—Production analysis using 8oz / 12oz / 16oz as examples

In paper cup production, size is not a simple numerical change.

From 8oz to 12oz, and then to 16oz, each size change involves adjustments to the paper cup machine structure, molds, and some process parameters.

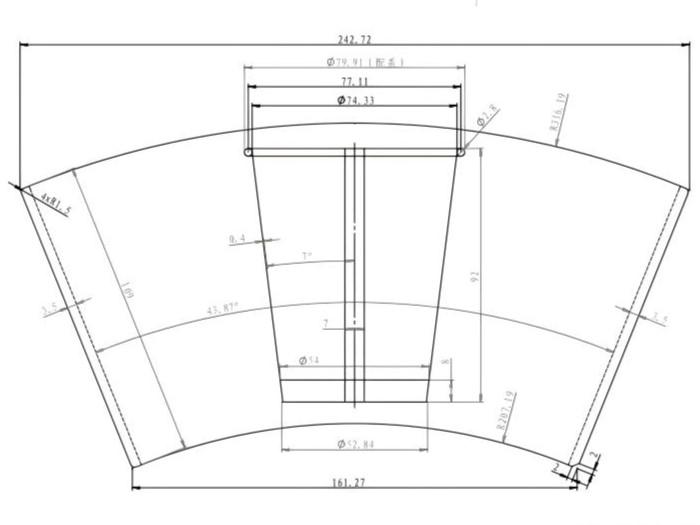

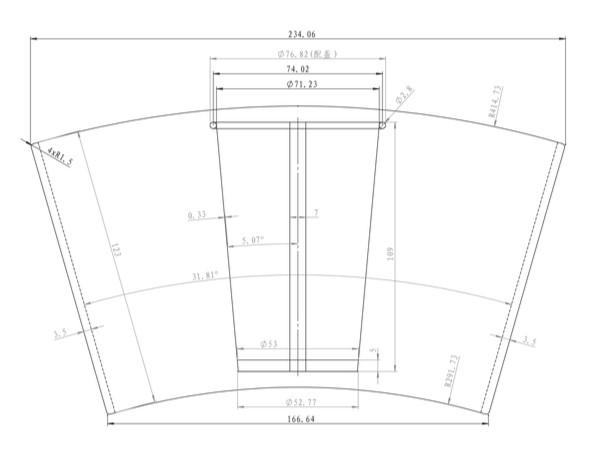

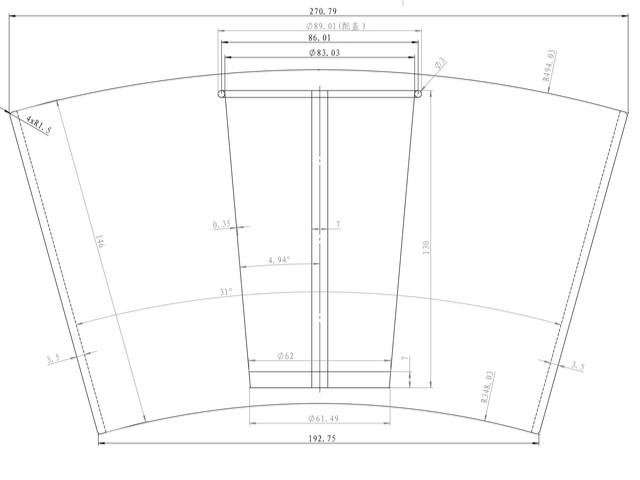

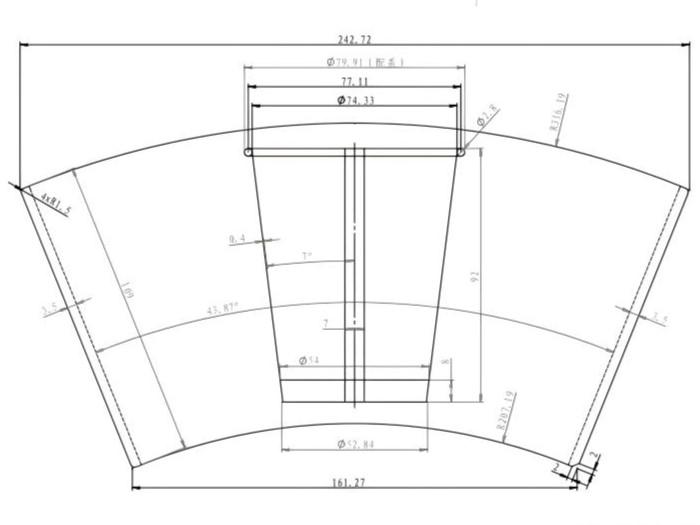

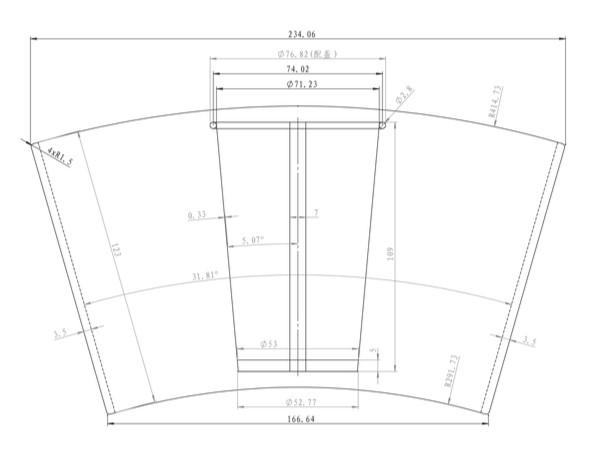

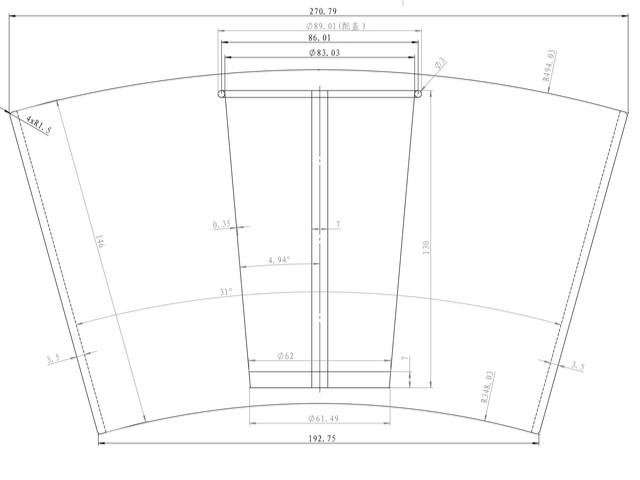

I. Paper Cup Molds: The Core Component

Different paper cup capacities require different unfolded dimensions, making the mold the most crucial element.

Main components include:

Cup Body Mold: For cup bodies of varying heights and tapers.

Bottom Mold: The bottom diameter increases with capacity.

Top Curling Mold: The top curling diameter must perfectly match the cup rim size.

Conclusion: 8oz, 12oz, and 16oz cups cannot share the same mold. Different sizes can only be produced by adding a machine or changing the mold itself.

II. Adjustment of Paper Size and Weight

Changes in paper cup size mean changes in the types and weight of items the cup can hold, necessitating adjustments to the paper configuration.

Paper Fan

8oz Common Configuration: 190–210gsm

12oz Common Configuration: 210–230gsm

16oz Common Configuration: 230–260gsm

Simultaneously, the unfolded dimensions (arc length, height) of the paper fan must match the mold; otherwise, the following problems may occur:

Insecure sealing

Curled edges and deformation

Incorrect cup shape

III. Fine-tuning of Heating and Sealing Parameters

Although the basic structure of the paper cup machine remains unchanged, the

process parameters need to be adjusted appropriately when switching between different capacities.

This mainly focuses on:

Cup body longitudinal sealing heating

Cup bottom heating

Bottom knurling pressure

The reasons are:

Larger capacity cups → Larger contact area

Increased cup height → Changes in heat conduction path

Therefore, in actual production, it is usually necessary to:

Readjust the heating temperature

Adjust the sealing time or pressure

To ensure a firm seal and prevent leakage.

IV. Impact of Forming Cycle Time and Operational Stability

In paper cup production, regardless of whether 8oz, 12oz, or 16oz cups are being produced, the machine's operating speed is not a fixed value but is directly related to the

size, weight, and structure of the paper cup. These changes necessitate corresponding adjustments to the operating cycle time.

As the paper cup size increases, so does its motion inertia.

Increased capacity means:

Taller cup body

Larger diameter of the rim and base

Increased overall weight of a single paper cup

During the paper cup machine's operation, the cup undergoes several actions:

Fan-forming the cup body

Mold rotation

Bottom folding and preheating

Bottom knurling and top edge curling

When the paper cup size increases:

Inertia during movement is greater

Stability requirements are higher during indexing and pauses

If the operating speed for smaller cups is maintained, the following are likely to occur:

Turntable wobbling

Positioning misalignment

Increased machine wear

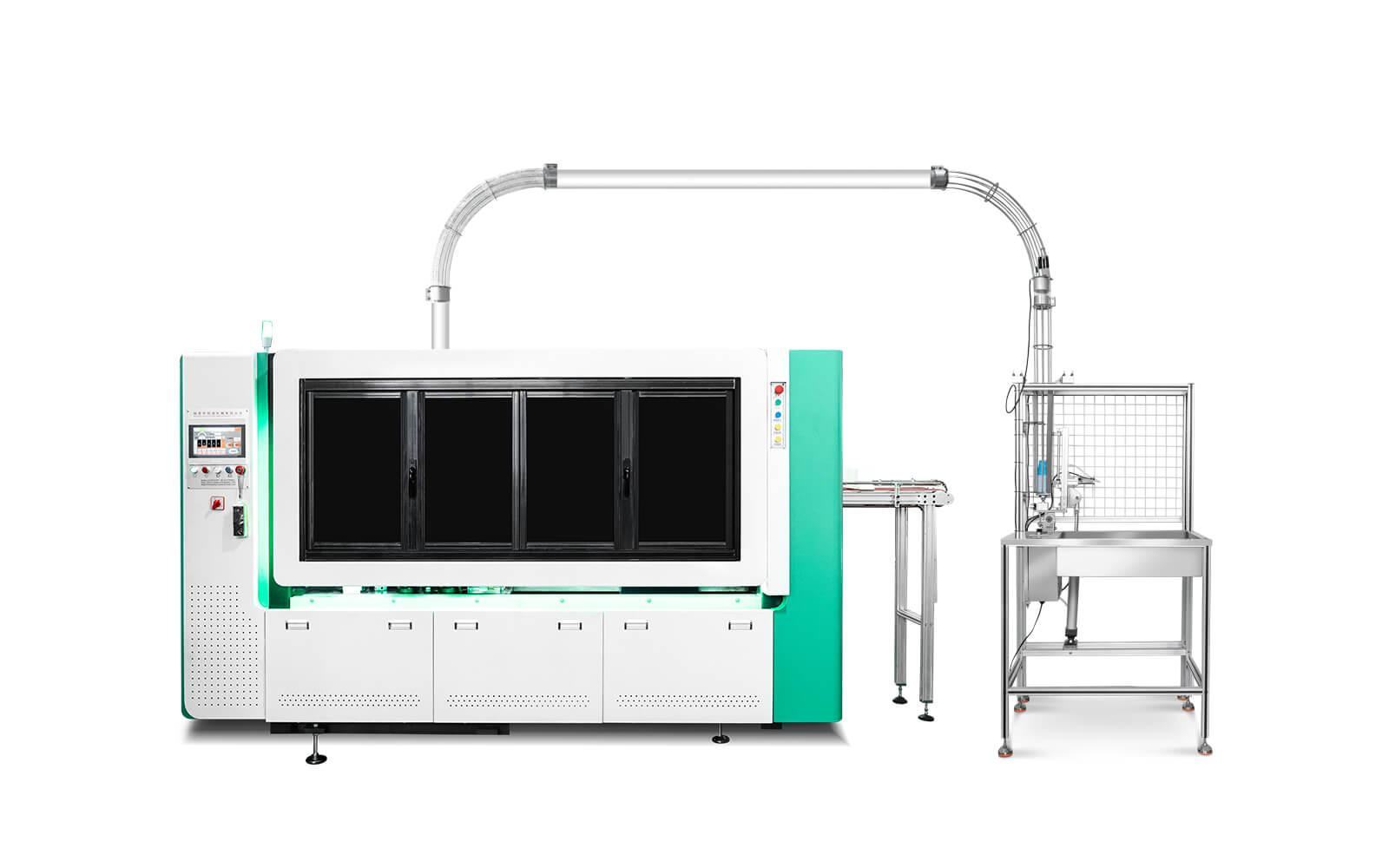

V. Is it necessary to replace the entire machine?

This is one of the most frequently asked questions by customers.

A single paper cup machine can produce multiple sizes by changing the molds.

Within the design specifications of the paper cup machine:

8oz, 12oz, and 16oz paper cups do not require a separate machine replacement for each size. By changing the mold for the corresponding capacity and using matching paper fans and cup bottom paper, the same paper cup machine can

sequentially produce paper cups of different capacities.

Production by changing molds means that the production of different sizes is carried out sequentially.

When changing sizes by changing molds:

8oz, 12oz, and 16oz can only be produced in the production schedule.

Each mold change requires machine downtime for mold replacement and adjustments.

Therefore, the mold-changing method is more suitable for:

Production of each size at different times

Or situations where order batches are relatively concentrated.

In some cases, replacing the entire machine is a reasonable and common choice.

When the following situations occur in production:

Orders for multiple capacity specifications are received simultaneously for a long period of time

Different specifications require continuous and stable supply

We want to reduce downtime caused by frequent mold changes

In these cases, configuring separate paper cup machines for different capacities is a very common and reasonable practice.

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China