, and top curling in MYC-180S paper cup machine. The finished cup is transported to the transfer station for counting and collection by air blowing. Similarly, the collected paper cups are sent to the MY-JC001 paper cup optical inspection machine through the air blowing system.Two high-speed industrial cameras are used to inspect the outside and inside of each cup to identify defects such as stains, cracks, deformation, and breakage.Unqualified cups are automatically removed. Qualified paper cups will enter the MY-800 hanging bag packaging machine through air blowing, automatically count, bag, and seal, and finally packaged into neat and hygienic finished product packaging (packaging bags are suitable for LDPE/HDPE film).

2.Analysis of three core devices

|

Function

|

Machine

|

Speed

|

Highlight

|

|

Paper cup forming

|

MYC-180S

|

160-210 pcs/min

|

Stable forming,multi-size support

|

|

Paper cup Inspection

|

MY-JC001

|

300 pcs/min

|

Optical defect detection

|

|

Paper cup Packaging

|

MY-800

|

15-20 bags/min

|

Auto bagging,clean and hygienic

|

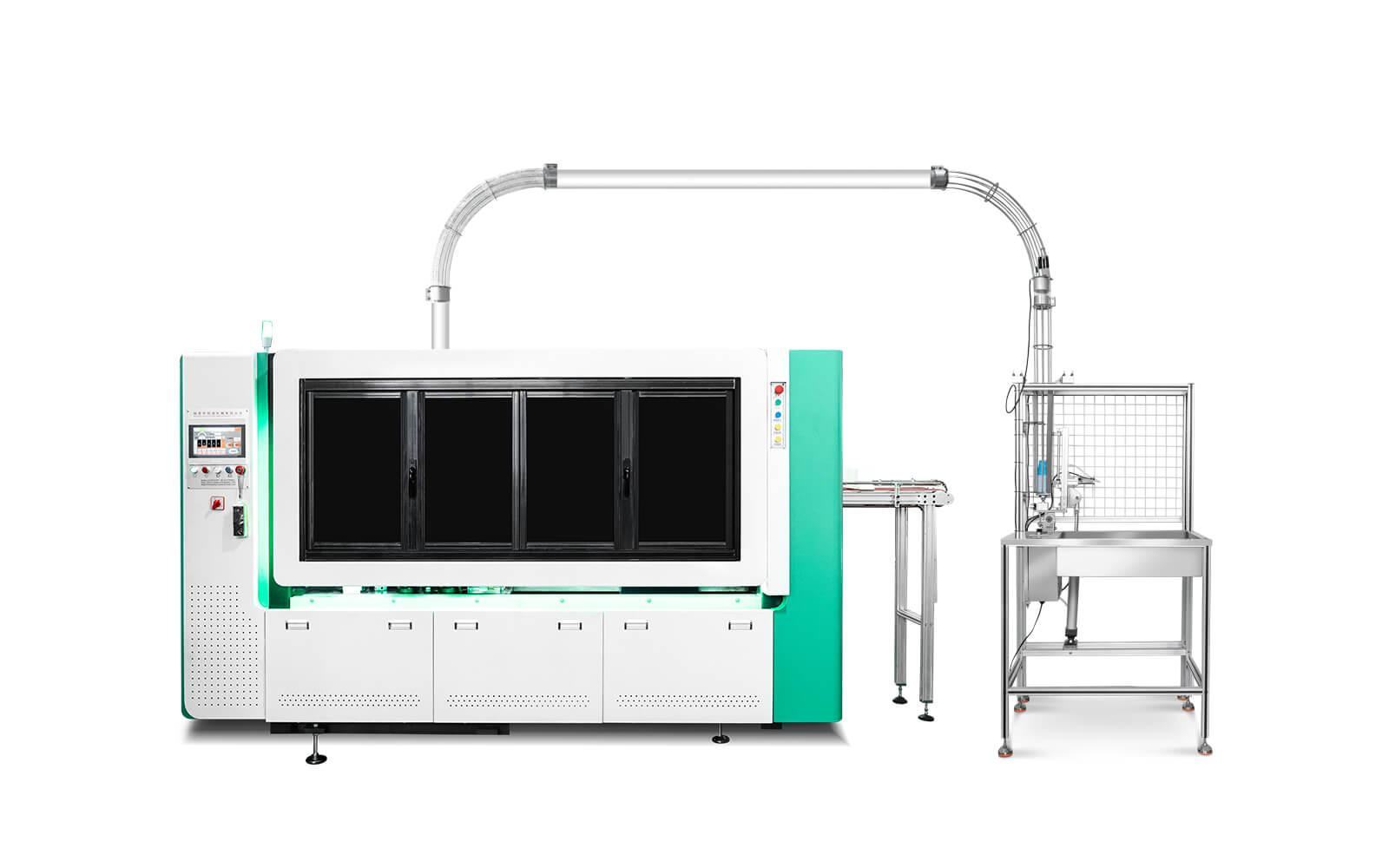

MYC-180S paper cup machine is equipped with 14 servo motors, which accurately control the accuracy of each key position of the paper cup machine and provide sufficient and necessary conditions for the high-speed operation of the paper cup machine. These 14 servo motors accurately control each production action and digitally present the production action on the touch screen, making the adjustment and modification more convenient and simple. MYC-180S paper cup machine adopts a rotary paper suction system and a vacuum pump, which creates the premise for producing 210 pcs/min. Not only that, this machine is also equipped with 5 hot air guns, which heat more effectively and reduce the residence time of paper cups, ensuring the bonding and molding of high-speed production. In daily maintenance, just add an appropriate amount of butter to the bottom oil tank, and the machine will automatically supply oil to the whole machine after running.

MY-JC001 paper cup inspection machine uses industrial camera + image processing algorithm to perform high-speed and fully automatic inspection of the appearance of paper cups. The equipment is equipped with multiple fixed-angle high-resolution cameras and fill light groups, which can take static photos + image comparison analysis of the mouth, body and bottom of the paper cup. If there are stains on the cup body (ink overflow, impurities), damage or cracks on the cup body, deformation or poor curling of the cup mouth, unsealed or broken bottom of the paper cup, it will be automatically removed on the conveyor belt to ensure that only qualified paper cups enter the next link. The entire system is based on a stable image acquisition and edge recognition algorithm, without manual intervention, greatly improving efficiency and stability.

MY-800 hanging bag paper cup packaging machine is an automated packaging equipment designed for medium and high-speed paper cup production lines. It adopts an upper hanging bag packaging device and is suitable for LDPE/HDPE plastic bags of various sizes. It is mainly used to neatly stack qualified paper cups and put them into plastic packaging bags to improve packaging efficiency, unify packaging specifications, and reduce manual operations.

3. Who is the most suitable for this production line?

It is suitable for large-scale production, suitable for high-volume, large-capacity paper cup production, and has high-standard quality control requirements.

Applicable scenarios:

Large-scale production: Suitable for large enterprises or production plants with high requirements for production efficiency, especially for scenarios that require efficient and large-scale production of paper cups.

Large-capacity paper cup production: This production line supports 4-16oz paper cups, which is particularly suitable for making large-capacity paper cups, such as for takeout, catering, fast food and commercial activities.

Markets with high quality requirements: Automated quality inspection through the MY-JC001 inspection machine is particularly suitable for customers with high-standard quality control requirements, such as the food and beverage industry with strict outer packaging.

Requirements that can be met:

High production capacity: MYC-180S paper cup machine has a production capacity of 160-210 pcs/min, which can quickly complete large-scale production tasks and meet the needs of large-volume orders.

High quality standards: The matching MY-JC001 paper cup inspection machine can detect the quality of paper cups in real time, ensuring that each paper cup is free of stains, cracks, damage or wrinkles, ensuring stable product quality.

Fully automated packaging: The efficient packaging function of the MY-800 paper cup packaging machine ensures that the produced paper cups can be quickly packaged and distributed, which is suitable for companies with large demand.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China