-

—Key details that are easily overlooked in paper cup production I. Stable Raw Materials: The Best Protection for Your Machine In paper cup production, the problem is often not "the machine is broken," but rather fluctuations in raw material quality causing abnormal machine operation. Common...

paper cup machine

-

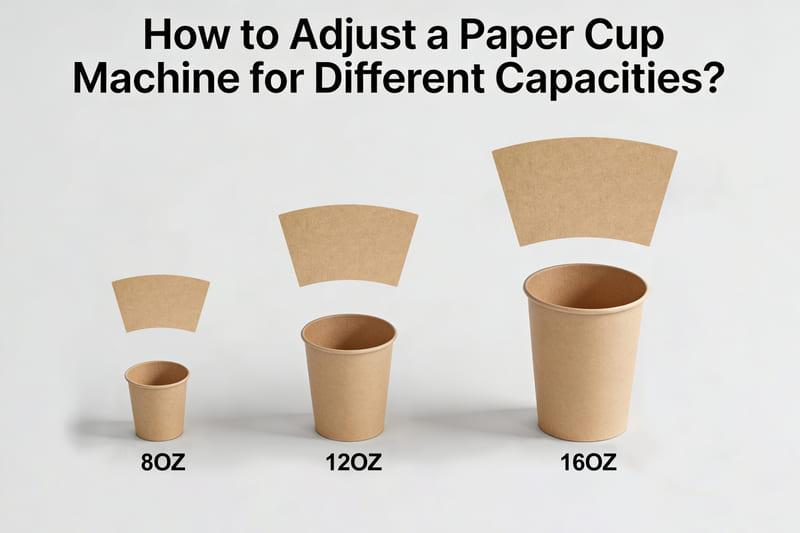

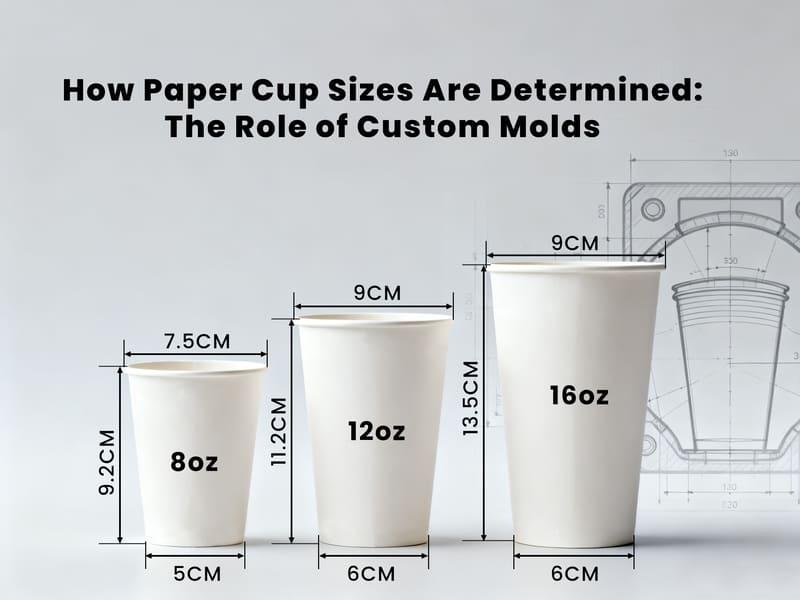

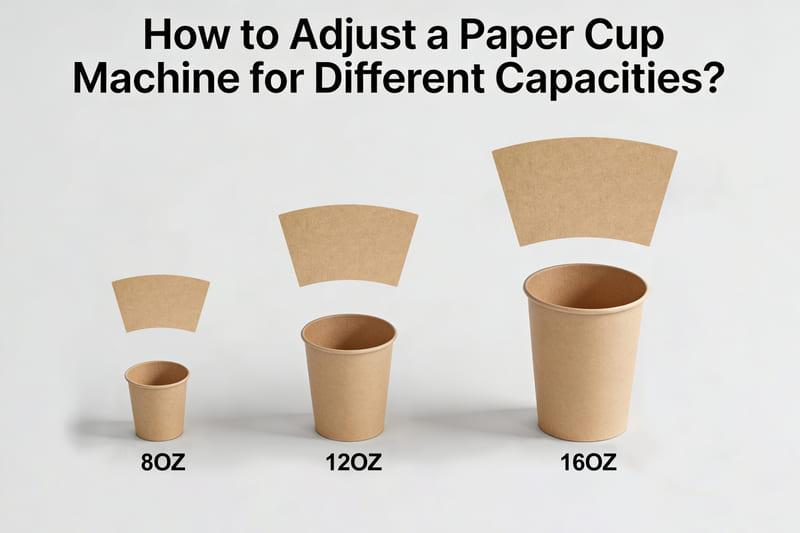

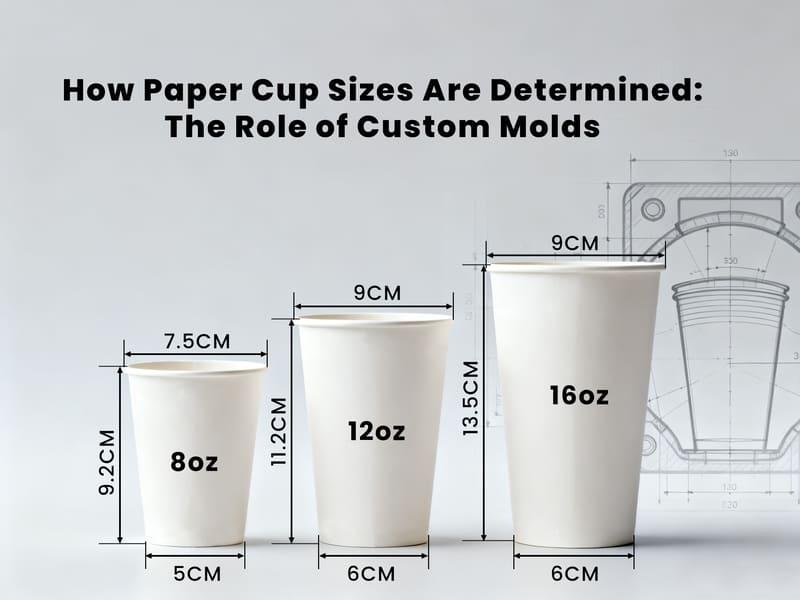

—Production analysis using 8oz / 12oz / 16oz as examples In paper cup production, size is not a simple numerical change. From 8oz to 12oz, and then to 16oz, each size change involves adjustments to the paper cup machine structure, molds, and some process parameters. I. Paper Cup Molds: The...

paper cup machine

-

1. Why Cup Size Matters The size of a paper cup not only determines its capacity but also affects its feel in hand and compatibility with lids. From 1.5oz espresso cups to 16oz coffee cups, each size requires a precise match in height, top diameter, and bottom diameter. Even a difference of just...

Paper Cup Machine Paper Cup

-

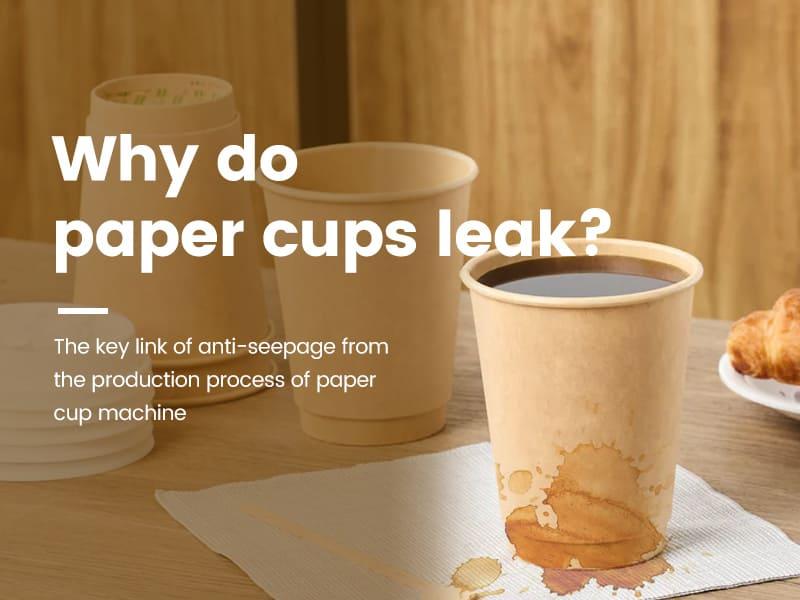

Why Do Paper Cups Leak? — Understanding the Key Stages of Leak Prevention in Paper Cup Machine Production Paper cups may look simple, but every detail in their production is closely related to leak prevention. Especially for beverage cups, even a slight leakage not only affects user experience...

Paper Cup MachinePaper Cups

-

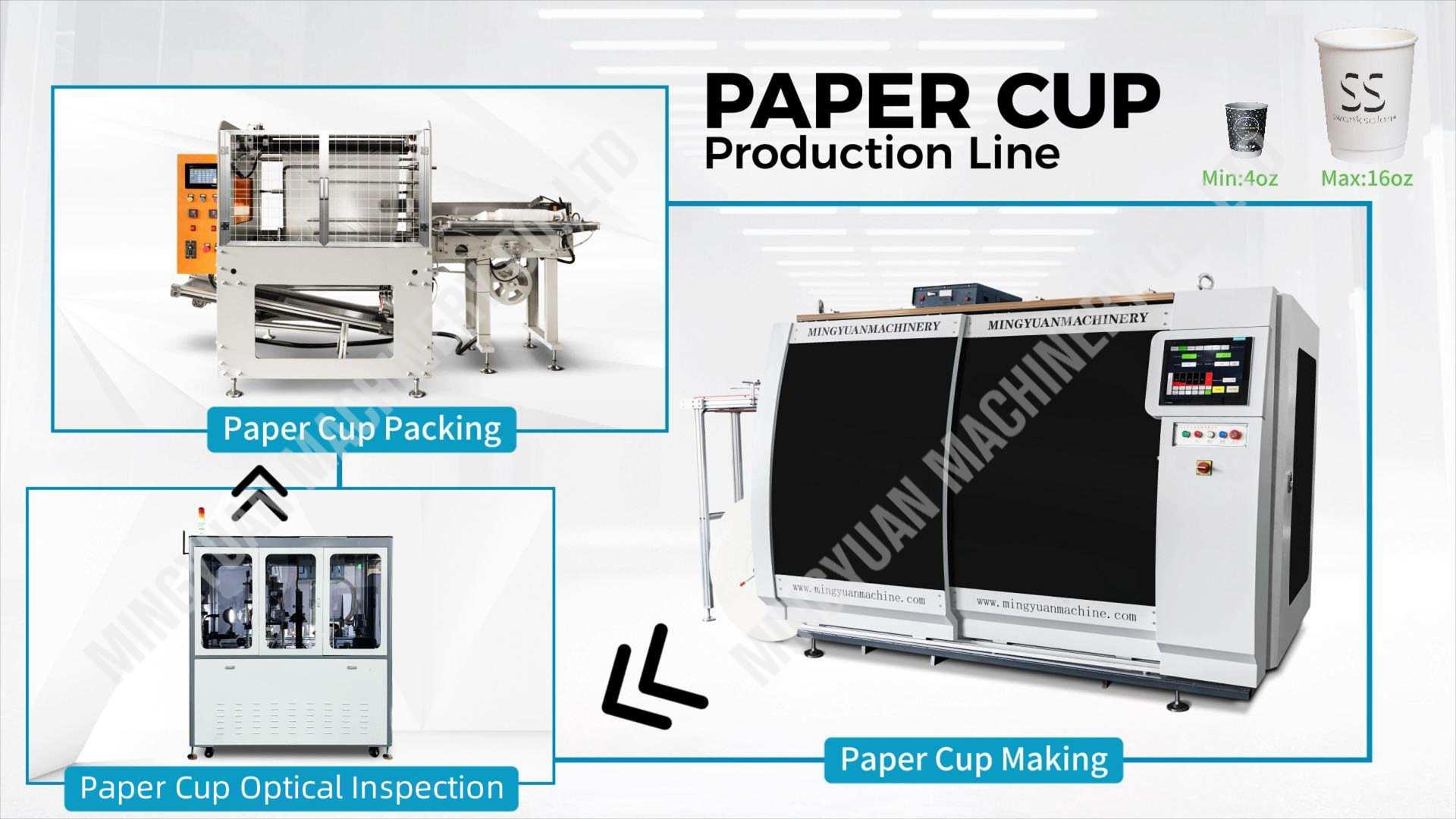

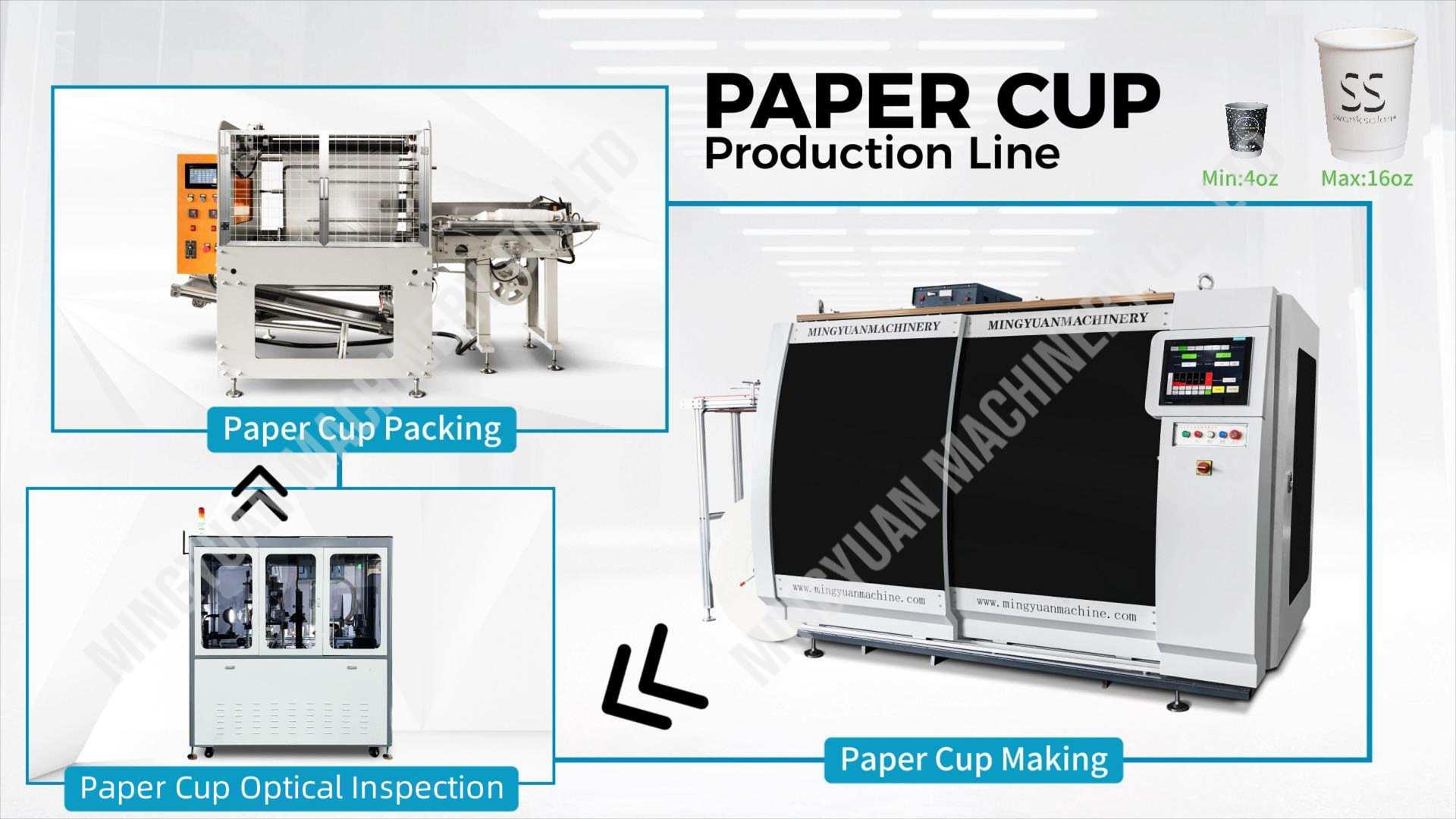

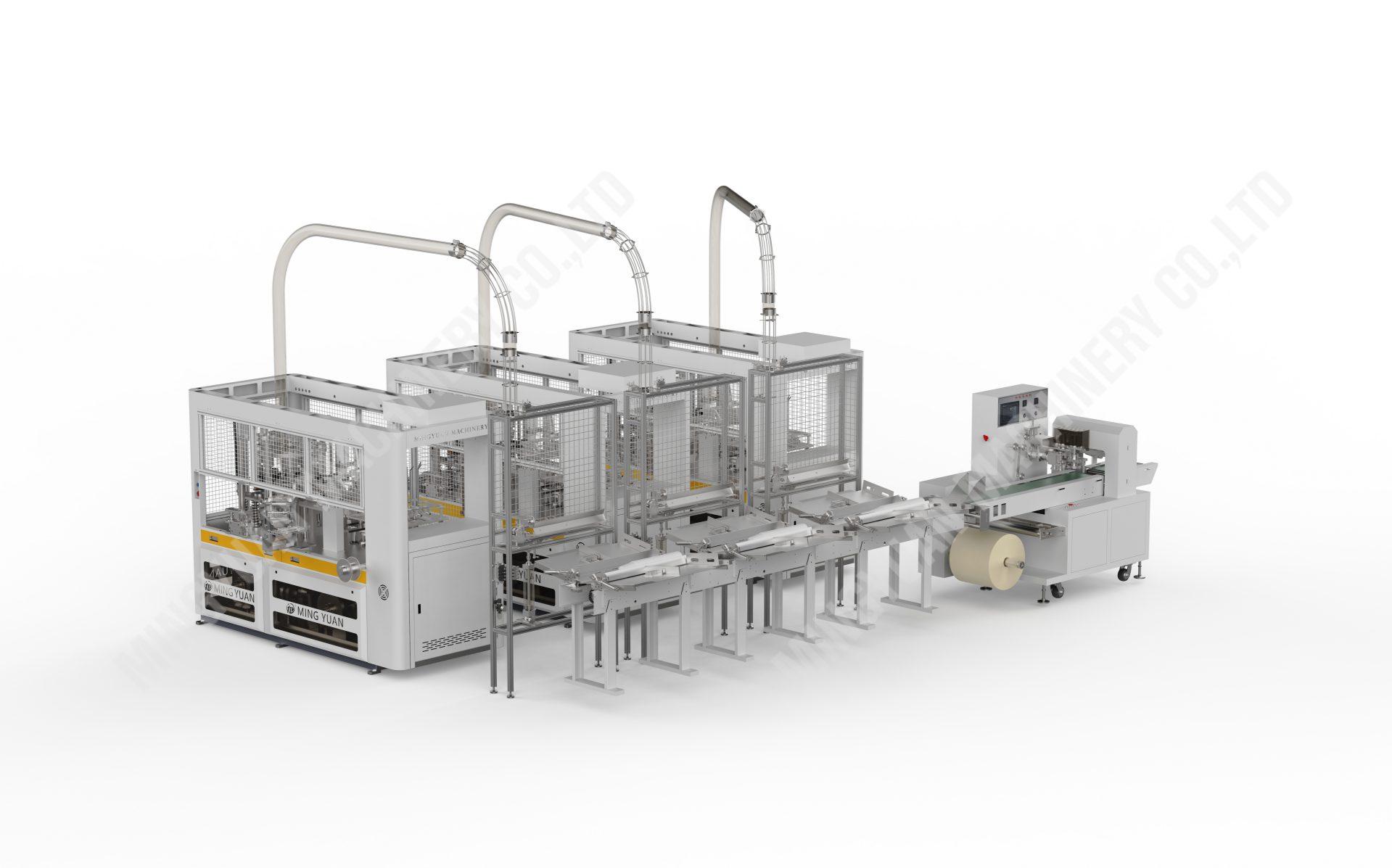

1.Take you into the MYC-180S+ automatic detection + packaging integrated production line First, according to your needs for paper cups, prepare the base paper. PE/PLA coated paper or aluminum foil paper are all suitable for this production line. Put the prepared paper fan on the conveyor...

Paper Cup Production LineOptical Inspection and Bag Packaging

-

As global environmental awareness increases, traditional plastic products are gradually being replaced by biodegradable materials, and paper cups have become one of the first choices in the food and beverage packaging industry. In this context, the efficiency and quality of paper cup production equ...

Paper cup machinePaper cup sleeve machinepaper cup production line guide

-

If you are just starting out in the paper cup industry, or are planning to build a small-scale, flexible paper cup processing plant with a limited budget, then this OCM12 + MYC-D production line is really worth a look. While maintaining output and quality, it does not require too high an investment...

paper cup machinepaper cup sleeve machinePaper cup production line

-

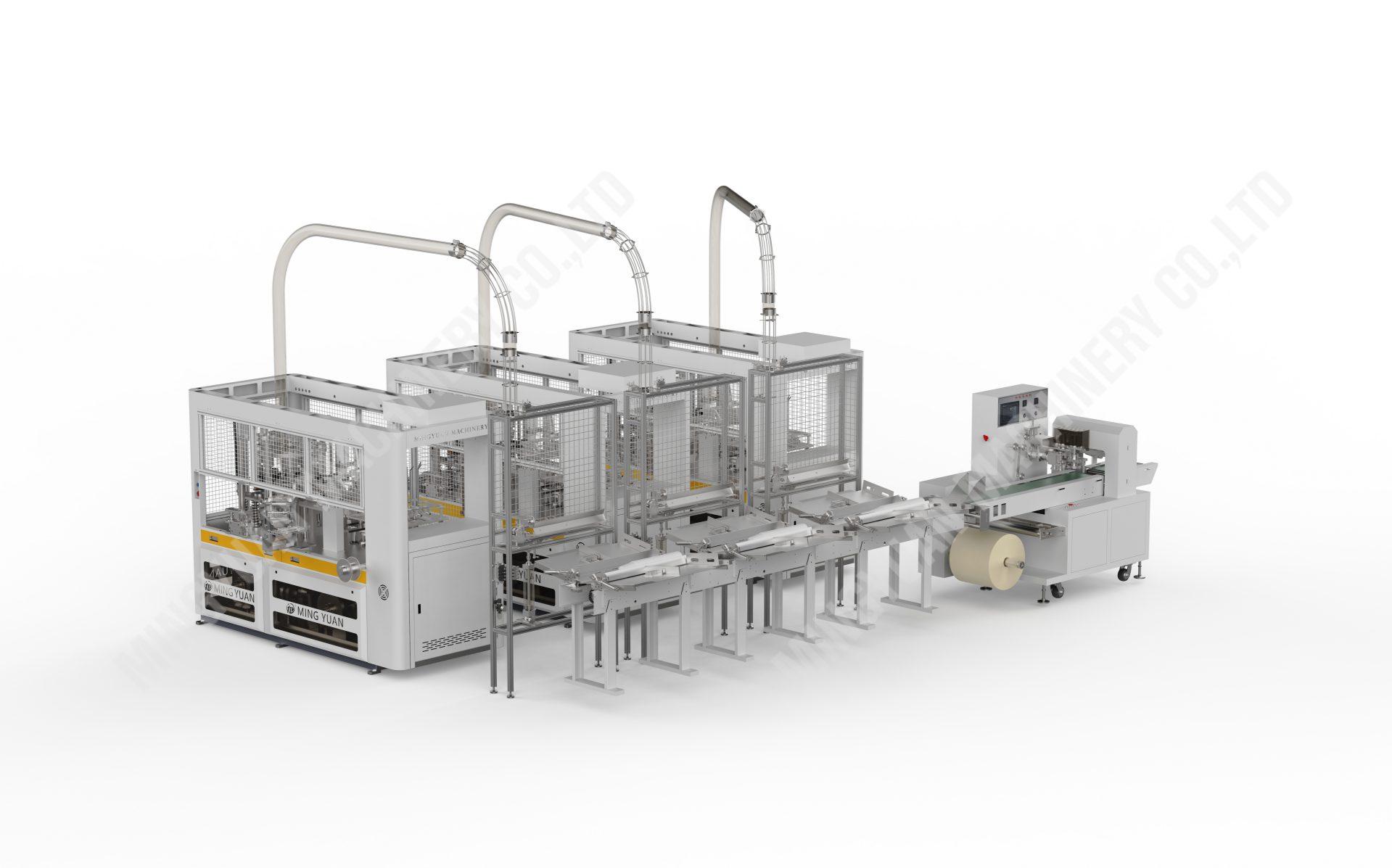

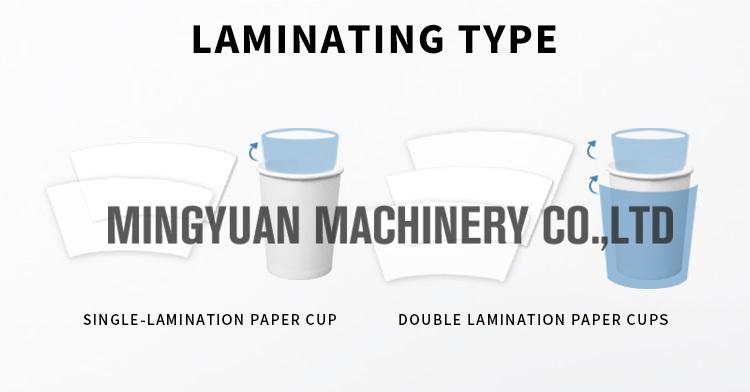

Three Machines, Three Sizes:OCM12 High-end Paper Cup Machine*3 + 450X Paper Cup packaging Machine.The production line consists of three OCM12 high-end paper cup machines,each producing a different cup size simultaneously (e.g., 8oz, 12oz, 16oz). No mold change, no downtime. All cups are transferred to a 450X rotary knife packaging machine, which automatica...

-

We are very pleased to announce that Mingyuan Machinery will participate in the China Indonesia Trade Fair 2025 held at the Jakarta International Exhibition Centre from June 4 to June 7, 2025! Booth number: C1A111 Exhibition time: June 4 – June 7, 2025 Exhibition hall: HALL C1 At this exh...

Mingyuan Machinery

-

In the paper cup production process, choosing the right paper cup machine is crucial for production efficiency, product quality and ease of operation. Single turnplate paper cup machine and double turnplate paper cup machine are two common types of paper cup machines, each with unique features and...

double turnplate paper cup machine

-

Part 1: Delivery time, after-sales service and paper cup machine parameters introduction During the initial communication with us, we will give priority to introducing you to the delivery time, after-sales service details and main parameters of the relevant models that you are most concerne...

paper cup machine

-

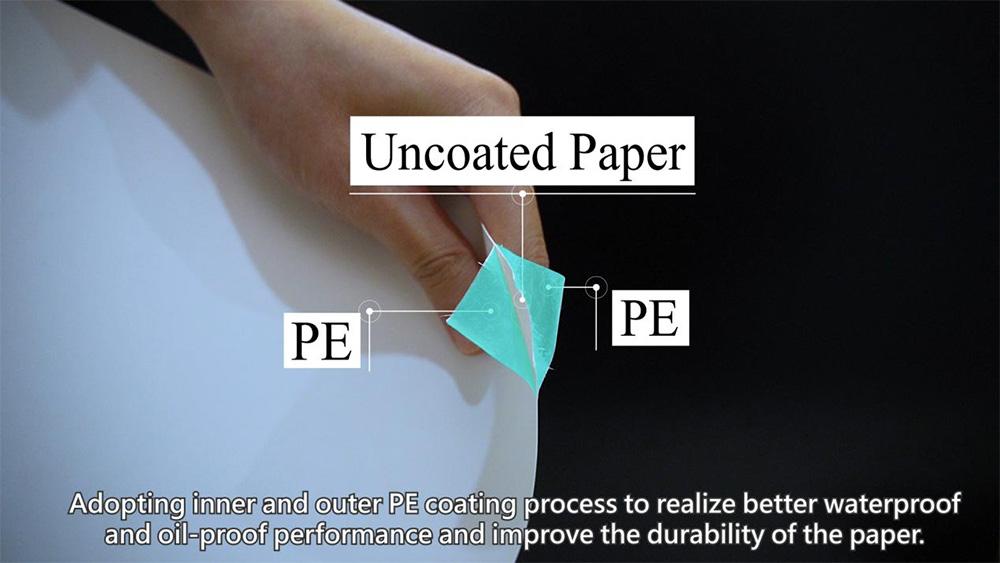

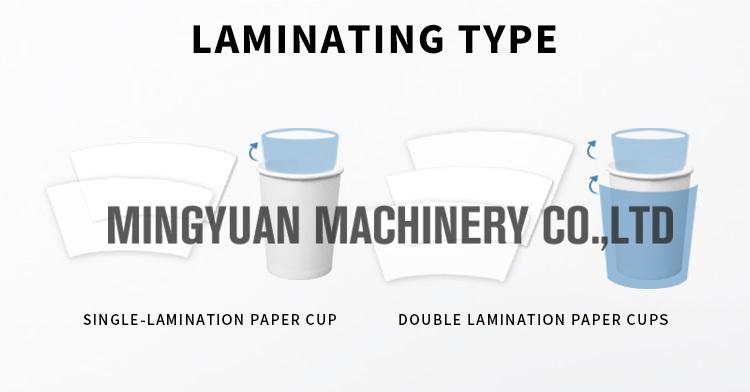

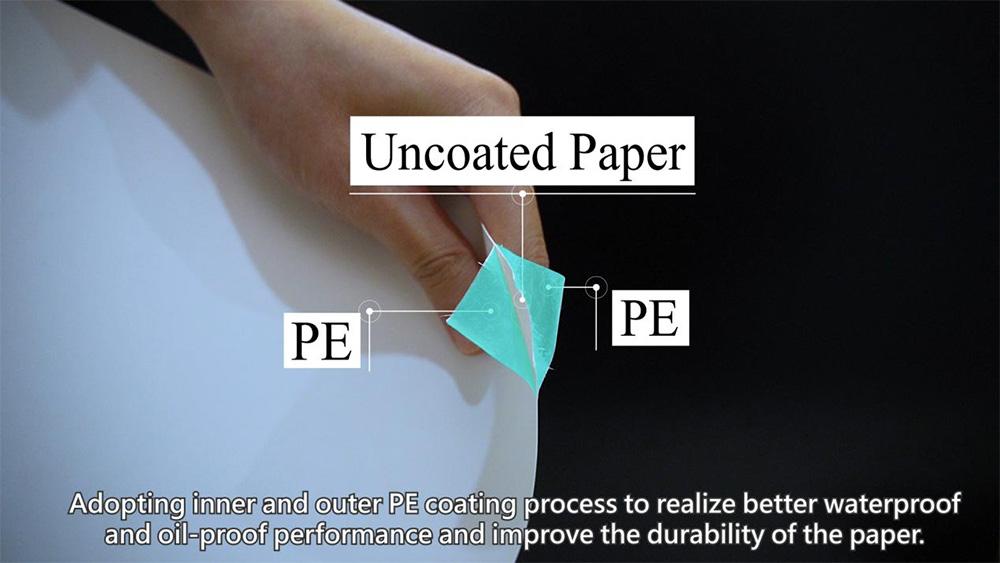

In paper cup production, it is very important to select high-quality raw materials because it directly affects the quality and performance of the product. Only raw materials that meet the standards can give full play to the performance of paper cup machines. Paper cup machines transform food-grade...

paper cup machinepaper cup raw materials

-

Paper Cup Forming The paper cup machine processes the raw materials into paper cups through the following steps:...

Paper cup machine related knowledge

-

1. The pressure of the knurling wheel is too small During the paper cup forming process, the pressure of the knurled wheel is crucial to the sealing of the bottom of the paper cup. If the pressure of the knurling wheel is too small, the paper at the bottom and the cup wall cannot be tightly combin...

Paper cup machinePaper cup forming

-

With the increasing awareness of environmental protection and the widespread use of disposable paper cups, the demand for paper cup machines continues to increase. As the core equipment for paper cup production, paper cup machines have very strict requirements for raw materials. This article will i...

Paper Cup Making MachinePaper cup raw materials

Tel: +86-19057361870 / +86 577 65567060

Tel: +86-19057361870 / +86 577 65567060  Email: george@paper-cupmakingmachine.com

Email: george@paper-cupmakingmachine.com MP/WhatsApp: +86-19057361870

MP/WhatsApp: +86-19057361870 Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China

Manufacturer Address:No.1588, Huaming Road, Feiyun Street,Ruian City Zhejiang Province -325200 China